Carrera Marble Vanity Top

Carrera Marble Vanity Top

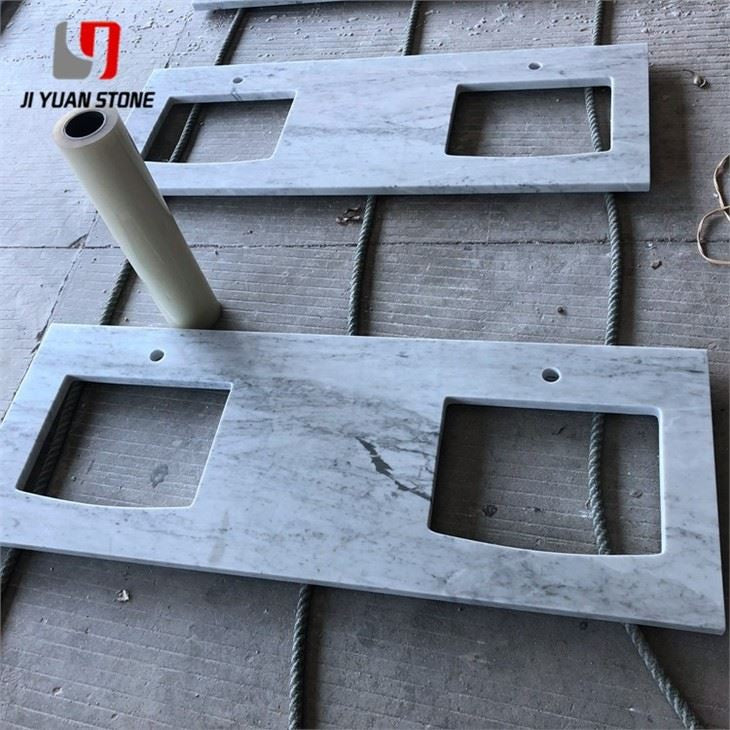

Carrera Marble Vanity Top – Timeless Elegance with Precision Craftsmanship

As a Carrera Marble expert, I can confidently assert that this vanity top is made with the finest Carrera Marble. This high-quality material provides a luxurious and elegant look to any bathroom. Its durability and resistance to scratches and stains make it a practical and long-lasting addition to your home. Upgrade your bathroom with this beautiful Carrera Marble Vanity Top.

Ji Yuan Stone Being a large and fast development stone enterprise in China, Ji Yuan Stone specializes in manufacturing and providing marble products, such as, Water-jet Medallion, Mosaic, Marble/Granite slabs and tiles, Fireplace, Basin, Stone stairs, Sculpture and Western Figures. Besides, Water-jet inlay is great demand in United States and Canada.

| Feature | Details |

|---|---|

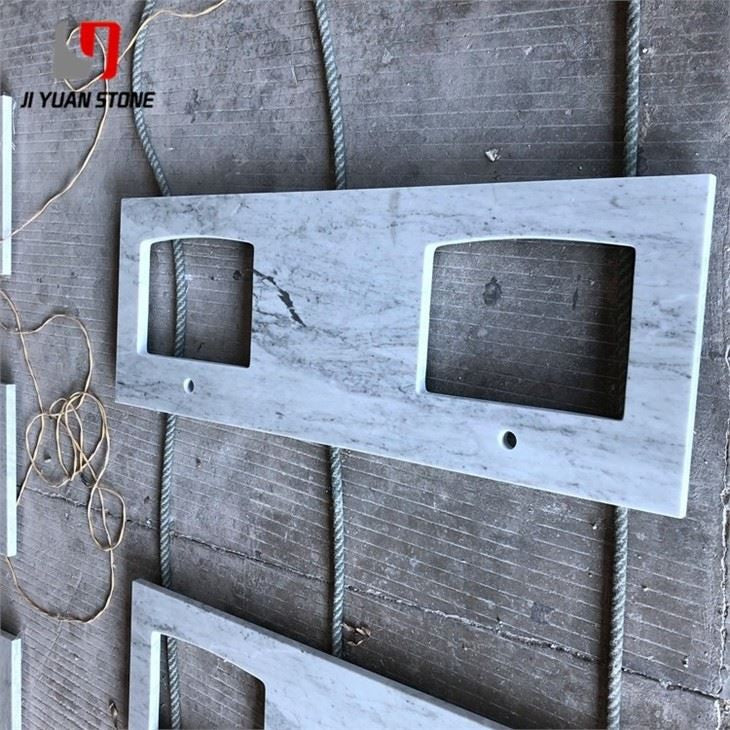

| Prefab Countertop Size: | 96"/98"/108"/110"x26"/25.5", Or Customized |

| Prefab Vanity Top Size: | 25"/31"/37/43"/49''/61''/73''x26"/25.5", Or Customized |

| Prefab Island Size: | 72"x36", 96"x36", 96"x38", 96"x40", Or Customized |

| Prefab Backspalsh Size: | 2'', 4'', 6'', Or Customized |

| Standard Thickness: | 2cm (3/4''), 3cm(1 1/4''), 20+20mm laminated, 30+20mm laminated, etc |

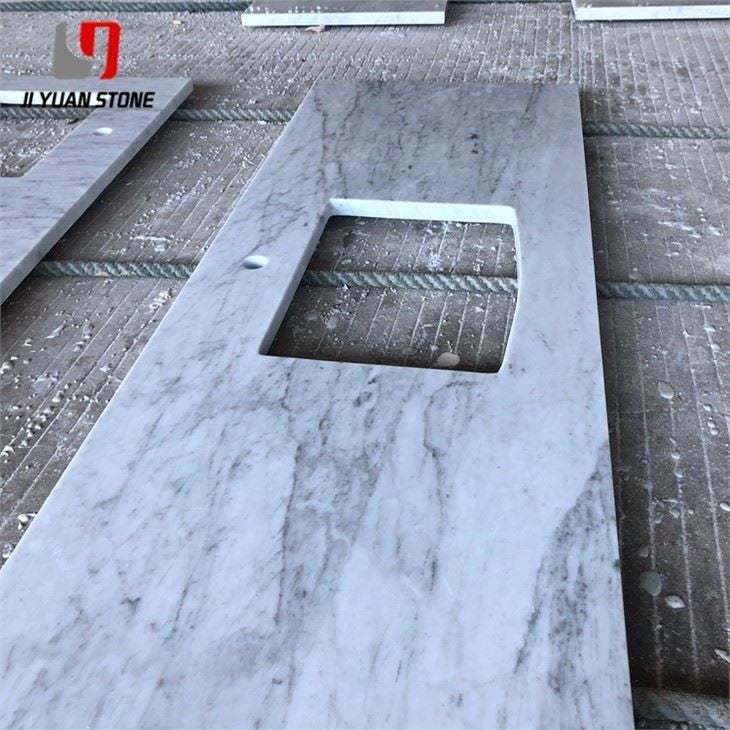

A Carrera marble vanity top brings unmatched beauty and sophistication to bathrooms, kitchens, and luxury interiors. Known for its soft white base with elegant gray veining, Carrera marble is a favorite among homeowners, designers, and architects for its natural charm and versatility.

To ensure durability and aesthetics, every Carrera marble countertop undergoes strict cutting, edge processing, and polishing procedures for a flawless finish.

Precision Cutting & Quality Standards

During fabrication, it is necessary to ensure that the geometric dimensions, angle dimensions, and diagonal dimensions of the finished Carrera marble vanity top are accurate.

- No edge chipping or corner drop is allowed.

- If bonding is required at the back, the edges and corners must remain intact to support proper edge processing.

Edge Processing & Custom Profiles

Edge processing enhances both the appearance and strength of the vanity top. The Crema Marfil vanity top edges are shaped using profiling machines to meet specific order requirements.

Available Edge Profiles:

✔ Eased

✔ Full Bull-nose

✔ Half Bull-nose

✔ OG

✔ Laminated Full Bull-nose

✔ Laminated OG

Equipment Used: Automatic edge grinding & chamfering machines, profile milling machines, and manual polishing tools.

Thickening & Bonding Process

For thicker edge designs:

1 . A small cutting machine smooths the area to be thickened.

2 . The bonding surface is roughed for stronger adhesion.

3 . Edges are glued and clamped firmly.

4 . Ideal bonding gaps are maintained at 0.1–0.2 mm for maximum stability.

5 . Once the glue is fully dry, the surface is processed and polished.

Advanced factories use automated profiling edging machines for precision, while general factories rely on manual cutting and polishing.

Features of Carrera Marble Vanity Tops

✔ Natural elegance with unique gray veining

✔ Wide range of edge profile customization

✔ Precision-cut for accurate dimensions

✔ Durable, long-lasting, and heat resistant

✔ Available in custom sizes and finishes

Applications

- Bathroom Vanity Tops – Enhances luxury bathrooms with elegance.

- Kitchen Countertops – Adds timeless sophistication.

- Custom Projects – Hotels, commercial centers, and premium residential spaces.

Conclusion

A Carrera marble vanity top is more than just a countertop – it’s a symbol of refined taste, precision craftsmanship, and lasting beauty. With custom edge profiles, accurate cutting, and polished finishes, these marble tops are perfect for those who value both style and durability in their living spaces.

Share