1

/

of

9

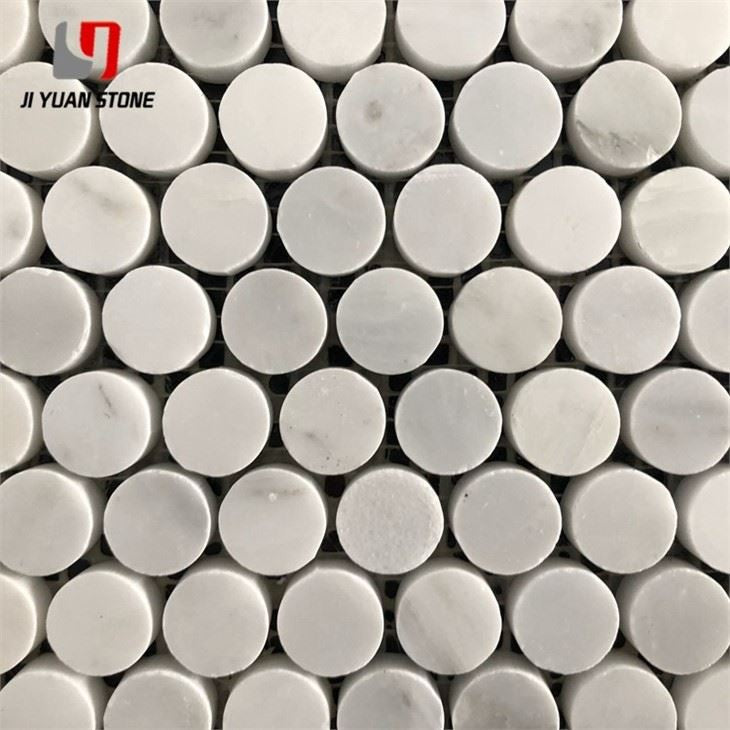

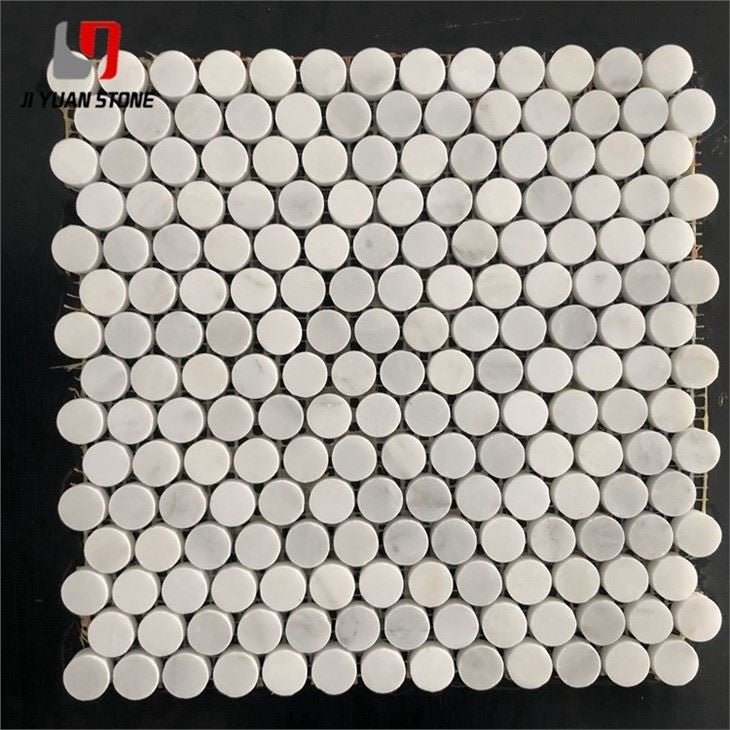

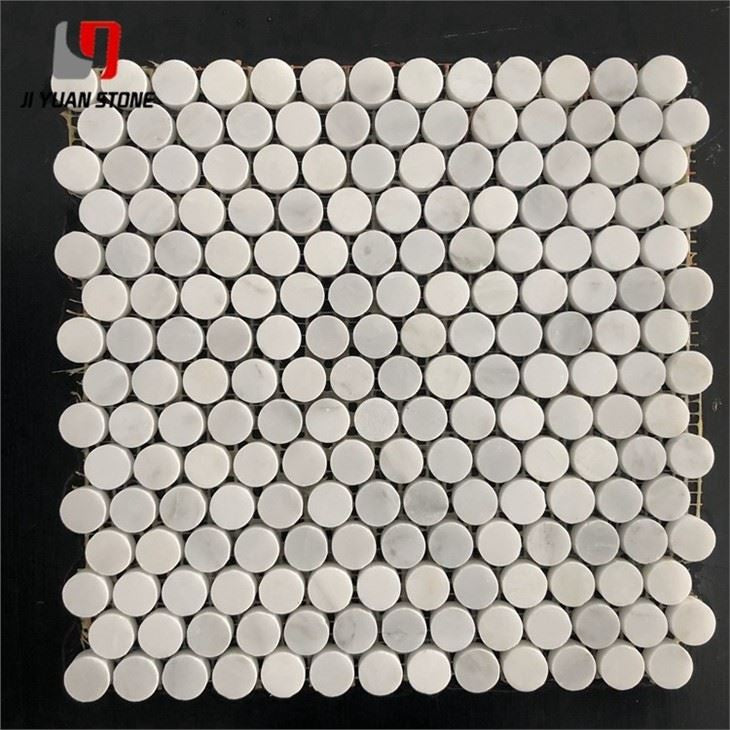

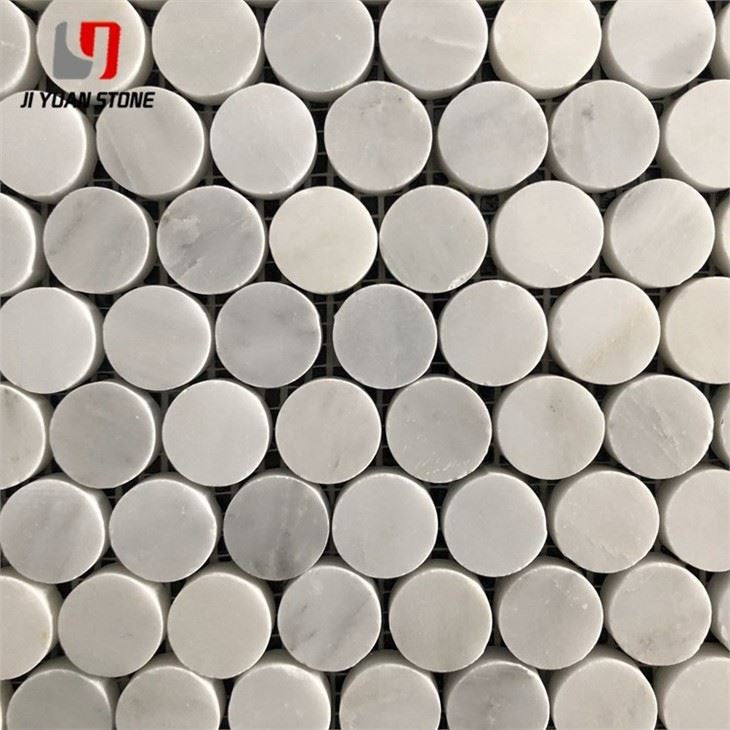

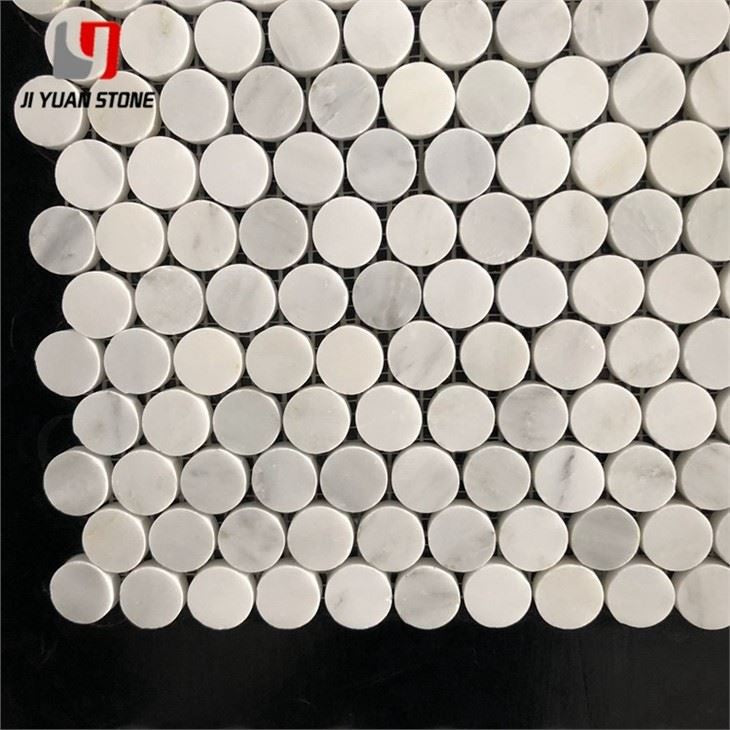

Carrara Penny Round

Carrara Penny Round

Introducing Carrara Penny Round, the perfect addition to your home or commercial space. With its classic round shape and iconic Carrara marble material, this tile offers a timeless and elegant look. Enjoy the benefits of high quality, durable construction and elevate any room with a touch of sophistication.

| Feature | Details |

|---|---|

| Material | Natural Marble Stone,Travertine,Limestone |

| Colour | As pictures show or customized |

| Shape | Square, Basketweave, Mini brick, Modern brick, Herringbone, Subway, Hexagon, Octagon, Mixed, Grand fan, Penny round, Hand clipped, Tesserae, Random strip, River rocks, 3D cambered, Pinwheel, Rhomboid, Bubble round, Circle bubble, Stacked, etc... |

| MOQ | Unrestricted |

| Regular size | 305 x 305mm, cut-to-size, or according to customer's requirement |

| Thickness | 7mm,10mm |

| Color | Black, grey, yellow, rusty, white, pink, multicolor etc. |

| Finishing | Honed ;split :mushroom ;picked ;stick with cement or glue |

| Package | Carton box and wooden crate,plywood pallet or plywood crate |

| Delivery time | Sample-- abt 2-5days Order ---- abt 10-20days after the deposit. |

| Payment | T/T;30%deposit and 70%blance against copy of B/L; or L/C at sight. |

| Loading port | Guangzhou/Xiamen/Shenzhen/Foshan |

| Min order | 50 square meters |

| Export Market | European, north America, Australia and middle east |

Processing Steps for Carrara Penny Round Parquet

1. Material Selection

- Choose materials according to the standard of flat parquet.

2. Material Preparation

- For unconventional materials, use a circular saw or other cutting equipment.

- Ensure smooth surfaces are polished before further processing.

3. Cutting the Base Plate

- Cut the bottom plate according to the size specifications on the production processing sheet.

- If the bottom plate has a special shape, use a water jet machine for precision cutting.

4. Cutting Parquet Pieces

- Program the water jet machine to cut the parquet pieces based on the provided graphics in the production sheet.

5. Typesetting and Toning

- Arrange the cut pieces according to the pattern design.

- Eliminate defective pieces and adjust the color tones to ensure uniformity within the same material.

6. Grinding and Assembling

- The pieces cut by the water jet machine may have burrs.

- Use a hand grinder to trim and smooth the edges before assembling.

7. Side Grinding and Polishing

- Since three-dimensional Carrara penny rounds protrude from the bottom surface, all sides must be polished, chamfered, and edged for a refined finish.

8. Rough Grinding of the Bottom Plate

- The bottom plate is a light panel and must be roughened before bonding the pieces.

- This enhances adhesion between the pieces and the bottom plate.

9. Positioning and Bonding

-

Positioning Methods:

- Use drawn guidelines or

- Utilize an engraving machine to mill the glued area 1mm deep according to the pattern.

- Apply dry-hanging glue or Hercules glue to the designated glued area.

- Place the pieces in their corresponding positions, moving them slightly to ensure even glue distribution.

- Before the glue dries, remove any excess to maintain surface quality.

10. Surface Glue Treatment

- Use glue matching the board’s color to fill any gaps and enhance seams, edges, and corners for a flawless finish.

Share