Custom Terrazzo Flooring

Custom Terrazzo Flooring

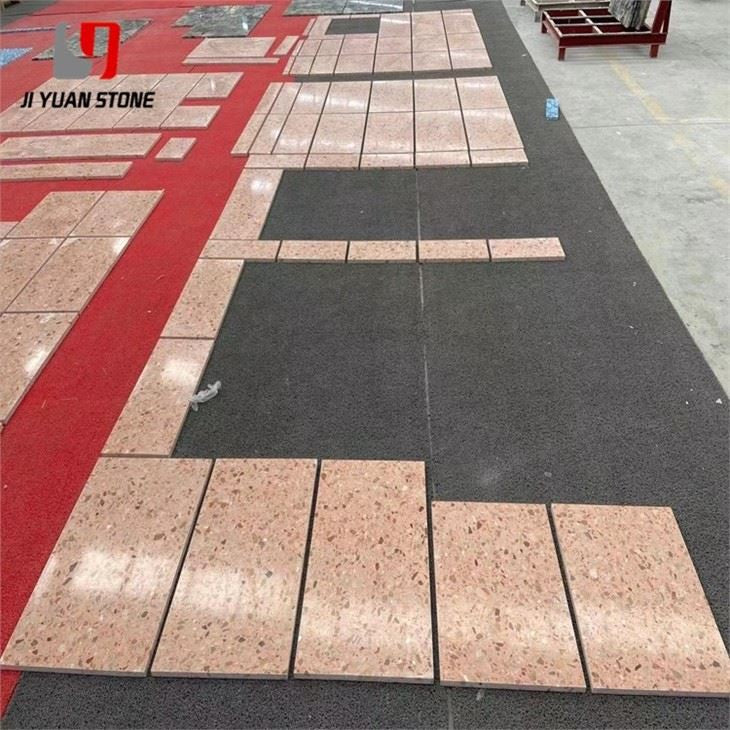

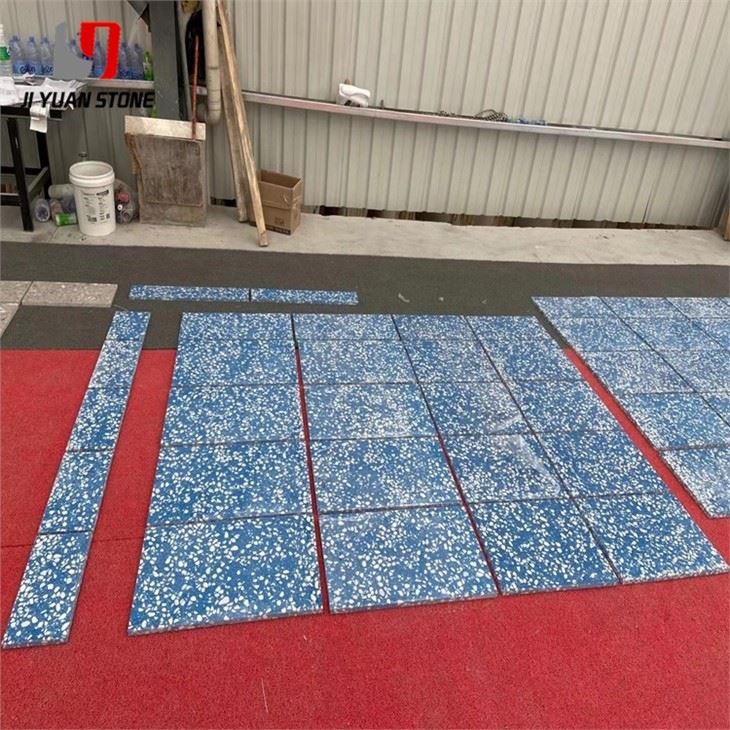

Custom Terrazzo Flooring – Precision-Crafted for Modern Design

Transform your space with our Custom Terrazzo Flooring. Made with expert craftsmanship and customizable designs, our terrazzo flooring offers long-lasting durability and unique aesthetic appeal. Elevate your interior design with this elegant and timeless flooring option.

| Feature | Details |

|---|---|

| Material | Terrazzo |

| Surface Finish | Polished,Honed |

| Slab standard size | 3200*1600mm/2700*1800mm/2400*1600mm/2400*1200mm |

| Tile standard size | 800*800mm/900*900mm |

| Available Thickness | 2cm/2.5cm/3cm or other thickness as customization. |

Our custom terrazzo flooring slabs offer unmatched versatility and elegance for residential, commercial, and architectural projects. Whether you're looking for large-size prefabricated terrazzo or polished custom slabs, our flooring solutions deliver strength, style, and seamless installation.

Custom terrazzo flooring is ideal for unique layouts and large-scale spaces that demand precision and durability. From luxury interiors to high-traffic public areas, our slabs meet the highest performance and aesthetic standards.

Large-Size Block Installation GuideWhen working with terrazzo panels exceeding 40cm in side length or installed at a height above 1 meter, special installation methods are required to ensure long-term structural integrity.

🔩 1) Drilling and Grooving TechniqueBefore installation:

Drilling Setup: Use a bench drill according to design specifications. Nail a wooden frame in place to align the drill directly with the slab’s upper edge.

Drill Points: On each side of the terrazzo slab, drill two holes at 1/4 of the slab’s width.

- Hole size: 5mm diameter, 12mm depth

- Hole distance: 8mm from the back surface (to the hole center)

🛠️ 2) Creating the “Elephant Nose” GrooveThis method applies to marble, prefabricated terrazzo, and polished custom terrazzo flooring with wider dimensions.

For larger slabs, increase the number of holes accordingly.

After drilling:

- Use a steel chisel to lightly carve a 5mm-deep groove into the hole wall that faces the back of the slab.

- The groove, combined with the drilled hole, creates an “elephant nose” shape, designed to embed copper wiring securely for mounting.

For particularly large slabs or when tying copper/galvanized lead wires at the bottom isn’t feasible:

Use a portable 4–5mm grinding wheel to cut grooves directly at the installation site.

Groove specs:

- Length: 3–4cm

- Depth: 12mm

- Location: Top and bottom of the slab at 1/4 of its height

This on-site method provides flexibility for installations where pre-drilling is not an option.

✅ Why Choose Our Custom Terrazzo Flooring?- High Strength & Durability – Designed to withstand heavy foot traffic and structural stress

- Custom Sizing – Cut and polished to meet your exact architectural needs

- Polished Finish – Enhances aesthetic appeal while improving surface protection

- Easy Integration – Compatible with other stone finishes and modern materials

- Professional Support – Backed by detailed installation guidance for perfect results

Our custom terrazzo flooring is ideal for:

- Airports and shopping malls

- Museums and galleries

- Hospitality & luxury interiors

- Hallways, lobbies, and public walkways

Share