1

/

of

9

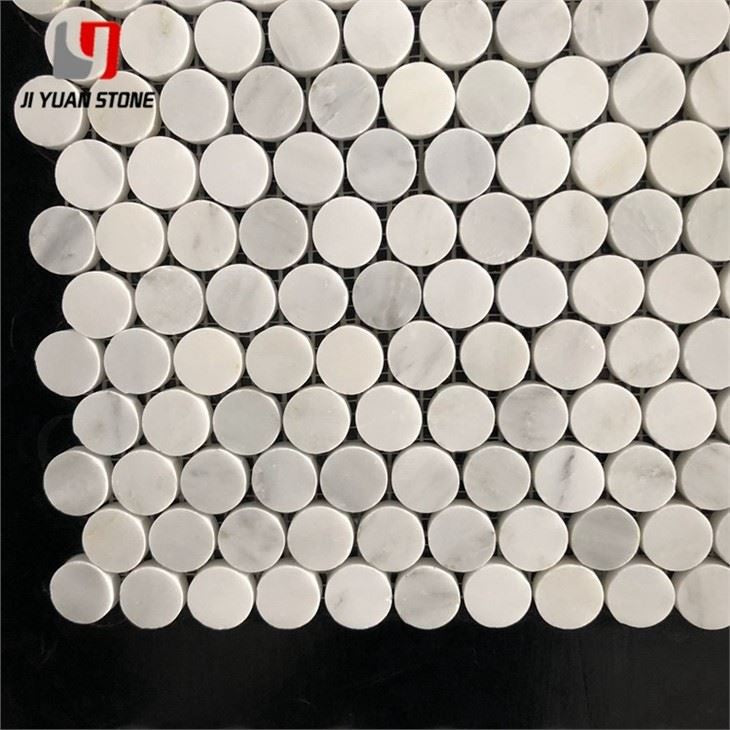

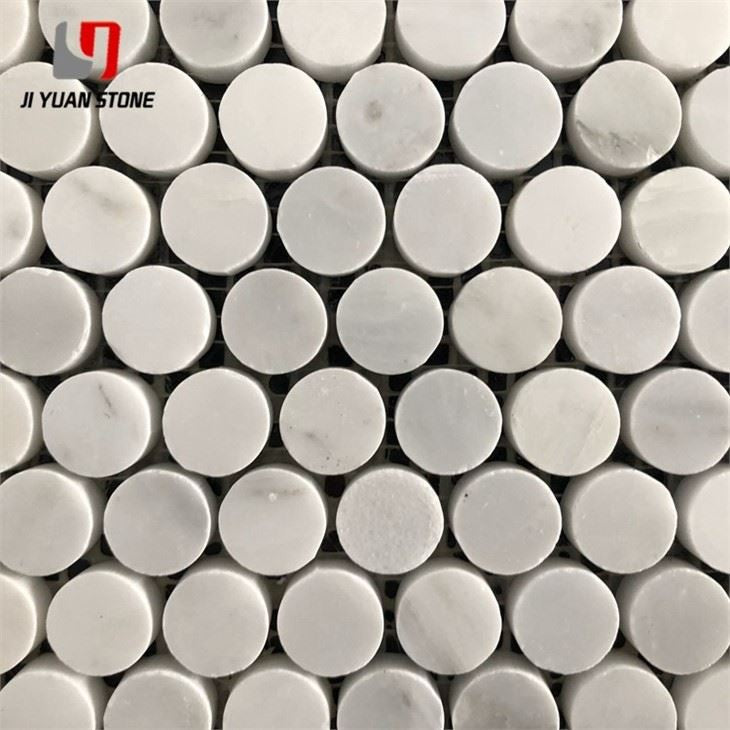

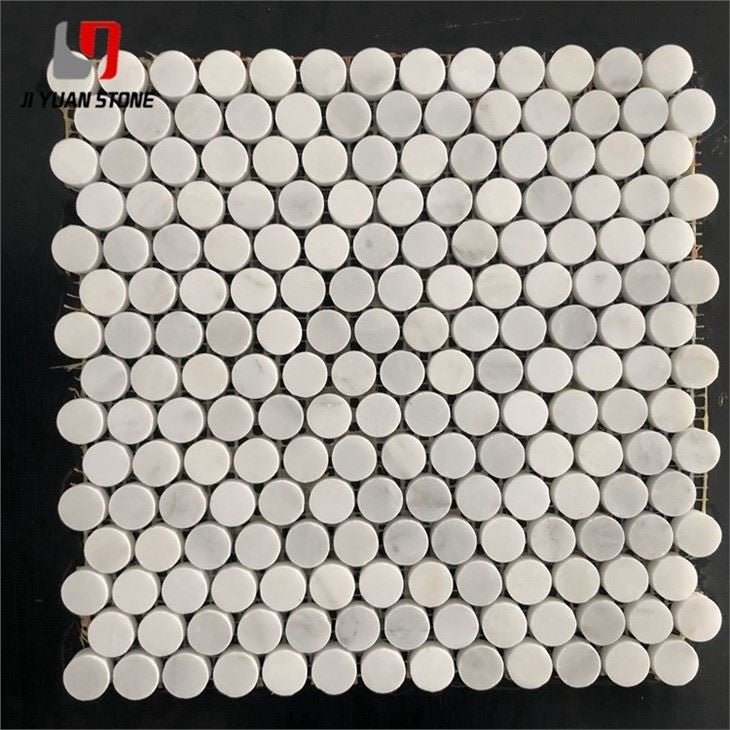

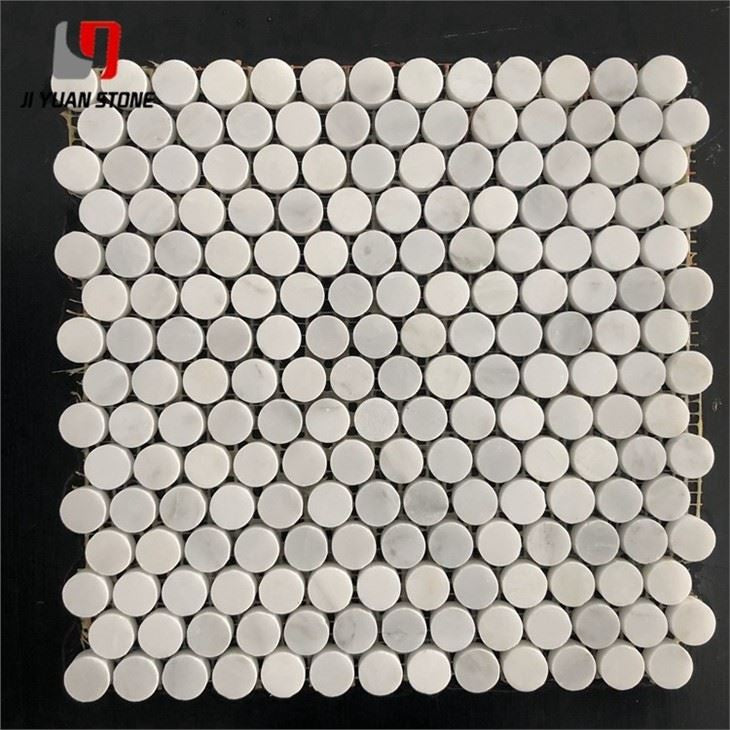

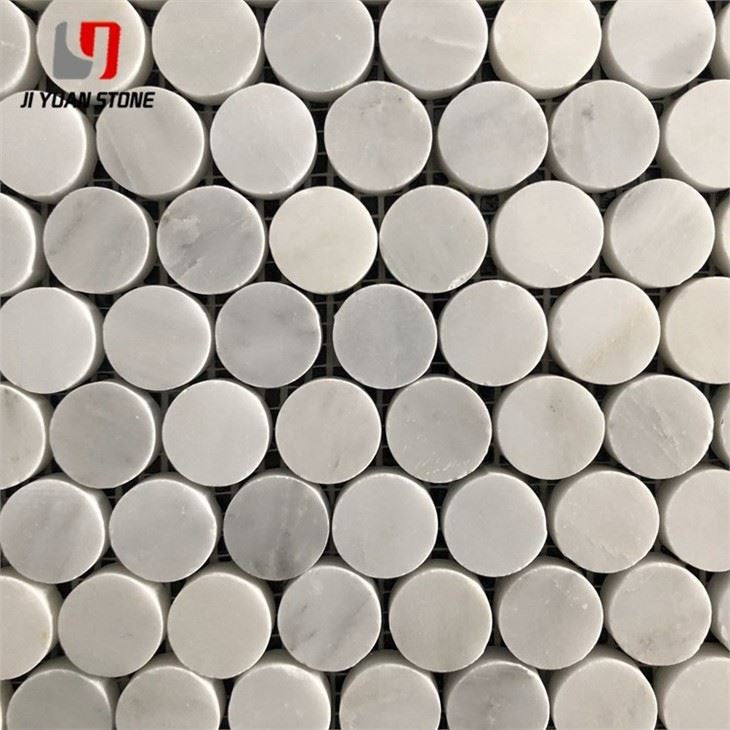

Calacatta Penny Round

Calacatta Penny Round

As a product expert in the tile industry, our Calacatta Penny Round features a stunning design of marble-like veining on a round penny-shaped tile. Made from high-quality materials, it offers a timeless look for any space. Elevate your interior with our Calacatta Penny Round.

| Feature | Details |

|---|---|

| Material | Natural Marble Stone,Travertine,Limestone |

| Colour | As pictures show or customized |

| Shape | Square, Basketweave, Mini brick, Modern brick, Herringbone, Subway, Hexagon, Octagon, Mixed, Grand fan, Penny round, Hand clipped, Tesserae, Random strip, River rocks, 3D cambered, Pinwheel, Rhomboid, Bubble round, Circle bubble, Stacked, etc... |

| MOQ | Unrestricted |

| Regular size | 305 x 305mm, cut-to-size, or according to customer's requirement |

| Thickness | 7mm,10mm |

| Color | Black, grey, yellow, rusty, white, pink, multicolor etc. |

| Finishing | Honed ;split :mushroom ;picked ;stick with cement or glue |

| Package | Carton box and wooden crate,plywood pallet or plywood crate |

| Delivery time | Sample-- abt 2-5days Order ---- abt 10-20days after the deposit. |

| Payment | T/T;30%deposit and 70%blance against copy of B/L; or L/C at sight. |

| Loading port | Guangzhou/Xiamen/Shenzhen/Foshan |

| Min order | 50 square meters |

| Export Market | European, north America, Australia and middle east |

Processing Steps for Copying Machine Modeling Slotted Plate

1. Profiling Machine Shaping

- The profiling machine shapes the grooved surface of the plate according to the drawings in the production processing sheet.

- The grooved plate is then polished and refined using a grinder.

2. Engraving Machine Modeling

- The engraving machine carves the grooved plate according to the drawings in the production sheet.

- Minimum engraving depth: 10mm.

3. Grinding the Pieces and the Grooved Board

- The waterjet-cut pieces are compared with the engraved grooved plate.

- Both are polished to ensure their contours align within a 1mm deviation.

- Burrs are removed, and R2 small round edges are polished on the sides.

4. Polishing Individual Pieces

- The sides and round edges (R2) of each piece are carefully polished.

5. Toning and Test Assembly

- Pieces are arranged according to the Calacatta penny round patterns in the production sheet.

- Color matching is adjusted to ensure uniformity within the same puzzle.

6. Gluing and Assembling

- Polished pieces are glued into a solid jigsaw, following the pattern specifications.

- The pieces are sunk 10mm and secured with dry-hanging glue.

-

Height Adjustments:

- 20mm plate → 10mm higher than the trough plate

- 16mm plate → 6mm higher than the trough plate

- 30mm plate → 20mm higher than the trough plate

7. Final Assembly and Inspection

- Each component of the parquet is assembled following the assembly drawing.

-

Quality inspection:

- Color consistency

- Surface quality

- Assembling gap

- Bonding firmness

- Once approved, numbering is applied:

- The same number is written on the back of each piece using an oil pen.

8. Three-Dimensional Calacatta Penny Round Assembly

-

-

Surface-Adhesive Three-Dimensional Mosaic:

- A mosaic where pieces are glued directly onto a base plate.

- Unlike flat three-dimensional mosaics, the pieces protrude at different heights.

- This staggered elevation creates a three-dimensional Calacatta penny round effect.

-

Surface-Adhesive Three-Dimensional Mosaic:

Share