1

/

of

16

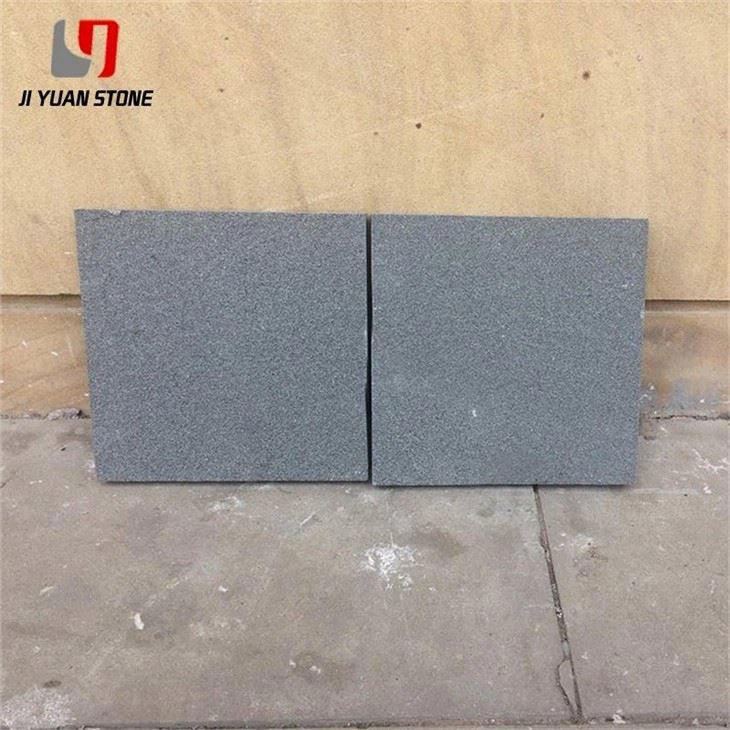

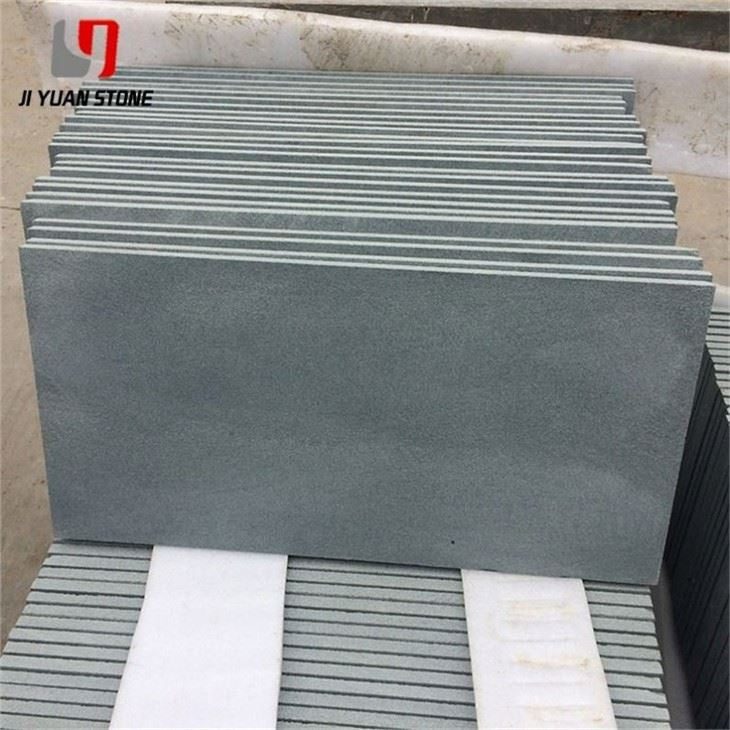

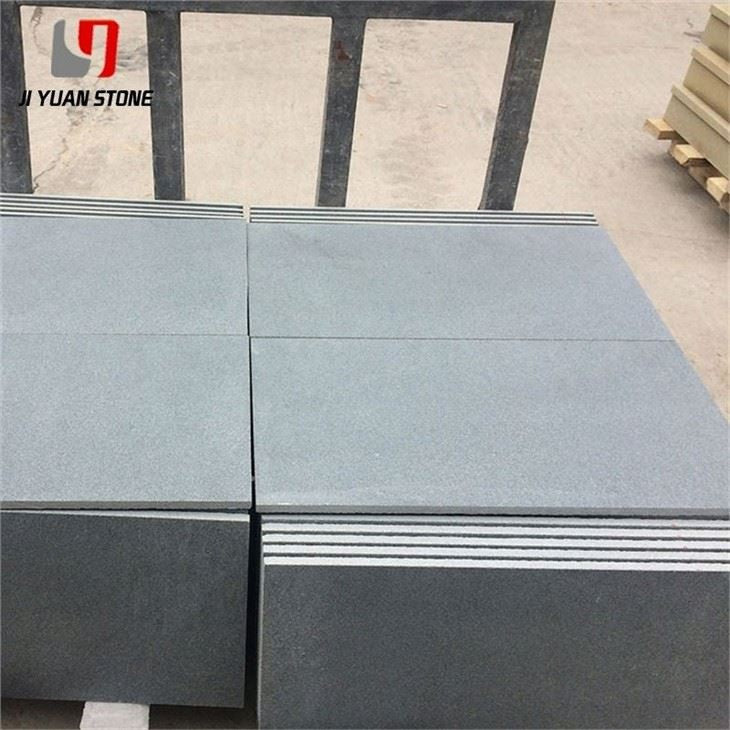

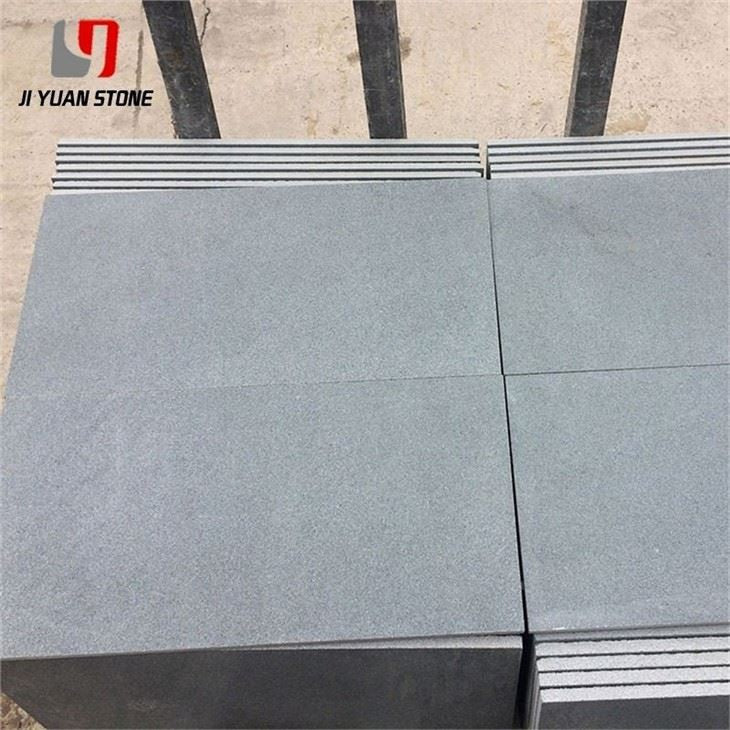

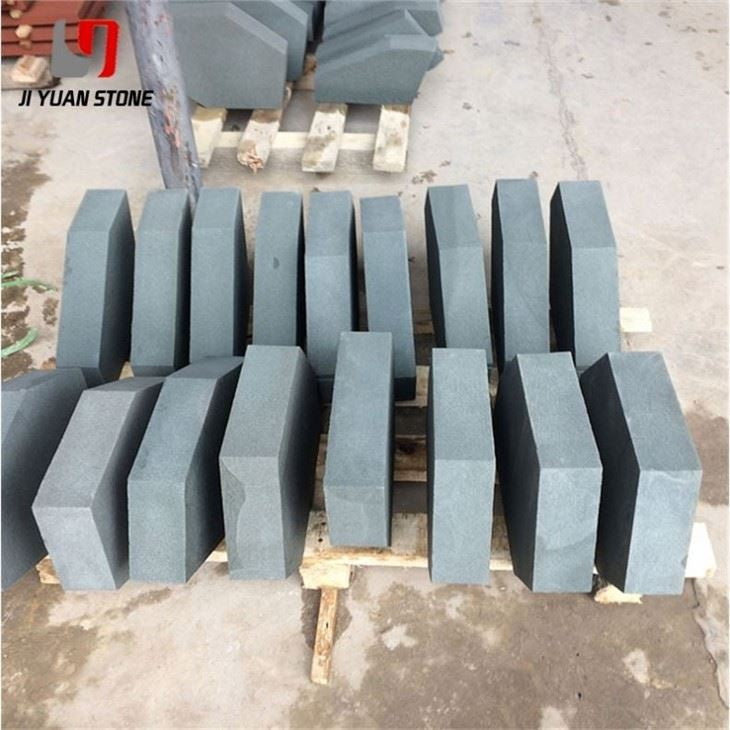

Dark Gray Sandstone

Dark Gray Sandstone

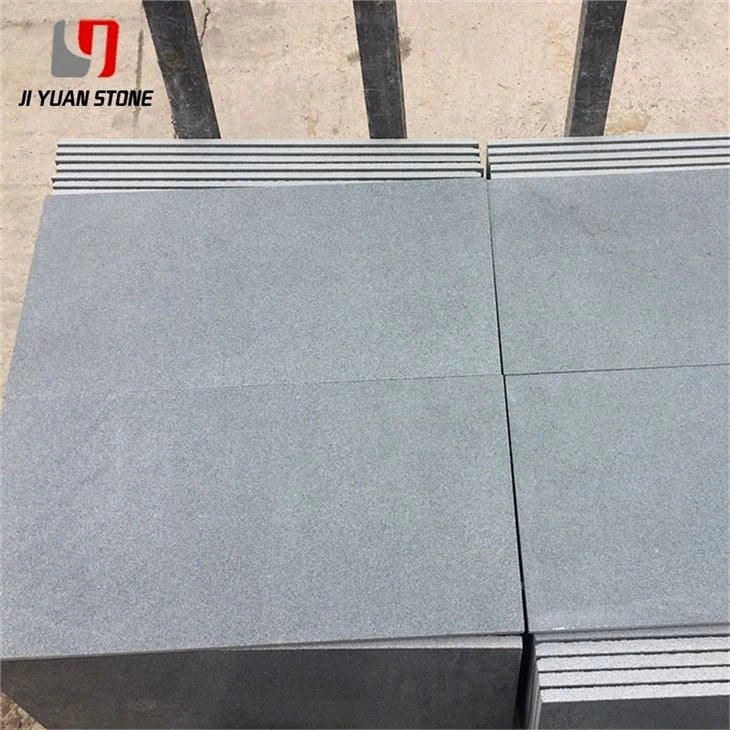

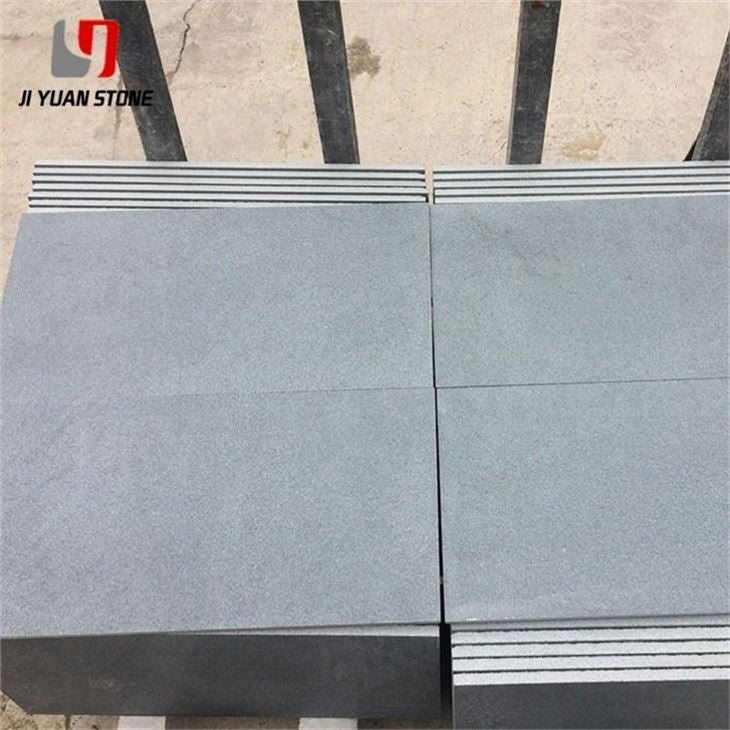

Discover the timeless elegance of our Dark Grey Sawn Sandstone. With its sleek, modern appearance, this sandstone is perfect for any outdoor or indoor project. Its deep grey color adds a sophisticated touch while its sawn finish creates a smooth texture. Upgrade your space today with this versatile and durable stone.

| Feature | Details |

|---|---|

| Material | Natural Sandstone |

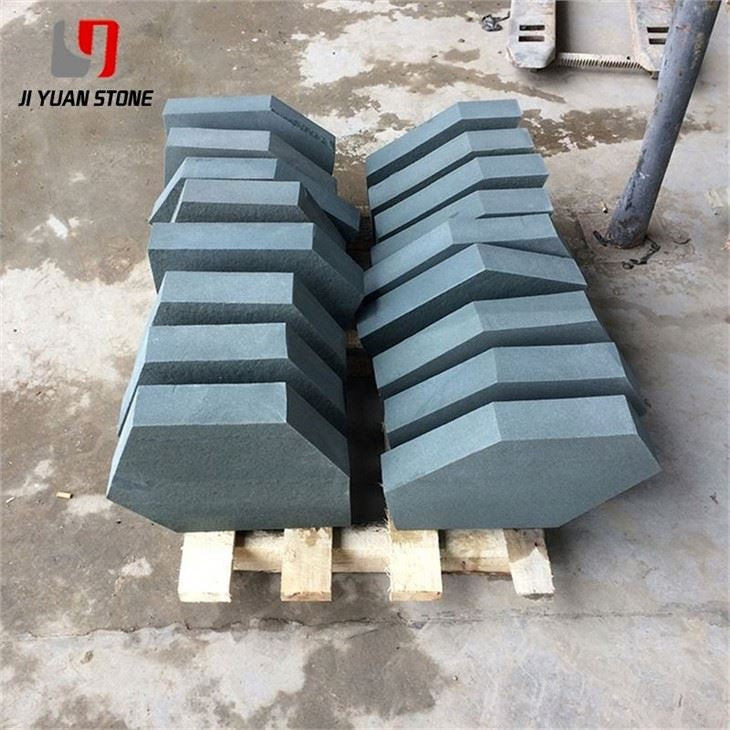

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Finished | Honed, Split, Sandblasted, Sawn, Antiqued, Pineapple, etc. |

| Dimension |

|

| Usage | Interior & Exterior Decoration |

| Quality Control |

Thickness Tolerance:+/-0.5mm,+/-1mm; All Products Checked by Experienced QC |

| MOQ | Welcome Small Trail Orders |

| Size | Customized Pls contact us for the newest catalog of sandstone,marble,granite,quartz,mosaic,limestone,travertine etc |

| Sample | Contact Us For Free Samples |

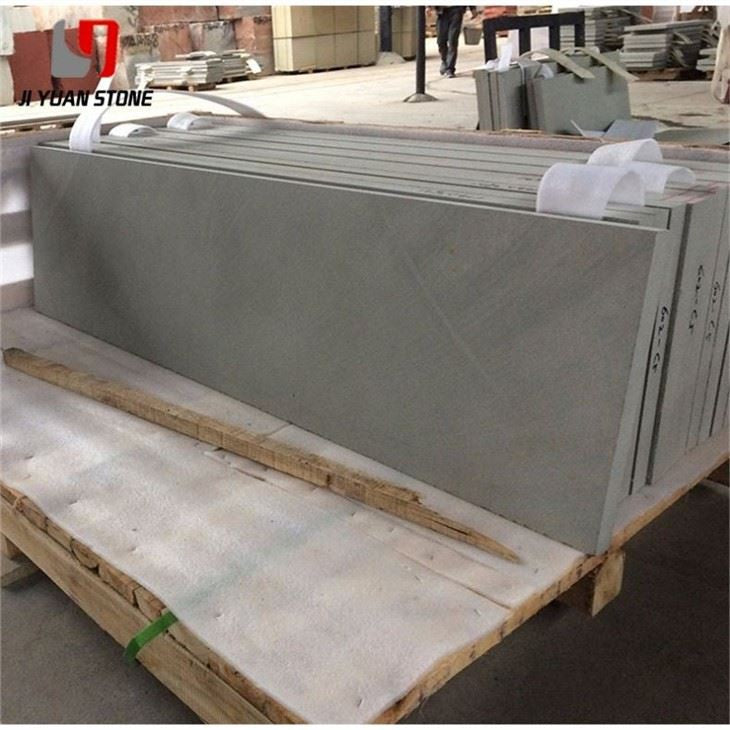

| Package | Standard Exporting Seaworthy Package ( Inner: Plastic Film and Foam; Outer: strong seaworthy wood Crates or Pallets.)Payment |

| Payment | T/T, L/C, Escrow, Western Union |

| Delivery | Within 2 Weeks After Deposit |

Dark Gray Sandstone Cutting & Installation Guidelines

- Cutting Process

- Dark gray sandstone must be cut with an infrared cutting machine to prevent edge explosion and other issues.

- Stone Layout & Design

- The layout plan should be drawn according to the stone embryo's size to minimize loss.

- If the loss is too large, the design should be adjusted accordingly.

- For ground installations, dark gray sandstone should preferably not exceed 800×800mm.

- If the stone requires special-shaped paving, a modular approach should be used to minimize waste.

- Arc-Shaped Stone Parquet

- Parquet stone should have a reasonable seam design.

- It should be customized by the manufacturer and cut using a professional water jet for accuracy.

- Surface Cleaning

- Residual impurities such as emery, dust, and debris should be cleaned with clean water before installation.

- Drying Process

- The cut stone should be placed vertically in a ventilated and dry area for at least 48 hours before stacking.

- If the construction schedule is tight, a drying room or a blower can be used to accelerate the drying process.

- Stone Texture Control

- Certain stones like snow white and fish maw white are difficult to repair with glue.

- It is best to use powdered original stone mixed with glue for repairs.

- If the texture cannot be seamlessly connected, modification should be avoided to preserve the natural appearance of the dark gray sandstone.

- Improper modifications may disrupt the original texture and compromise the final look.

Share