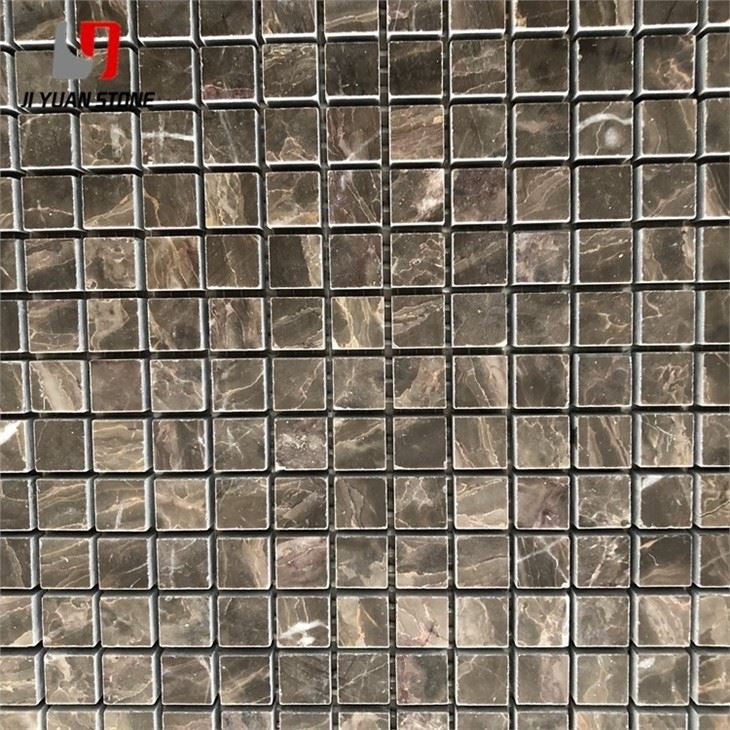

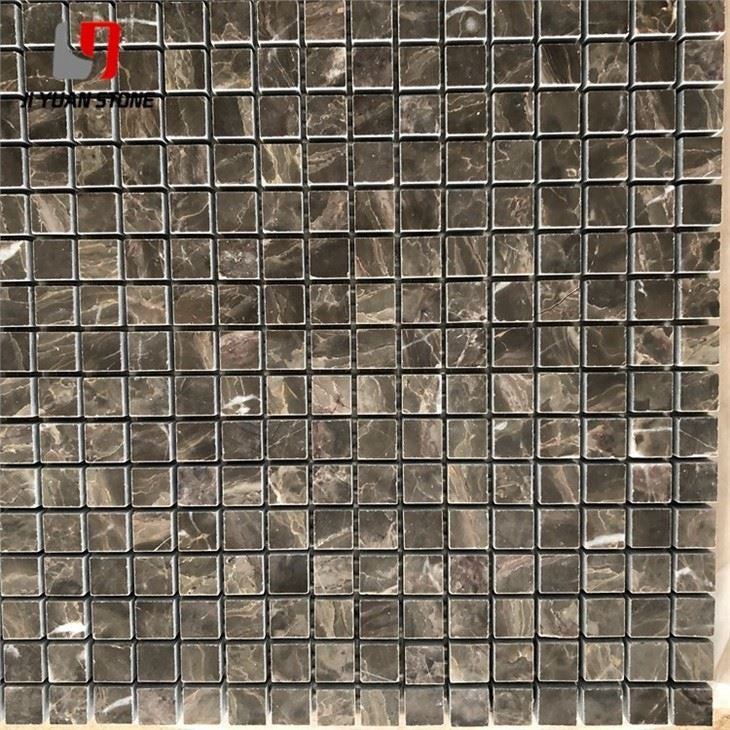

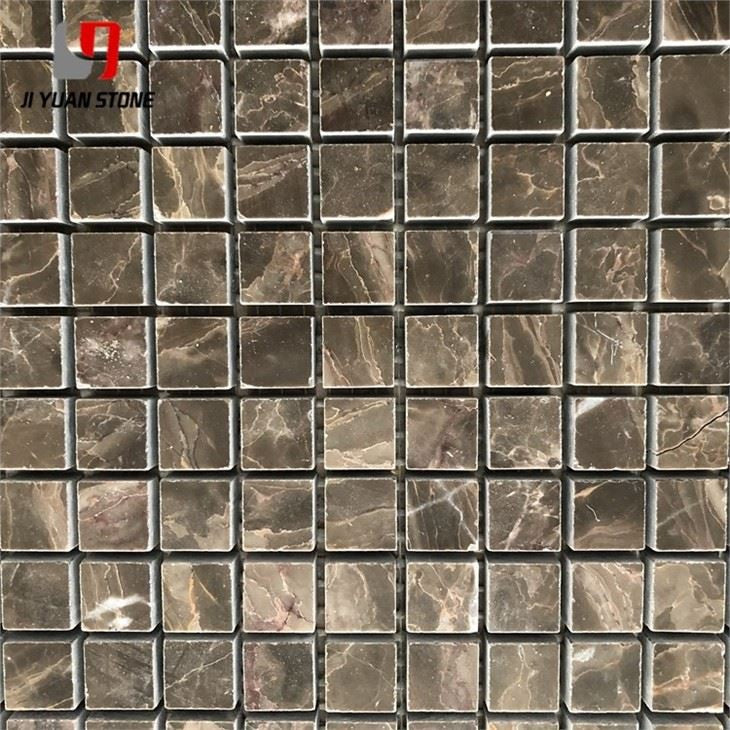

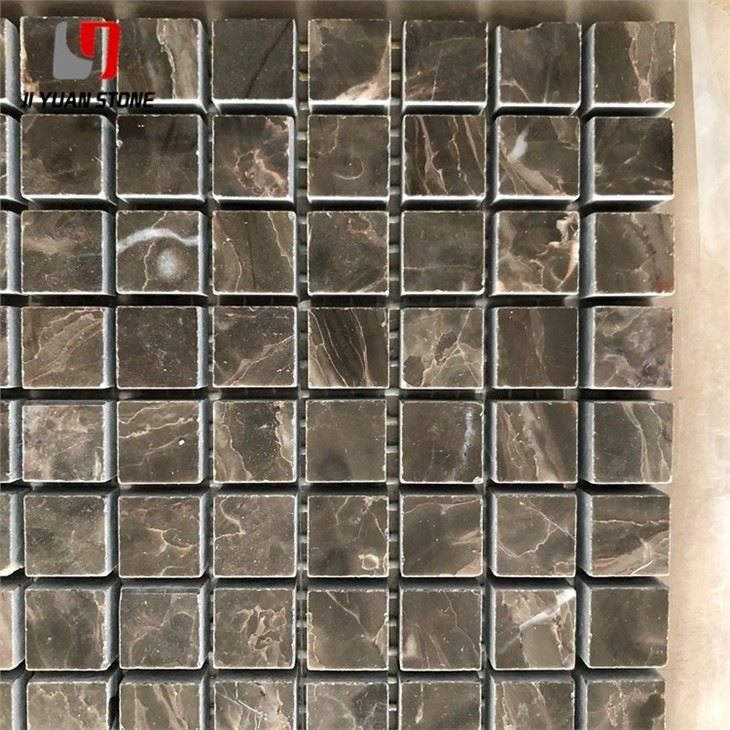

Dark Brown Marble Mosaic

Dark Brown Marble Mosaic

Create a sophisticated and elegant look with our Dark Brown Marble Mosaic. Made from high-quality dark brown marble, this mosaic is both stylish and durable. Perfect for adding a touch of luxury to any room, this mosaic is a must-have for any design-savvy individual.

| Feature | Details |

|---|---|

| Material | Natural Marble Stone,Travertine,Limestone |

| Colour | As pictures show or customized |

| Shape | Square, Basketweave, Mini brick, Modern brick, Herringbone, Subway, Hexagon, Octagon, Mixed, Grand fan, Penny round, Hand clipped, Tesserae, Random strip, River rocks, 3D cambered, Pinwheel, Rhomboid, Bubble round, Circle bubble, Stacked, etc... |

| MOQ | Unrestricted |

| Warranty | 3 years |

| After-sale Service | Online technical support |

| Size | Customized Size |

| Style | Modern |

| Occasion | Wall or Floor |

| Project Solution Capability | Total solution for projects |

| Application | Bathroom |

| Design Style | Modern |

| Place of Origin | China |

| Model Number | Brass Marble Waterjet Mosaic |

| Shape | Irregular |

Our products range includes mosaic, tiles, marble/granite flooring, ledger stone, sandstone cladding, and other stone works like sinks and accessories. We are also an expert for the DIY self-adhesive system which covers products like a mosaic, wood planks, etc.

With our professional and dedicated team, standing on our own factories and deeply cooperated manufacturers, we are trying our best to form a chain of products that can match up customers’“one-stop” shopping demand. We are here in China, we are looking forward to working with you in China as we are capable in China ~! We are one of the “best partners” for all willing hearts for beautiful & decorative material~!

Installation and Reinforcement of Traditional Dark Brown Marble Mosaic

The installation and reinforcement of dark brown marble mosaics are completed simultaneously, following a structured process to ensure strength and durability.

1. Base Layer Preparation

- Leveling the mortar layer is crucial to ensure flatness, including corner accuracy.

- Once the leveling mortar sets, a thin layer of plain cement slurry is applied.

2. Mosaic Installation

- Mosaic plates are placed onto the prepared surface.

- Using a wooden trowel (wood crab), the tiles are firmly tapped to:

- Force the primer upwards into the gaps between mosaic particles.

- Ensure flush alignment with the tile surface (as shown in Figure 1).

- Form a solid bond between the mosaic components and the cement.

3. Curing & Finishing

- After the cement cures, the surface is moistened using a water spray to soften the adhesive under the kraft paper.

- The kraft paper is removed, and gaps are checked and filled with cement clear slurry.

- Finally, the surface is rubbed with wood chips to remove residual glue, ensuring a clean, polished finish.

This traditional technique allows installation, bonding, and reinforcement to be completed in one step, offering simplicity, strength, and long-lasting durability.

Share