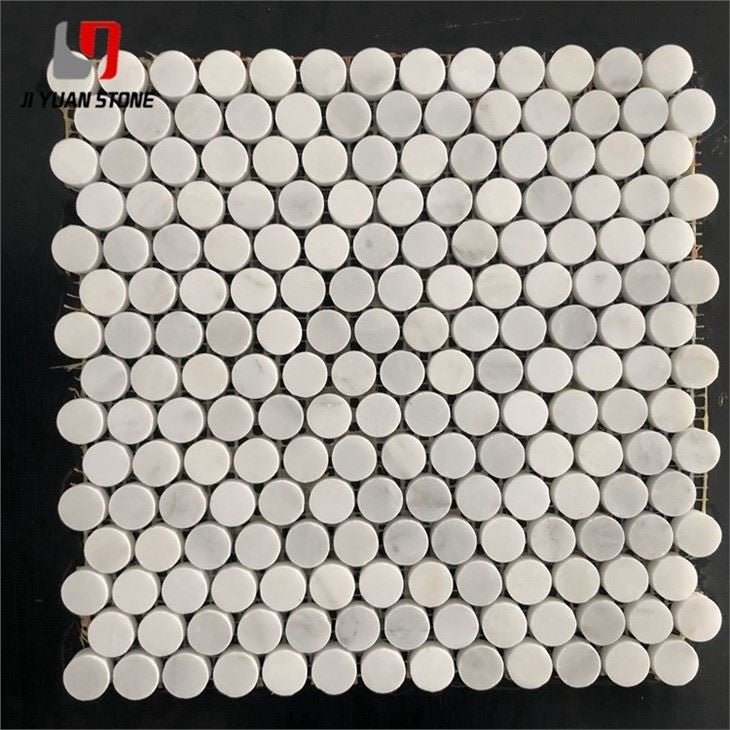

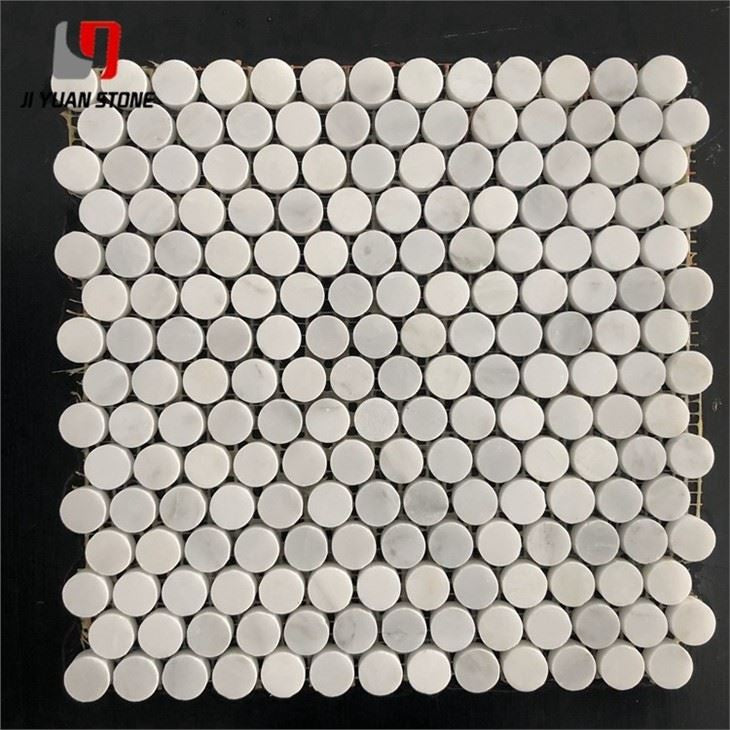

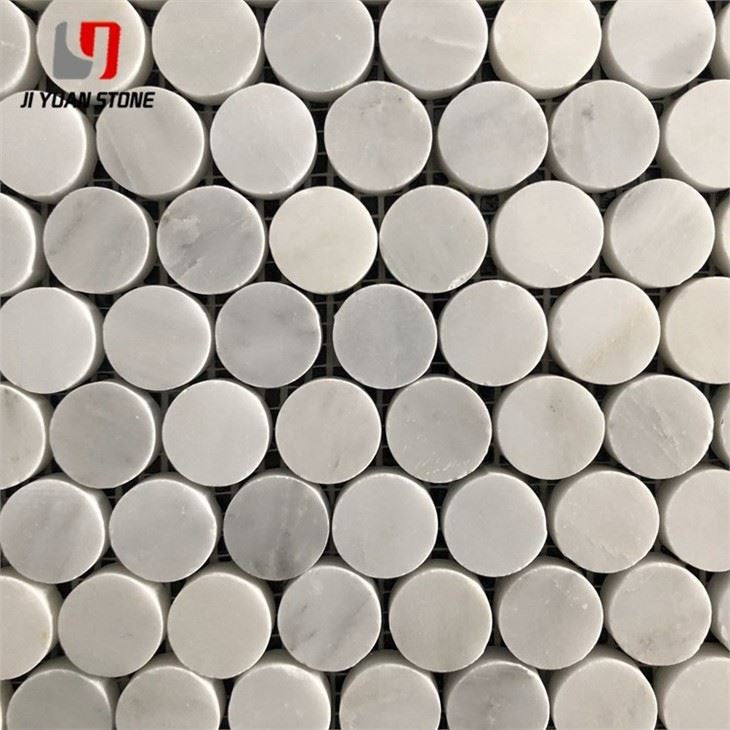

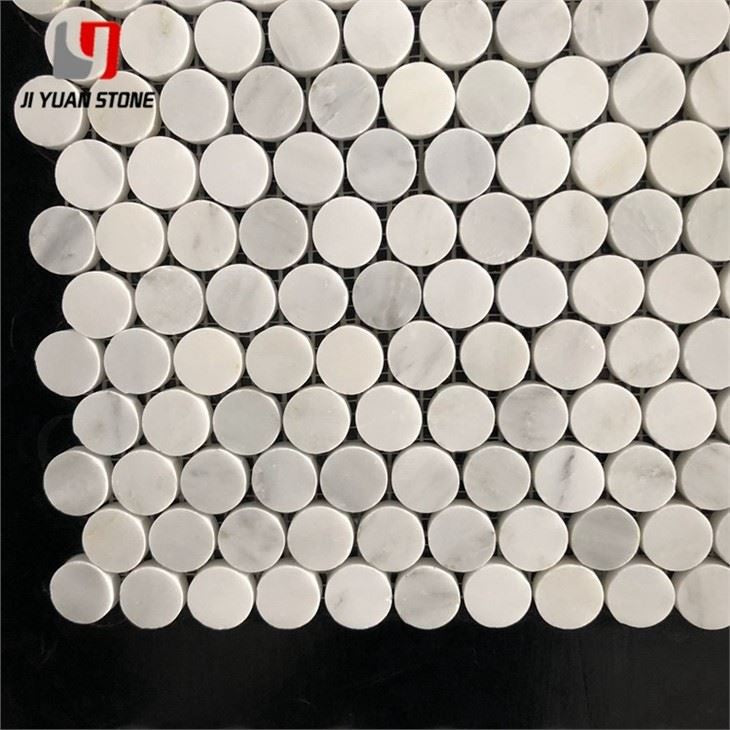

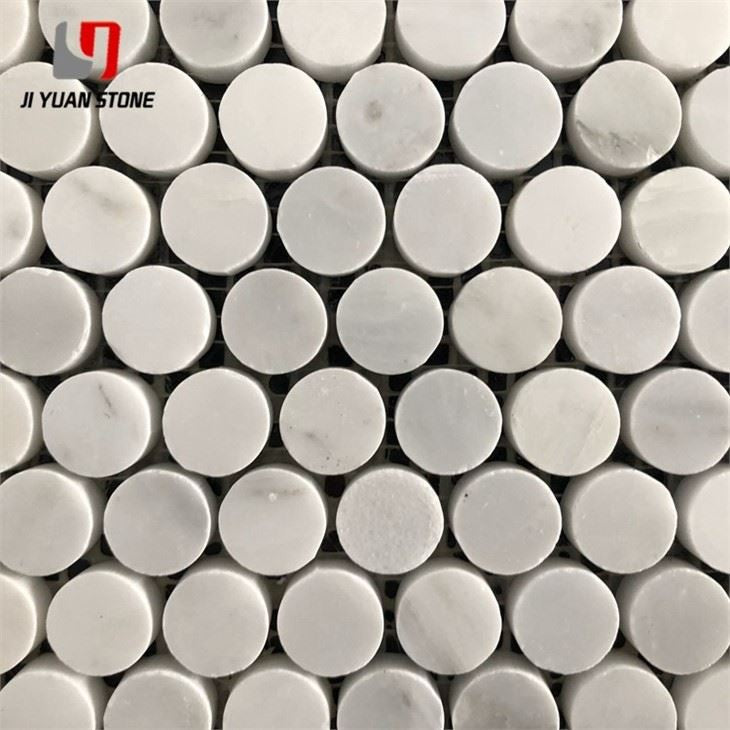

Carrara Penny Round Tiles

Carrara Penny Round Tiles

Elevate the look of your space with Carrara Penny Round Tiles. Made from high quality Carrara marble, these stunning round tiles add a touch of luxury to any room. The unique shape and elegant design bring a timeless and sophisticated feel to your home. Expand your design possibilities with Carrara Penny Round Tiles.

| Feature | Details |

|---|---|

| Material | Natural Marble Stone,Travertine,Limestone |

| Colour | As pictures show or customized |

| Shape | Square, Basketweave, Mini brick, Modern brick, Herringbone, Subway, Hexagon, Octagon, Mixed, Grand fan, Penny round, Hand clipped, Tesserae, Random strip, River rocks, 3D cambered, Pinwheel, Rhomboid, Bubble round, Circle bubble, Stacked, etc... |

| MOQ | Unrestricted |

| Regular size | 305 x 305mm, cut-to-size, or according to customer's requirement |

| Thickness | 7mm,10mm |

| Color | Black, grey, yellow, rusty, white, pink, multicolor etc. |

| Finishing | Honed ;split :mushroom ;picked ;stick with cement or glue |

| Package | Carton box and wooden crate,plywood pallet or plywood crate |

| Delivery time | Sample-- abt 2-5days Order ---- abt 10-20days after the deposit. |

| Payment | T/T;30%deposit and 70%blance against copy of B/L; or L/C at sight. |

| Loading port | Guangzhou/Xiamen/Shenzhen/Foshan |

| Min order | 50 square meters |

| Export Market | European, north America, Australia and middle east |

Arc Board Parquet Processing

Introduction

As a new innovation in stone products, arc panel Carrara penny round tiles have gradually gained popularity in construction and interior decoration. These tiles are an evolution of flat panel mosaics, adapted for curved surfaces. However, arc board mosaics are significantly more complex and challenging to process compared to flat mosaics due to their curved nature.

Processing Techniques

The processing of arc board parquet involves three main methods:

- Waterjet machine processing

- Machining center processing

- Manual processing

Among these, waterjet machine processing is a widely used technique. However, due to the limitations of most three-axis waterjet machines, they can only process arc board Carrara penny round tiles with a radius of approximately 500mm.

Waterjet Machine Processing for Arc Board Mosaic

1. Technical Requirements

- The rotation radius of the device must be as close as possible to the radius of the arc board mosaic.

- An acceptable variation is R ±50mm, ensuring a consistent cutting radius for precision.

2. Processing Steps

- Prepare the pattern drawing and programming based on the production processing sheet.

- Position the arc plate correctly on the specialized workbench of the waterjet machine, following the numbering direction of the layout.

- Set the tool and processing zero point to ensure accurate cutting.

- Simulate the processing procedures before initiating the actual cut.

- Proceed with the cutting process according to the programmed instructions.

Since most arc board mosaics have an arch height exceeding 120mm, the standard waterjet machining depth is often insufficient. To address this, the workbench must be lifted during processing to accommodate the required cutting depth.

3. Arc Board Carrara Penny Round Tiles Processing Procedure

- Step 1: Rotate one side of the arc plate to a horizontal position before processing.

- Step 2: As the Y-axis cutting width increases, manually adjust the handwheel to keep the waterjet cutter head aligned with the arc plate surface.

- Step 3: Avoid any Y-axis movement of the cutter head, as this can impact cutting accuracy.

This step requires special attention, as it is a critical phase in the arc board parquet processing. Precise execution ensures a high-quality finished product with consistent design and smooth curves.

Share