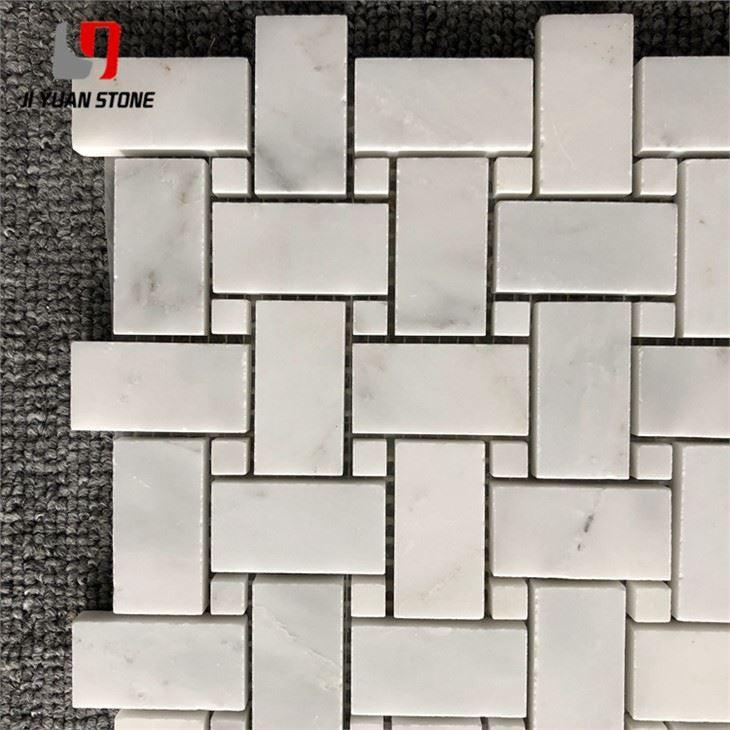

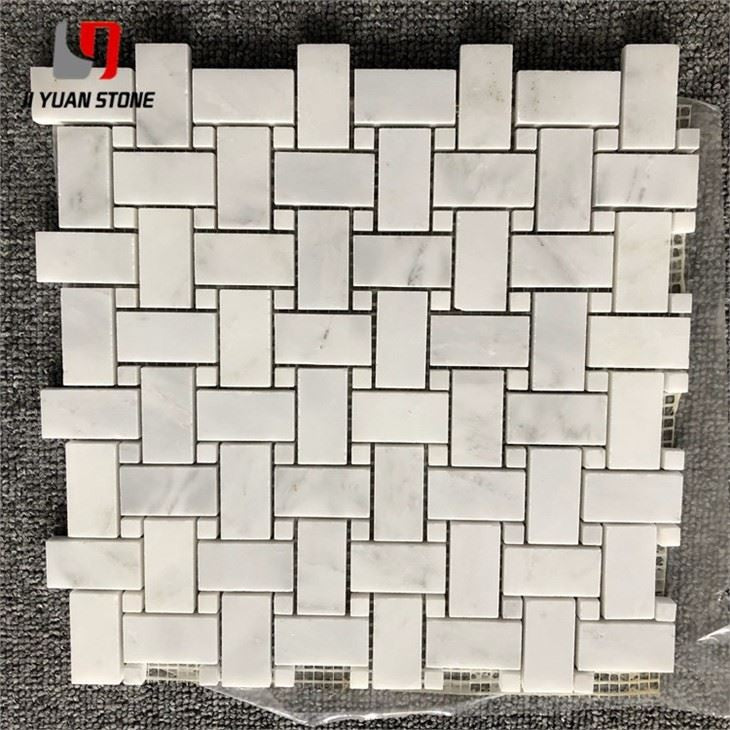

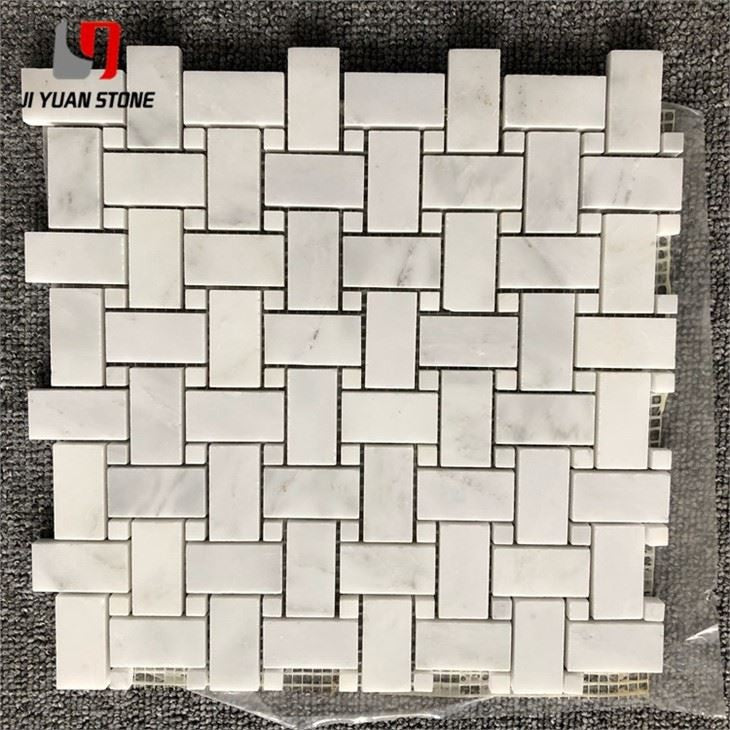

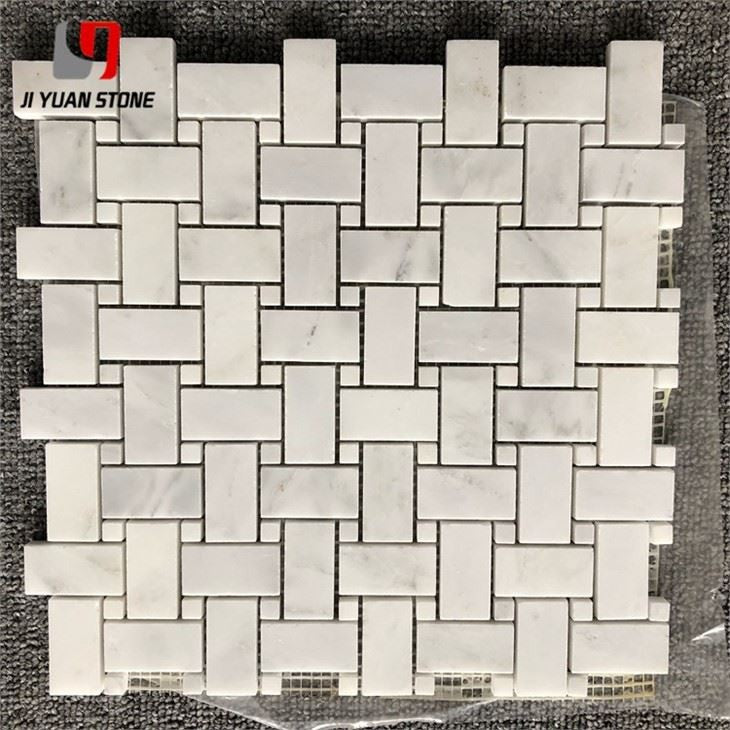

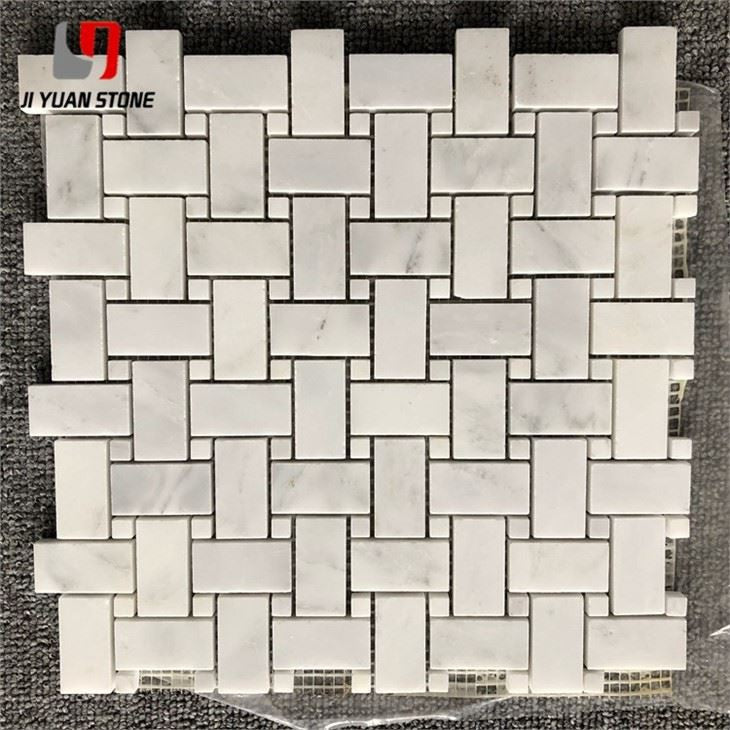

Carrara Bianco penny round mosaic is a high-quality natural marble mosaic known for its elegance, durability, and refined aesthetic appeal. Ideal for wall and interior design, this mosaic combines timeless beauty with practical construction techniques for both residential and commercial spaces.

Dry Pendant Point Hanging (Floating Pieces) Guide

1. Floating Pieces Installation

- Finishing Surface: Cement base to finished mosaic surface ≥90mm

- Auxiliary Materials: Stainless steel expansion screws, stainless steel dry hanging floats, marble glue, dry hanging AB glue

- Construction Conditions: Suitable for concrete walls and solid brick walls. Recommended height not to exceed 3000mm

Note: Horizontal seam positions follow a groove-drawing process. Floating parts should be hung on the upper and lower sides of the flat seam during construction.

2. Internal Welded Steel Structure (Butterfly Pieces)

- Finishing Surface: Cement base to finished mosaic surface ≥90mm

- Auxiliary Materials: Stainless steel expansion screws, stainless steel dry hanging floats, marble glue, dry hanging AB glue, ∠50 angle steel, main keel, secondary keel

- Construction Conditions: Suitable for hollow bricks and foam bricks. For heights exceeding 3000mm, a steel frame structure is recommended

Note: Horizontal seam positions follow a slotting process. For butterfly pendants, the mosaic must be bonded to the back of the board to increase thickness, easing slotting installation.

3. Internal Welding Dry Hanging Structure (Floating Parts)

- Finishing Surface: Cement base to finished mosaic surface ≥90mm

- Auxiliary Materials: Stainless steel expansion screws, stainless steel dry hanging floats, marble glue, dry hanging AB glue, ∠50 angle steel, main keel, secondary keel

- Construction Conditions: Suitable for hollow bricks and foam bricks. For heights exceeding 3000mm, a steel frame structure is recommended

Note: Horizontal seam positions follow a groove-drawing process. Floating parts should be hung on the upper and lower sides of the flat seam.

Carrara Bianco penny round mosaic is perfect for creating visually appealing feature walls, backsplashes, and interior accents. Its combination of natural elegance and structured installation options ensures both durability and sophisticated design for any modern space.