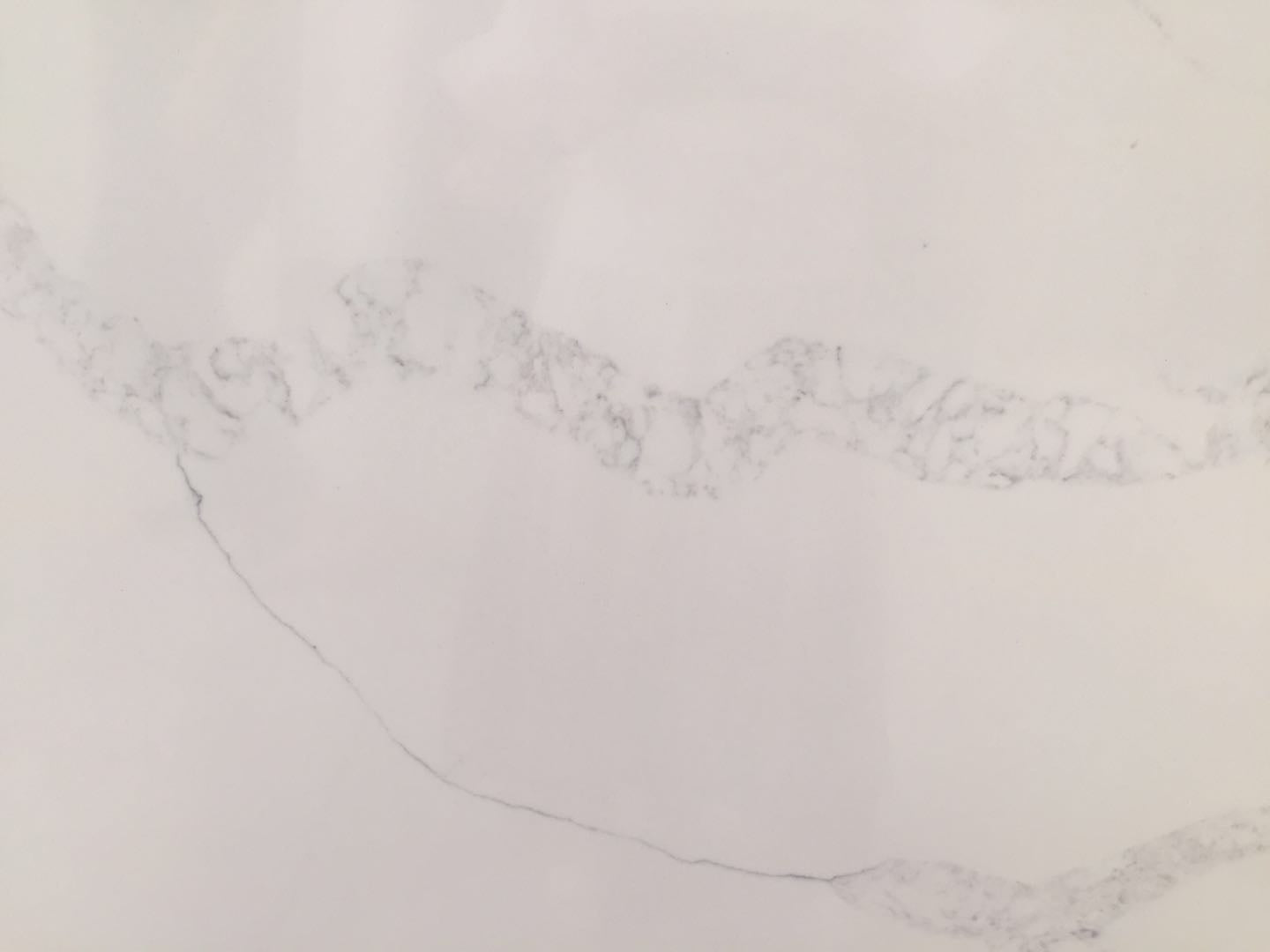

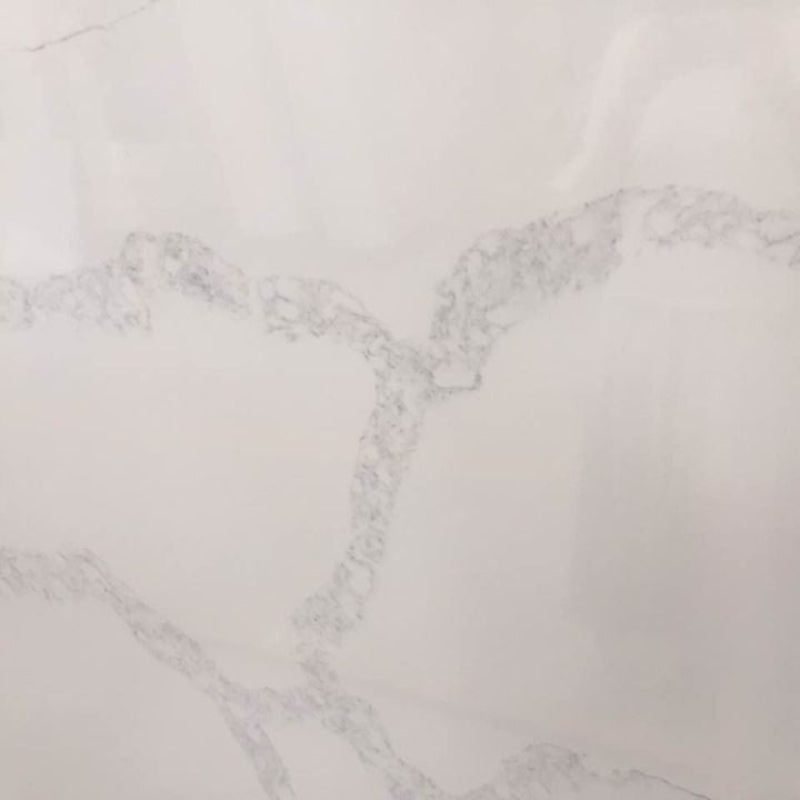

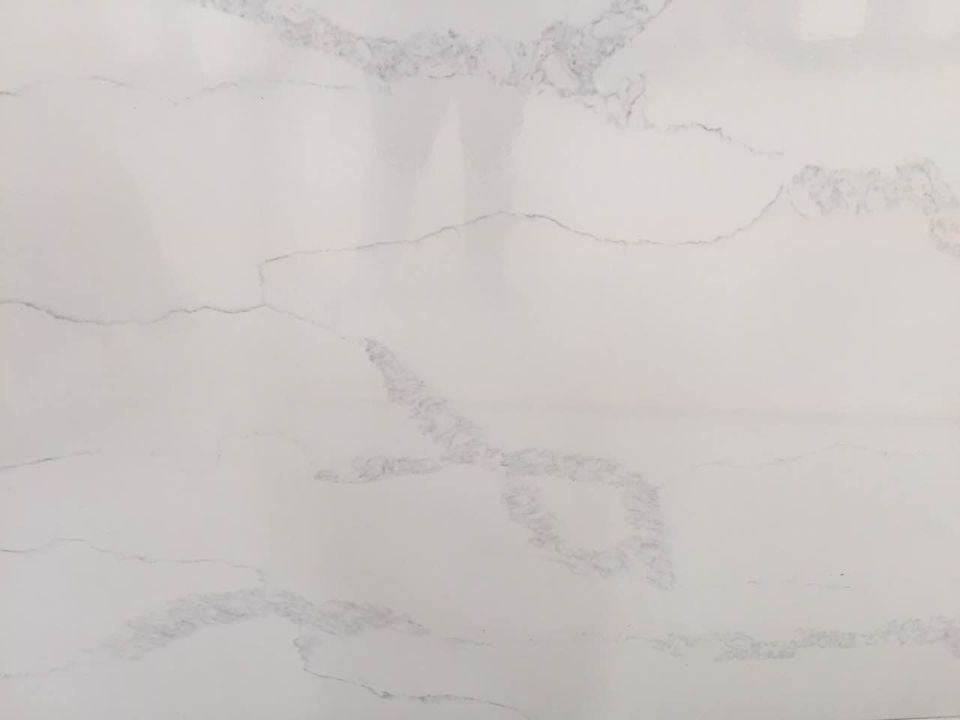

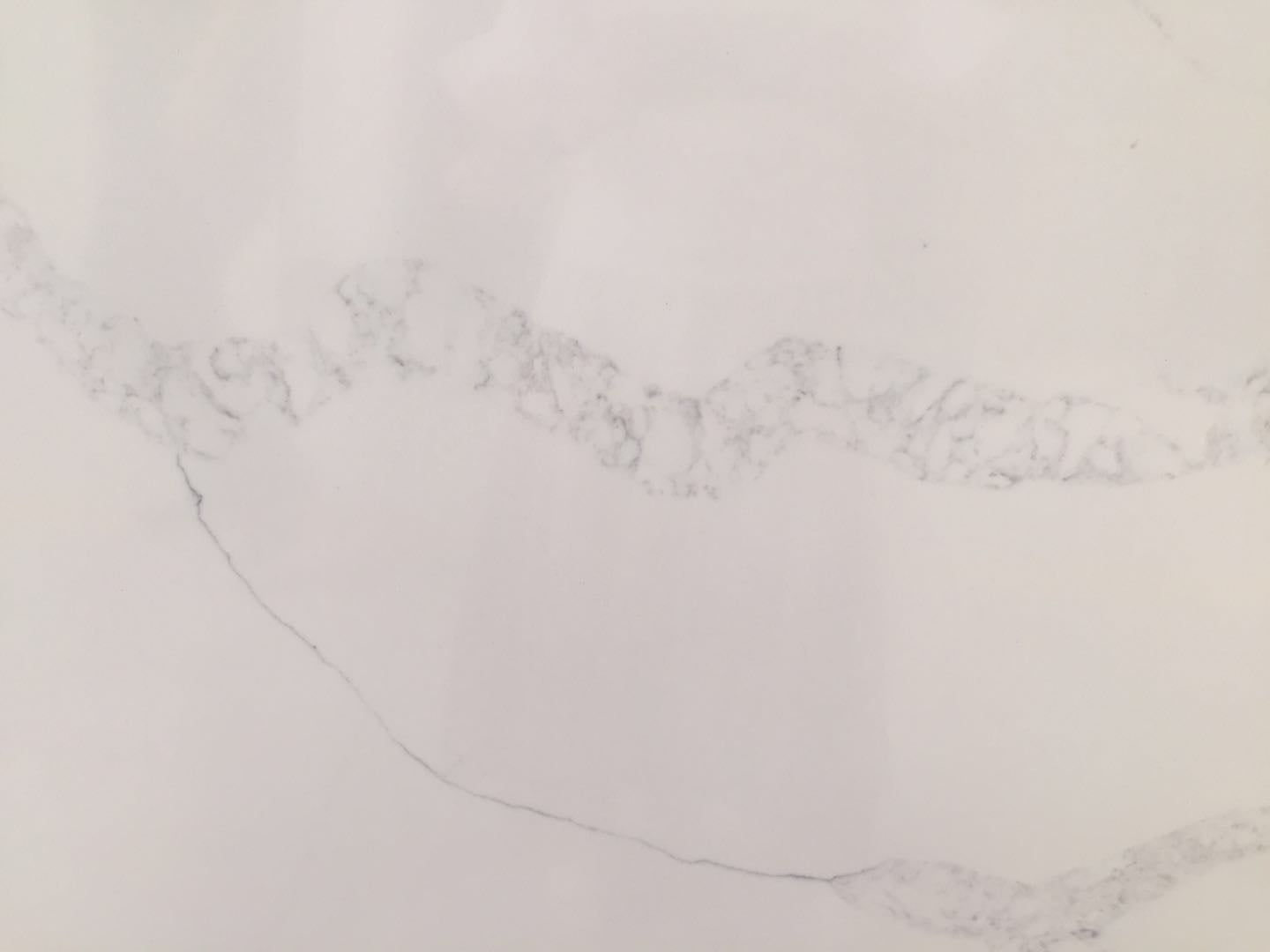

Calacatta Engineered Stone

Calacatta Engineered Stone

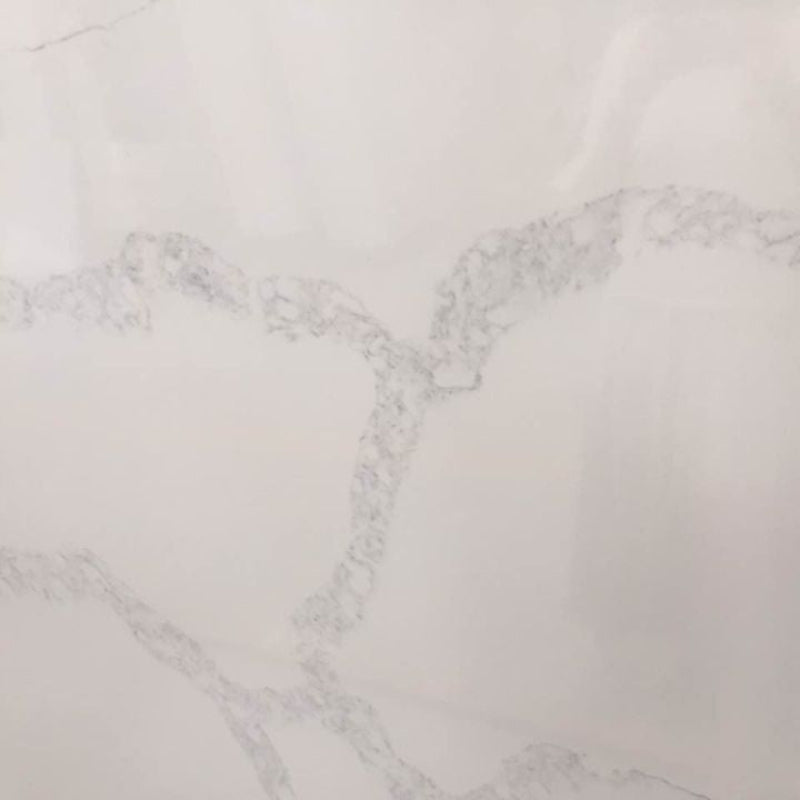

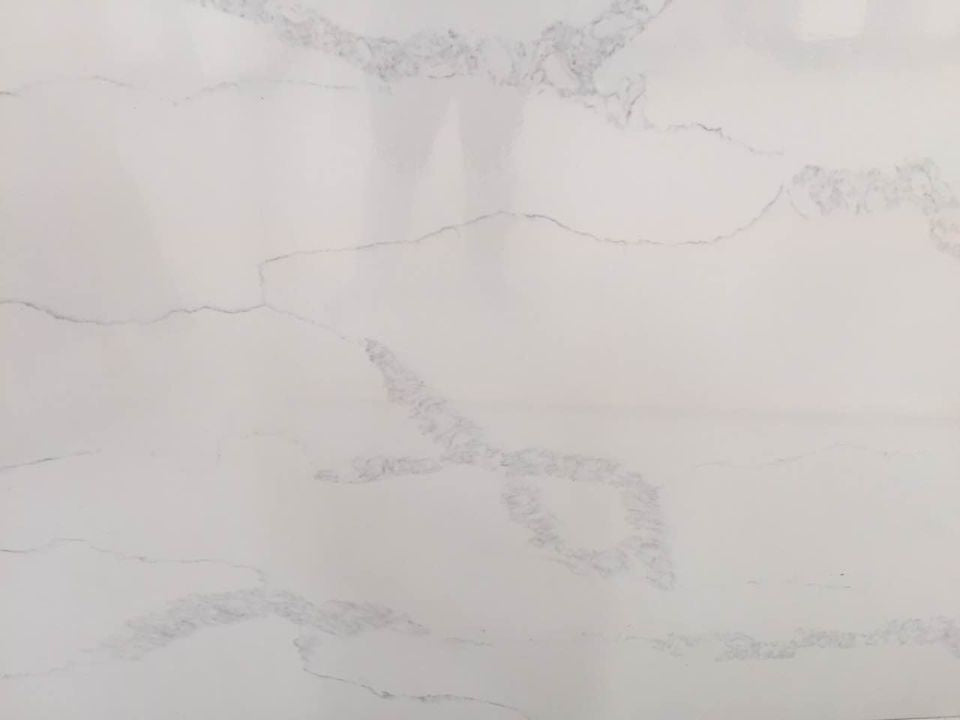

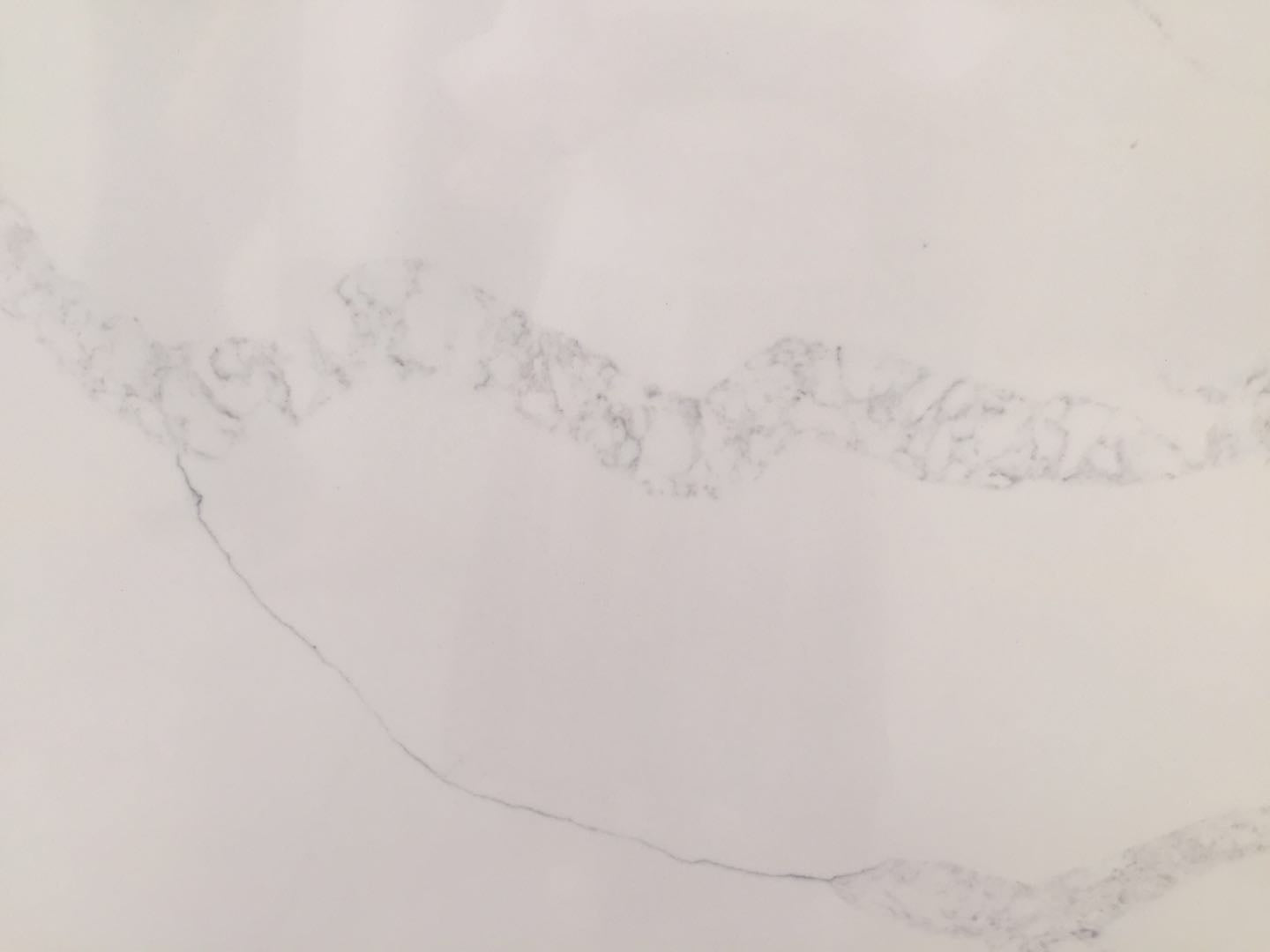

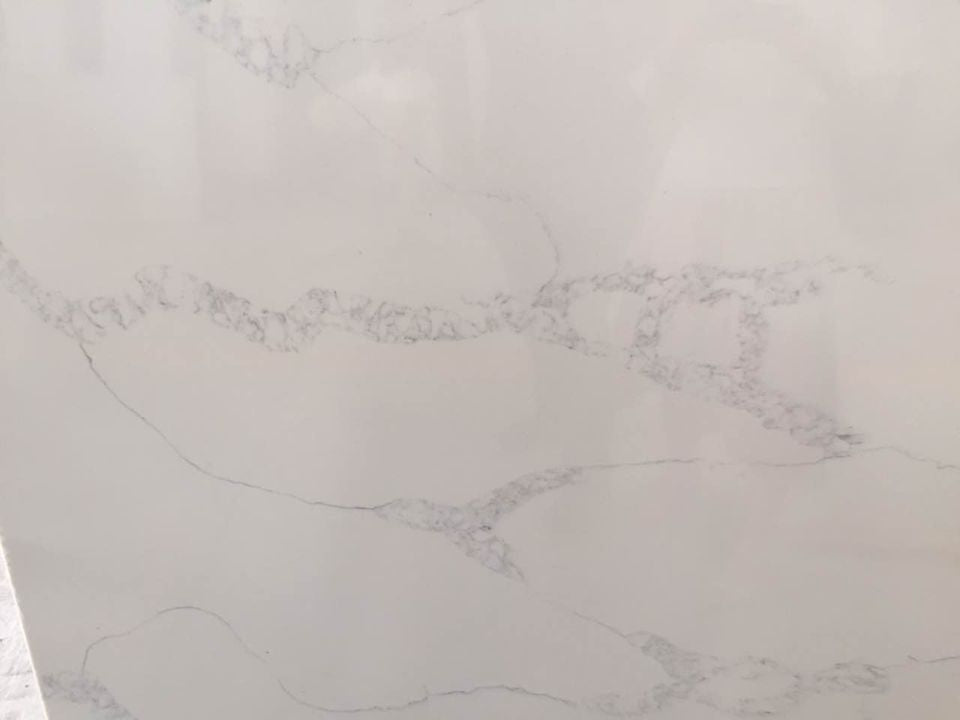

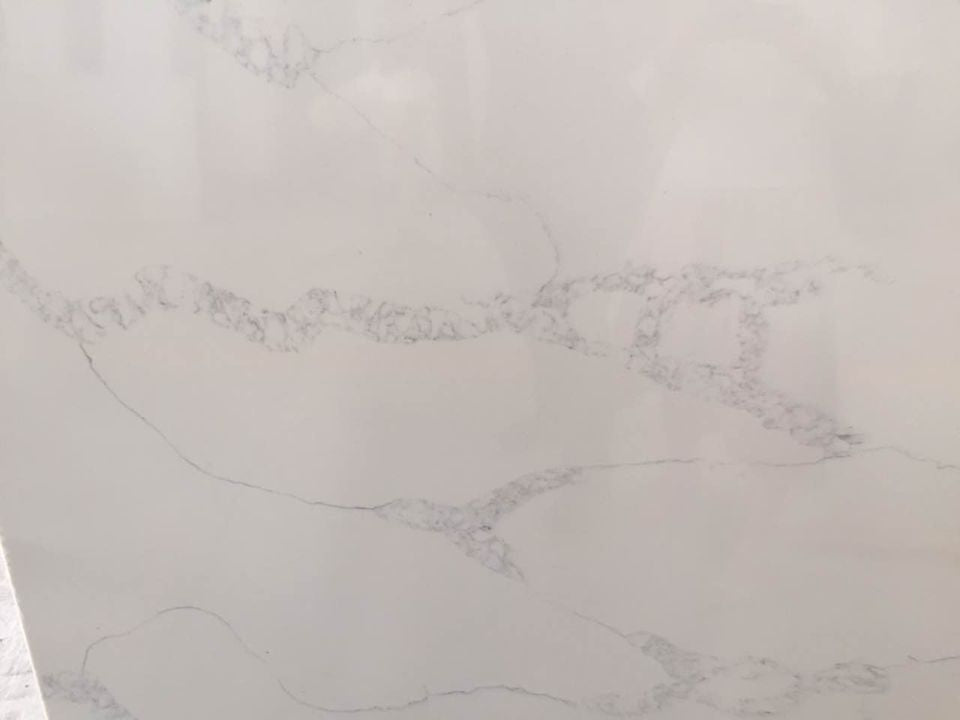

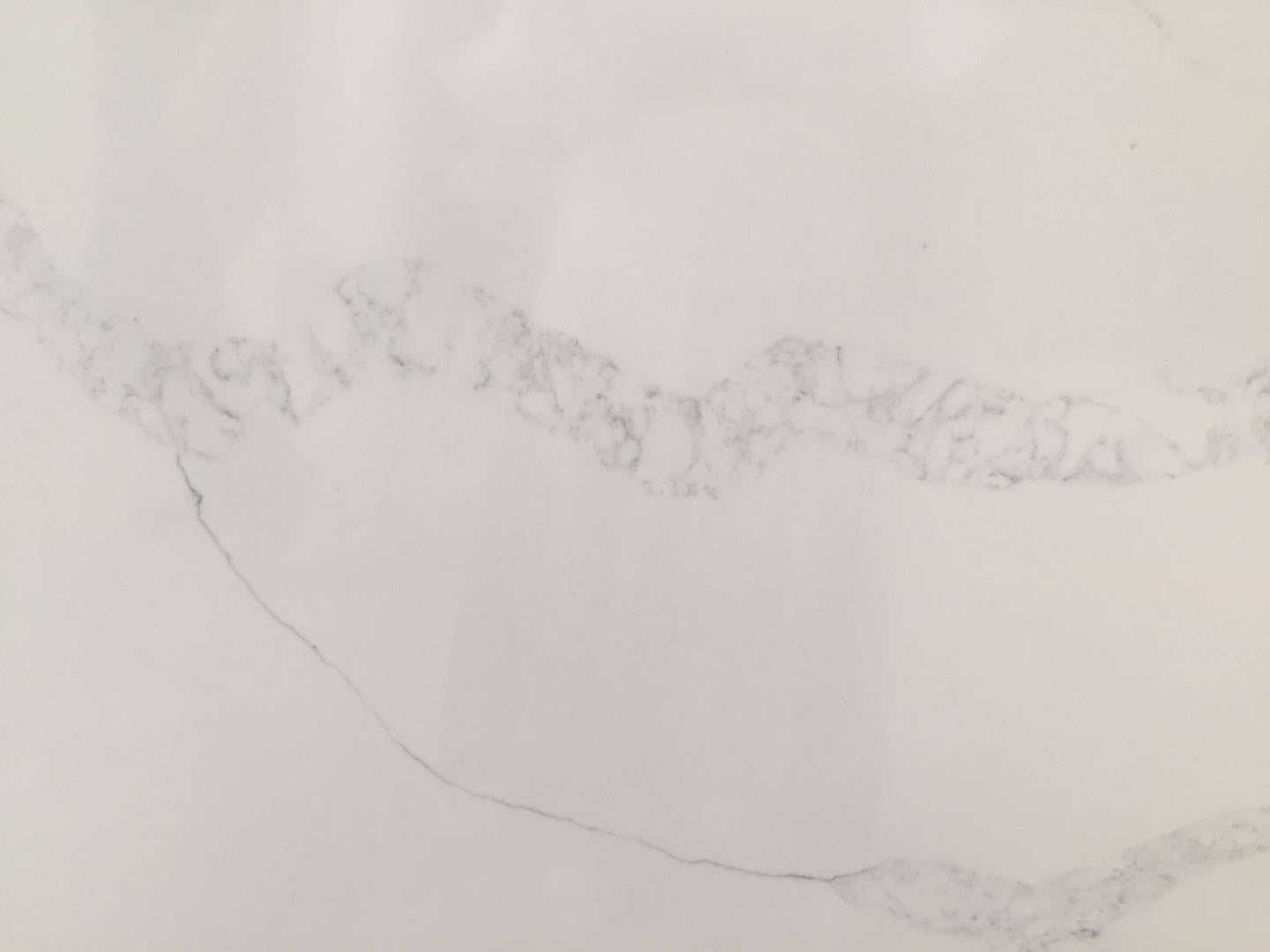

Calacatta Engineered Stone – Elegant Design Meets Lasting Performance

Expertly engineered, Calacatta Engineered Stone is a durable and elegant surface option. With its stunning Calacatta marble appearance, this stone provides a sleek and luxurious touch to any space. Made with high-quality materials, it offers long-lasting beauty and practicality, making it the perfect choice for any project.

| Feature | Details |

|---|---|

| Material | 93% Nature Quartz |

| Calacatta quartz engineered stone kitchen countertop Size | 96"x26", 108''x26''; |

| Island size |

|

| Vanity top Size: |

|

| Big Slab Size |

|

| Slab Size | 1400*3000 1600*3200 1800*3200 or cut to size |

| Thickness | 12mm, 15mm, 20mm,30mm |

| Surface | 100% full polished |

| Color range | Calacatta, marble looks, Carrara, basic colors, mixed colors |

| Slabs packing |

105 slabs 2cm per 20ft container and 70 slabs 3cm per 20ft container |

| Applications |

Kitchen countertop, bathroom vanity tops, benchtops, kitchen island, bar countertops,residential and commercial projects. |

| Delivery time | Around 20 days after getting the deposit |

In the world of interior design, Calacatta engineered stone has become a go-to material for modern homes. Known for its luxurious appearance, durable composition, and versatile application, it’s the ideal choice for countertops, feature walls, bathroom vanities, and bay window surfaces.

Whether you’re upgrading a kitchen or renovating an entire space, this sophisticated stone offers the perfect balance of beauty and practicality.

🛠 Proper Installation for a Seamless Finish

To ensure the longevity and aesthetic appeal of Calacatta engineered stone, proper installation is key. Here’s how to do it right:

- Pour the prepared glue evenly over the splicing interface. Ensure that the glue fills more than 1/2 of the reserved gap.

- Immediately fasten the spliced board surface using F clips or A clips, then carefully inspect the flatness.

- Use a rubber hammer to lightly tap and align the board if needed until the surface is perfectly flat.

⚠️ Important: During the glue curing period, avoid loosening the fixtures or placing heavy objects on the surface. Do not stand on the countertop as this could damage the integrity of the joint.

- Once the glue has fully cured, use a gong machine or angle grinder to remove excess glue and then smooth the surface with a grinder.

🚫 Never use a chisel, as this can damage the stone.

🌧 Mold Prevention in Humid Environments

Calacatta engineered stone is highly durable, but like all natural-based materials, it can develop mold if not properly cared for—especially in humid conditions like kitchens and bathrooms.

Why Mold Happens:

- Organic residue on the surface can promote mold growth.

- Humidity allows mold spores to settle in the stone’s porous capillaries, leading to black, brown, or green spots that are difficult to remove.

✅ Tips to Prevent Mold on Calacatta Engineered Stone:

- 💨 Ventilation is Key – Ensure proper airflow in high-moisture areas

- 💧 Wipe Surfaces Dry – Always dry the surface after cleaning or usage

- ❄️ Use Dehumidifiers or Air Conditioners – Maintain low humidity indoors

- 🧽 Regular Cleaning – Clean with non-acidic, pH-neutral stone-safe products

- ⏱ Prompt Spill Removal – Avoid letting liquids sit on the surface

Following these tips helps preserve the beauty of your Calacatta engineered stone and protects your investment for the long run.

✨ Where Can You Use Calacatta Engineered Stone?

This luxurious engineered surface is perfect for a wide range of home and commercial applications, including:

- 🏠 Kitchen countertops & islands

- 🛁 Bathroom vanities

- 🪟 Bay window countertops

- 🧱 Feature walls & backsplashes

- 🍽 Dining tables & custom furniture

💎 Why Choose Calacatta Engineered Stone?

- 🪨 Natural Marble Look – Beautiful veining with high-end finish

- 🔥 Heat & Scratch Resistant – Stands up to everyday kitchen use

- 💧 Non-Porous & Hygienic – Easier to clean, resists bacteria

- 🧱 High Strength & Durability – Engineered for long-term performance

- 🧼 Low Maintenance – Easy upkeep with stunning results

Choose Calacatta engineered stone for timeless style and unmatched durability—perfect for elevating any room in your home.

Share