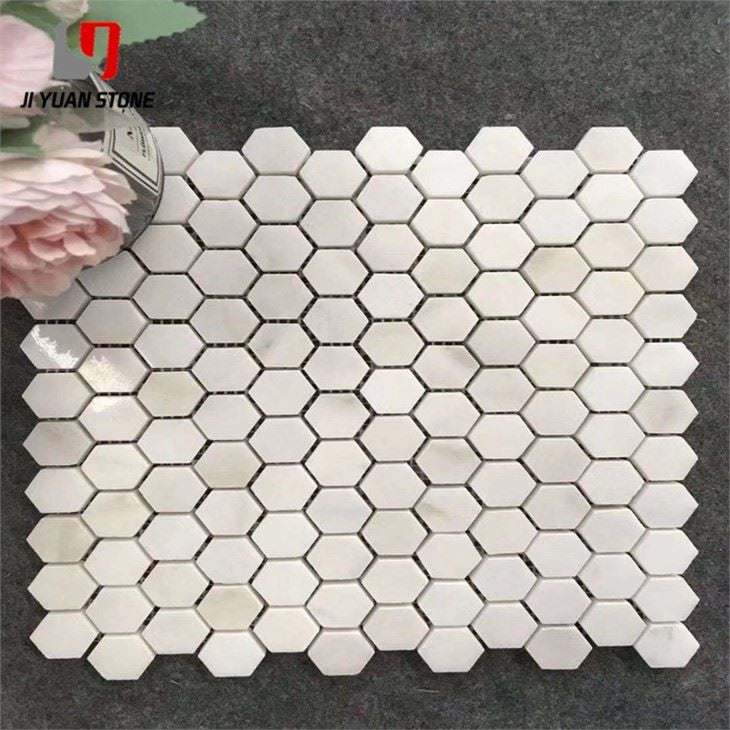

The Calacatta Mosaic Tile is synonymous with luxury, sophistication, and visual harmony. Its natural veining, bright white background, and high-quality finish make it perfect for both residential and commercial spaces. Proper planning and execution are essential to achieve a flawless paving result.

Unlocking in All Directions: A Guide to Typesetting Landscape Calacatta Mosaic Tile PavingUnlock the Secrets of Perfect Paving Today

Paving with Calacatta mosaic tiles requires technical expertise and careful planning. Follow these essential steps to ensure a seamless, consistent, and aesthetically stunning finish.

When planning a paving project, focus on:

- Material Selection

- Model Making

- Layout Lofting

- Bonding Layer Control

- Seam Width Control

- Jointing Technique

- Finished Product Protection

- Important Node Layout Control

1. Sampling

Use tiles with high color saturation to maintain uniformity and consistency with the design tone.

2. Material Selection

Select high-quality materials before they enter the site. For strict quality requirements:

- Assign specialists to source materials directly from manufacturers.

- Establish exclusive supply channels.

- Purchase from the same batch to ensure uniformity.

3. Processing

Maintain strict quality control over cutting. Reject any tiles with low quality or excessive color variation.

4. Paving and Pasting

On-site screening by workers identifies tiles with defects or inconsistent colors. Minimize variation for a uniform, aesthetically pleasing finish.

5. Sample Test Paving

Conduct test paving to ensure all materials blend harmoniously. Define:

- Seam width between tiles

- Groove depth

- Jointing agent color

- Final aesthetic effect

Retain paving samples for reference by construction teams to maintain process consistency and quality.

By adhering to these guidelines, your Calacatta mosaic tile paving project will be seamless, visually consistent, and a hallmark of luxury and refinement—perfectly enhancing any interior or exterior space.