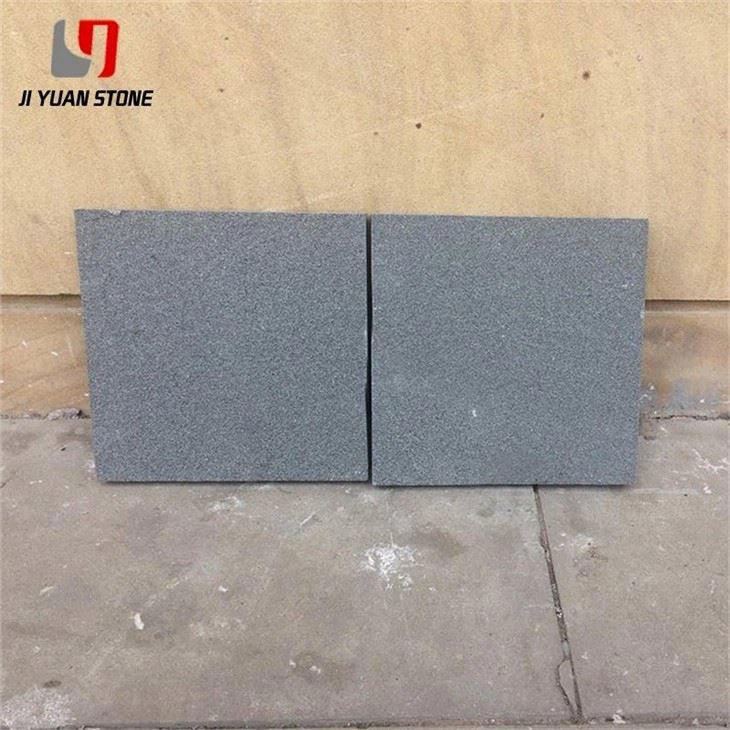

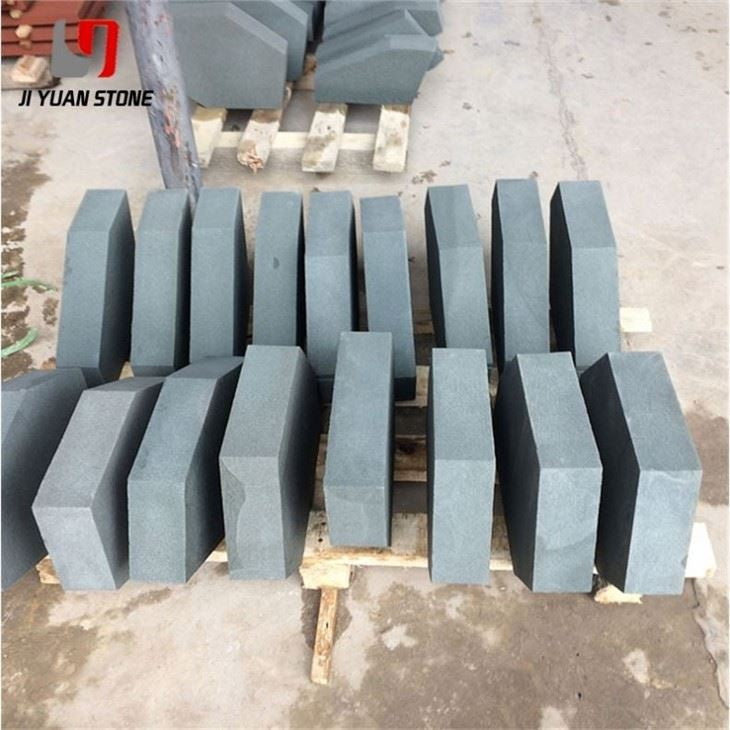

Dark Grey Sawn Sandstone

Dark Grey Sawn Sandstone

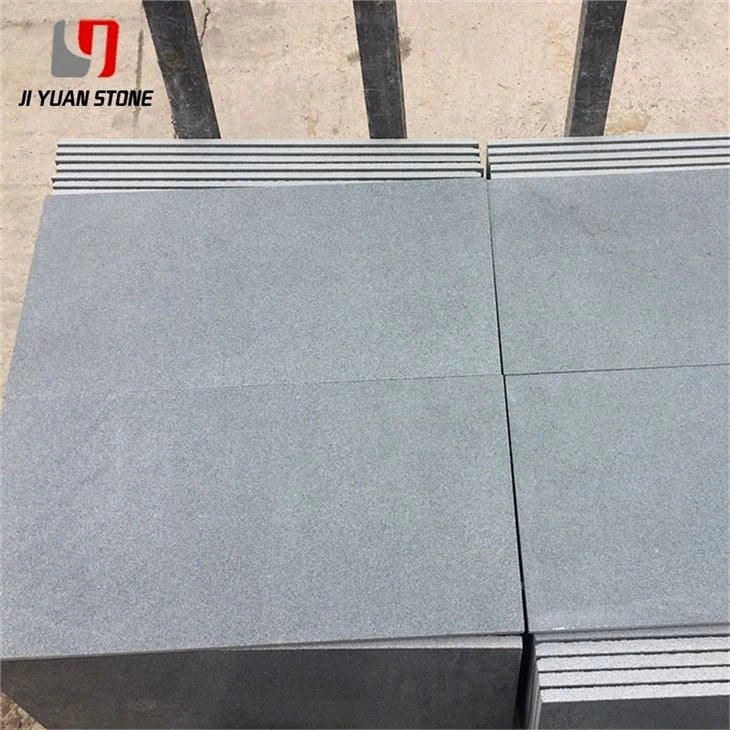

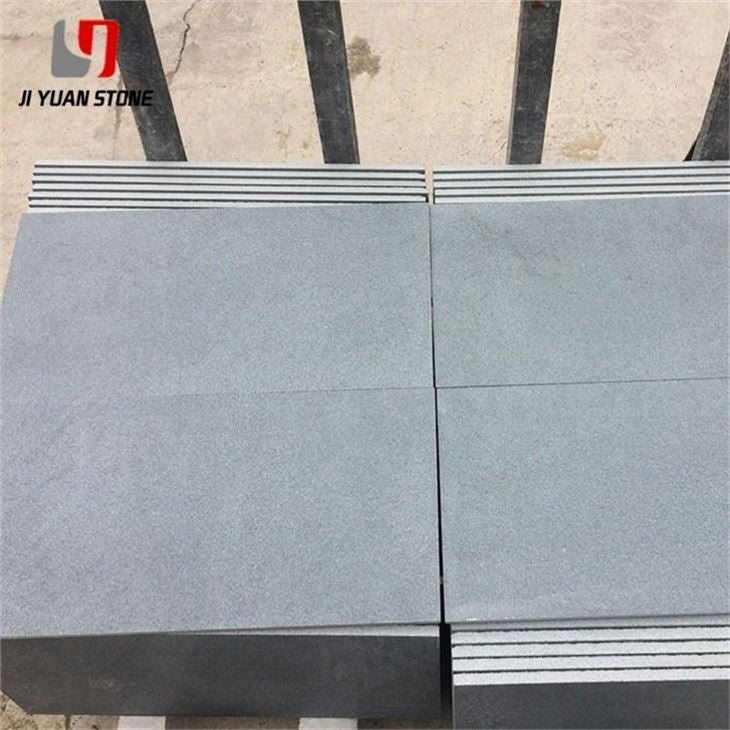

Discover the timeless elegance of our Dark Grey Sawn Sandstone. With its sleek, modern appearance, this sandstone is perfect for any outdoor or indoor project. Its deep grey color adds a sophisticated touch while its sawn finish creates a smooth texture. Upgrade your space today with this versatile and durable stone.

| Feature | Details |

|---|---|

| Material | Natural Sandstone |

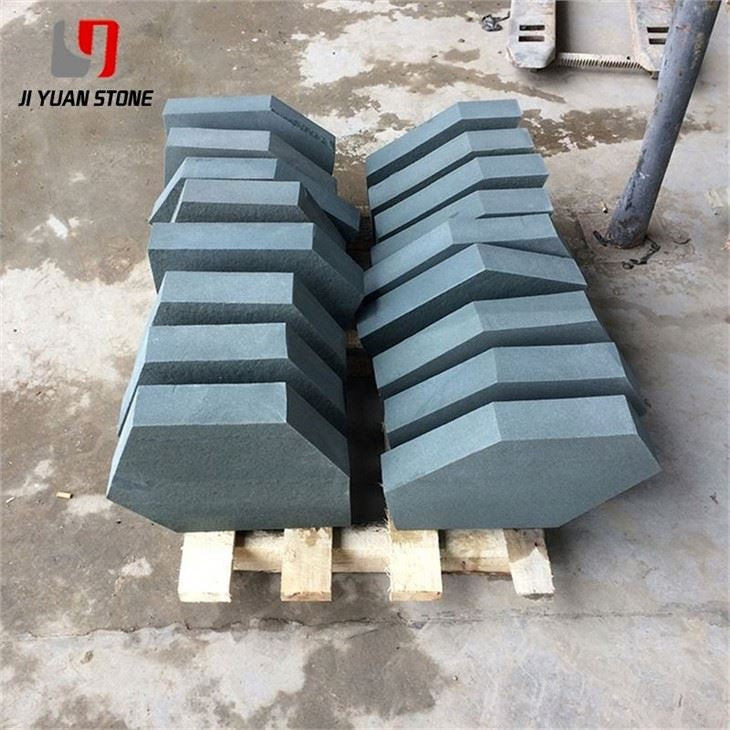

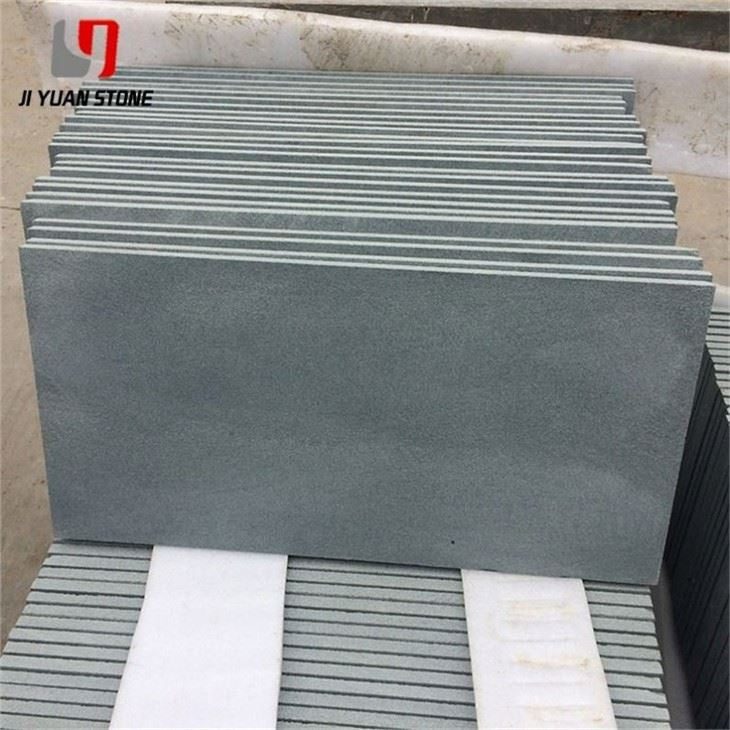

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Finished | Honed, Split, Sandblasted, Sawn, Antiqued, Pineapple, etc. |

| Dimension |

|

| Usage | Interior & Exterior Decoration |

| Quality Control |

Thickness Tolerance:+/-0.5mm,+/-1mm; All Products Checked by Experienced QC |

| MOQ | Welcome Small Trail Orders |

| Size | Customized Pls contact us for the newest catalog of sandstone,marble,granite,quartz,mosaic,limestone,travertine etc |

| Sample | Contact Us For Free Samples |

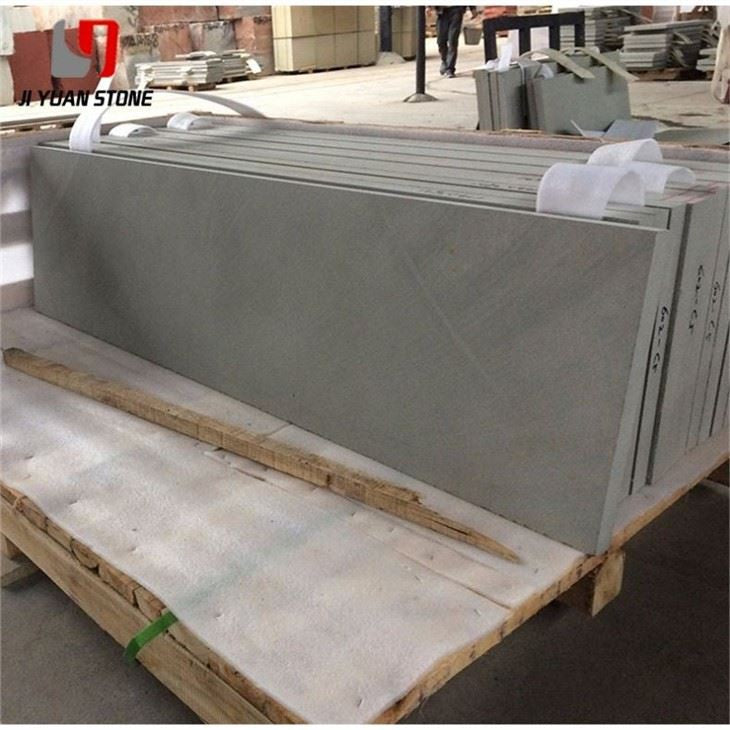

| Package | Standard Exporting Seaworthy Package ( Inner: Plastic Film and Foam; Outer: strong seaworthy wood Crates or Pallets.)Payment |

| Payment | T/T, L/C, Escrow, Western Union |

| Delivery | Within 2 Weeks After Deposit |

- Material Selection

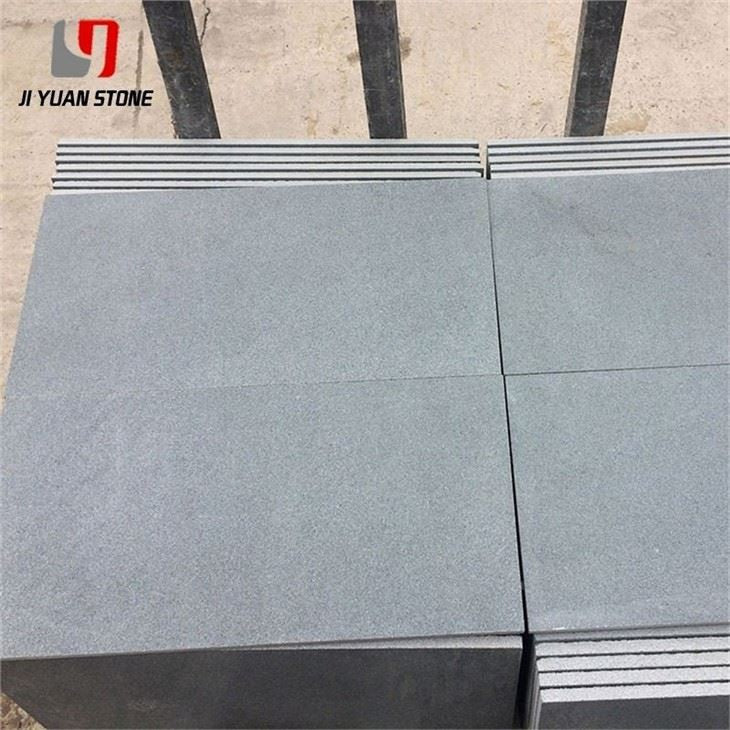

o Select large stone slabs with obvious patterns.

- Grinding and Polishing

o Grind and polish the front and back sides of the slabs.

o The front of the single-size slab is processed into a smooth surface.

o The bottom surface of the double-size slab is also processed into a smooth surface.

o Ensure that the number of front and back surfaces is split evenly (half and half).

- Alignment Processing

o Select half of the processing pattern for the single-size large plate.

o Select the other half of the processing pattern for the double-size large plate.

o Choose the large plate for processing according to the sequence number.

- Verification of Processing Effect

o During processing, refer to the numbering diagram for the processing order.

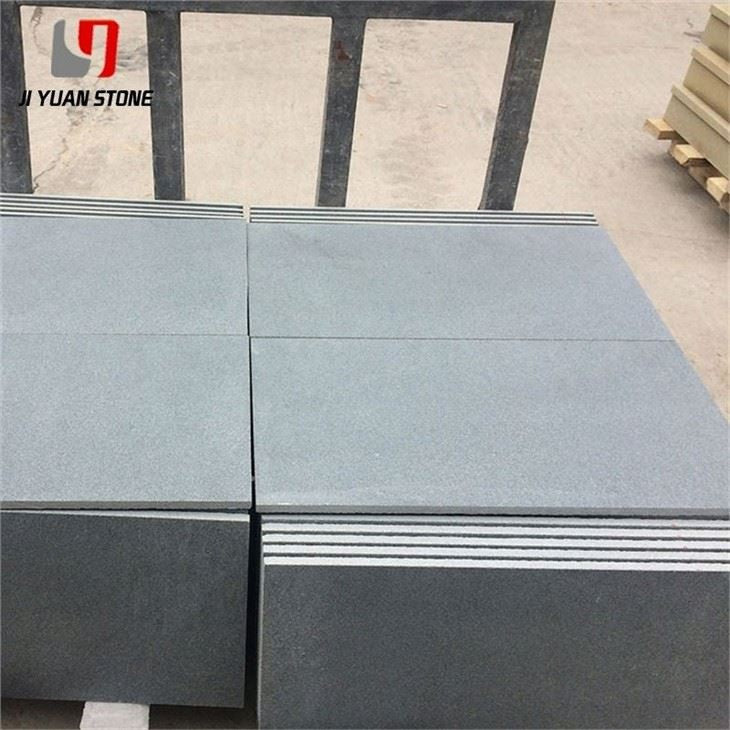

o Place the cut dark grey sawn sandstone on the ground in sequence, ensuring close splicing and butt joints.

o After confirming the effect, mark the bottom of the sandstone with the corresponding number and arrow direction.

-

Reverse Waterproof Adhesive Treatment

5.1 Preparation

o Weigh the liquid and powder of the waterproof adhesive according to the required proportions.

o Mix them thoroughly with an electric mixer (add the liquid first, then add the powder while stirring).

o Let the mixture stand for 5-10 minutes until bubbles are eliminated before applying.

Share