Cutting Terrazzo Slab

Cutting Terrazzo Slab

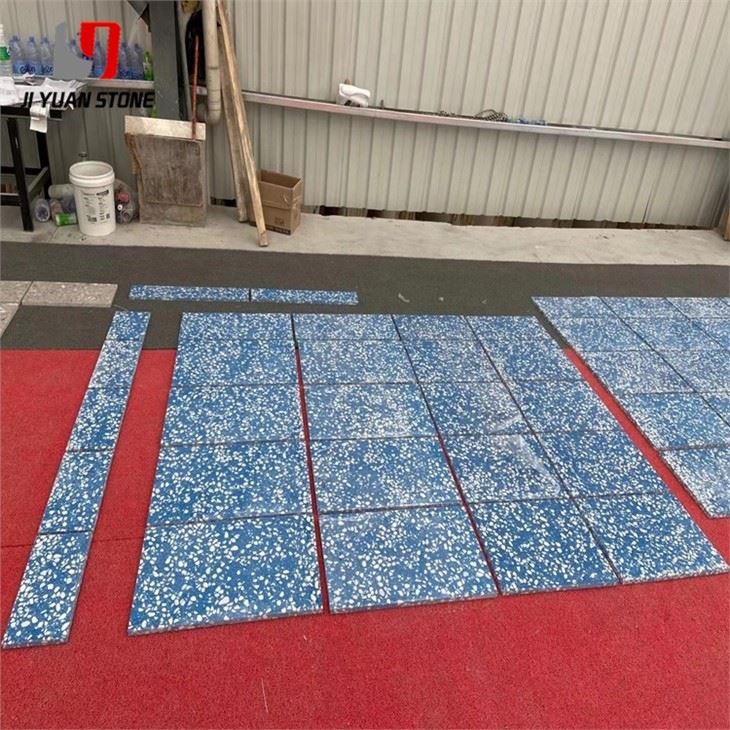

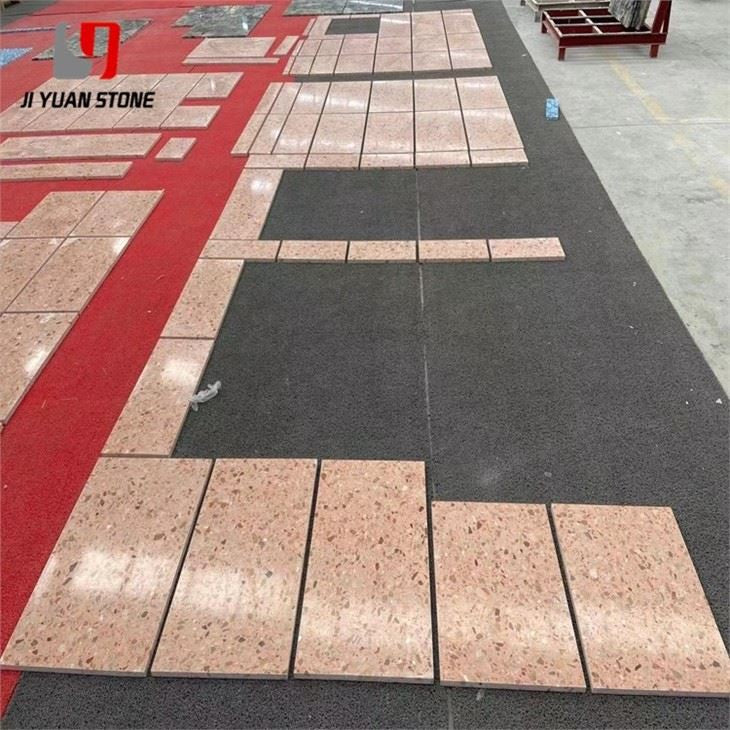

Colored Cutting Terrazzo Slab – High-Strength, Customizable, and Beautifully Versatile

Introducing our Cutting Terrazzo Slab, designed for precision and efficiency. This slab is engineered with expert knowledge and is ready to tackle any project. With its sleek design and cutting-edge technology, it's the perfect addition to any workspace. Cut through your projects with ease using our Cutting Terrazzo Slab.

| Feature | Details |

|---|---|

| Material | Terrazzo |

| Surface Finish | Polished,Honed |

| Slab standard size | 3200*1600mm/2700*1800mm/2400*1600mm/2400*1200mm |

| Tile standard size | 800*800mm/900*900mm |

| Available Thickness | 2cm/2.5cm/3cm or other thickness as customization. |

Our Colored Cutting Terrazzo Slab offers a perfect blend of durability, aesthetic appeal, and design flexibility. Ideal for modern interior and exterior applications, this upgraded terrazzo product is engineered to last while delivering elegance and color variety.

Colored Cutting Terrazzo SlabColored terrazzo is a high-strength, durable, and aesthetically appealing material made by mixing cement with colored terrazzo chips. Through molding, curing, grinding, and polishing processes, it is transformed into a versatile decorative solution for floors, walls, countertops, and much more.

1. Features of Colored Terrazzo✔ Exceptional Strength & Durability – Built to withstand heavy use

✔ Beautiful Variety – Wide range of colors and customizable patterns

✔ Low Maintenance – Easy to clean, no need for constant waxing

✔ Cost-Effective – More economical than traditional terrazzo or natural stone

✔ Versatile Applications, including:

- Wall panels

- Floor panels

- Window sills

- Skirting boards

- Partition boards

- Countertops

- Stair steps

- Pools & basins

- Coffee tables

- Rockery basins

🔹 High Density & Hardness – Resists peeling, dusting, and wear

🔹 Cost Savings – More affordable than natural decorative materials

🔹 Wider Selection – Greater choice in colors and finishes

🔹 Improved Surface Quality – Does not depend on waxing to maintain shine

Issue with Traditional Terrazzo:

Traditional terrazzo needs constant cleaning, polishing, and waxing. Over time, lack of proper care causes dull surfaces and reduced appeal. Colored cutting terrazzo overcomes these limitations with enhanced surface properties and long-lasting shine.

To restore or maintain the premium look of your terrazzo slab, follow this professional process:

Step 1: Surface Polishing

- Use advanced cutting equipment and polishing pads

- Grind and polish from coarse to fine grit for desired brightness

Step 2: Crystallization Process

- Apply crystal powder or refurbishing slurry

- Enhances wear resistance and surface hardness

- Strengthens the tile using modern crystallization technology

Step 3: Final Surface Finish

✔ Hardness equivalent to granite

✔ Gloss level exceeding 80 degrees

Step 4: Regular Maintenance

- Maintain monthly or quarterly based on foot traffic

- Helps preserve mirror-like shine for years

✅ Elegant Appearance – Reflects the beauty of marble

✅ Long-Term Durability – Comparable to high-end granite

✅ Low Lifecycle Cost – Minimal upkeep with maximum visual impact

Share