Brushed Sandstone Floor Tiles

Brushed Sandstone Floor Tiles

Brushed Sandstone Floor Tiles – A Natural Choice for Elegant Paving

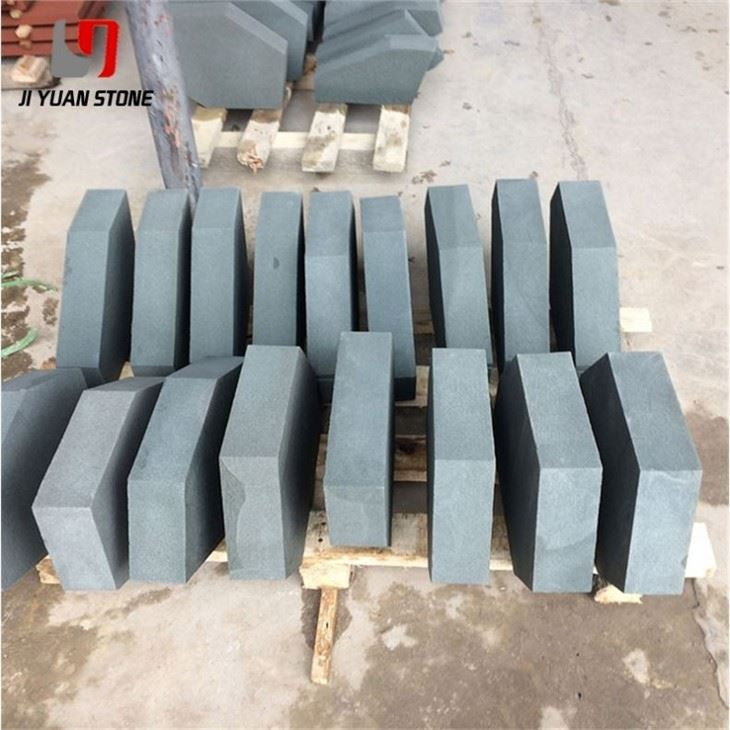

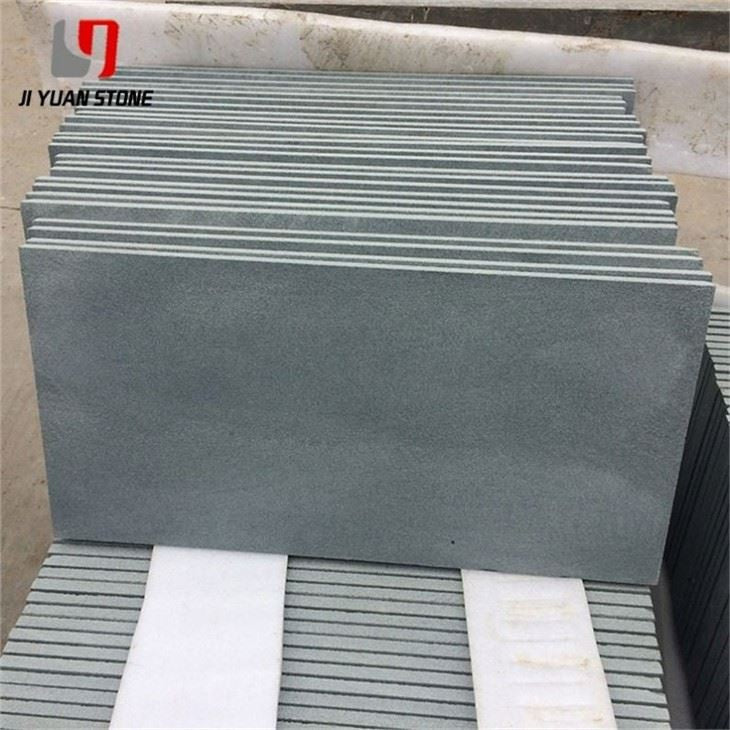

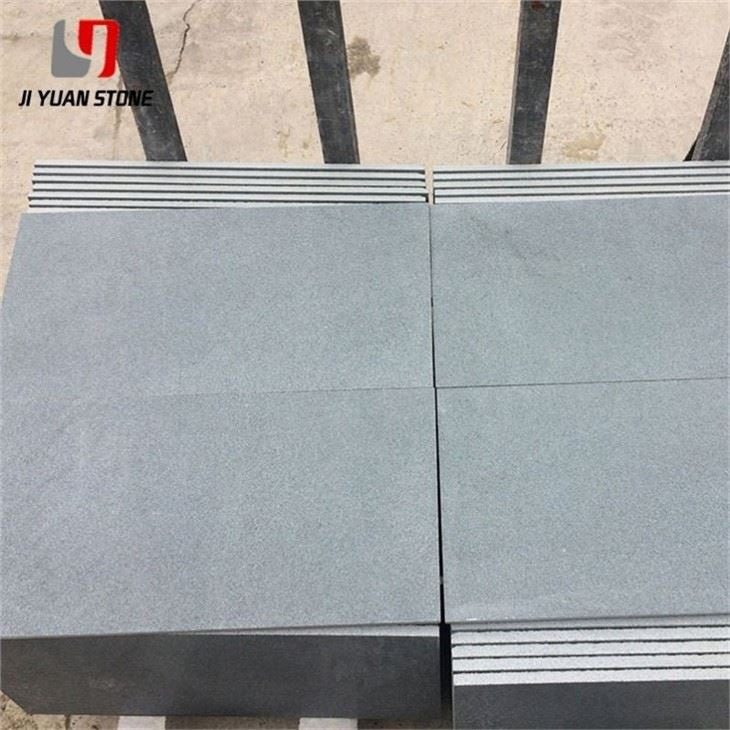

Enhance the look of your space with Brushed Sandstone Floor Tiles. These tiles offer a distinct texture that adds depth and character to any room. Made from high-quality sandstone, they are durable and easy to maintain. Upgrade your floors with these elegant and versatile tiles.

| Feature | Details |

|---|---|

| Material | Natural Sandstone |

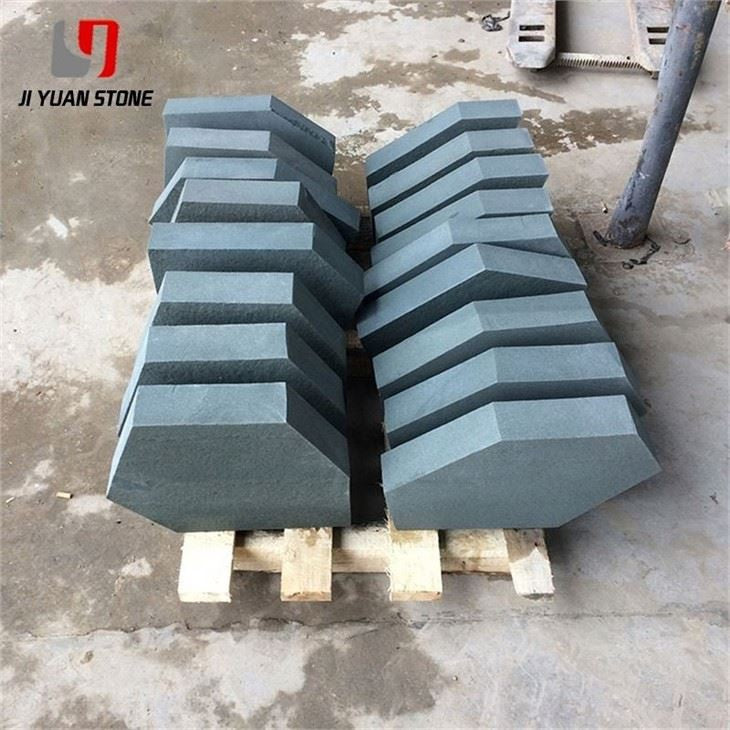

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Finished | Honed, Split, Sandblasted, Sawn, Antiqued, Pineapple, etc. |

| Dimension |

|

| Usage | Interior & Exterior Decoration |

| Quality Control |

Thickness Tolerance:+/-0.5mm,+/-1mm; All Products Checked by Experienced QC |

| MOQ | Welcome Small Trail Orders |

| Size | Customized Pls contact us for the newest catalog of sandstone,marble,granite,quartz,mosaic,limestone,travertine etc |

| Sample | Contact Us For Free Samples |

| Package | Standard Exporting Seaworthy Package ( Inner: Plastic Film and Foam; Outer: strong seaworthy wood Crates or Pallets.)Payment |

| Payment | T/T, L/C, Escrow, Western Union |

| Delivery | Within 2 Weeks After Deposit |

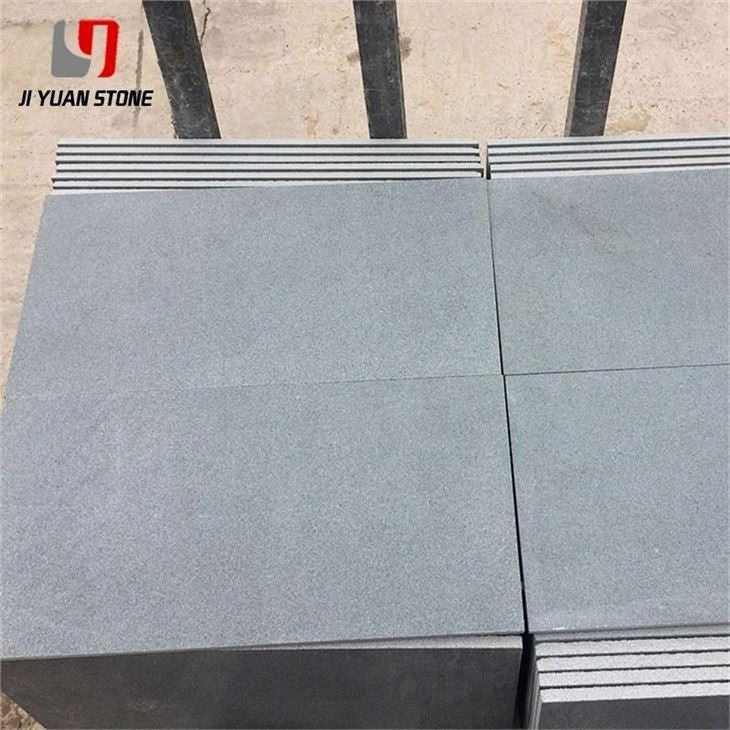

Brushed sandstone floor tiles are a timeless flooring solution known for their subtle textures, natural patterns, and versatility. Whether used indoors or in exterior landscaping, they offer both beauty and durability—making them a preferred choice for modern homes, luxury patios, and commercial environments alike.

These tiles are not only aesthetically appealing but also practical, with anti-slip properties and resistance to weathering. Their brushed finish adds a soft, refined texture, offering a more organic look compared to polished stones.

🏗️ Key Guidelines for Paving Sandstone Floor Tiles

Proper installation plays a vital role in maximizing the performance and visual appeal of sandstone floor tiles. Below are critical paving techniques and quality control measures to follow:

1. Dry Mortar Ratio & Paving Bonding Layer

- The cement-to-sand ratio should be 1:3 for optimal strength and workability.

- A quick test: Pick up the mixed mortar—if it holds shape when pressed but breaks apart when dropped, the consistency is ideal.

2. Layout Planning for Important Nodes

- Accurate stakeout is essential. Use both map staking and ground staking to ensure precision in layout.

- In areas where full modularity isn’t feasible, consider 45° splicing or using variable-sized plates in concealed zones like corners.

- For large surface areas, use tiles with uniform specifications to streamline construction and visual harmony.

3. Paving Gap & Seam Control

Sealed Paving:

- Gaps should not exceed 2mm.

- Use tools like iron wires or metal sheets for precise control.

Seam Paving:

- Follow design-specified seam widths.

- Tools like hanging lines or cross spacers help maintain consistency.

- The maximum foot difference between adjacent tiles should not exceed 1mm.

Jointing & Finishing:

- Use designated spacers or layout tools to achieve even, clean seams.

- Fine tools such as cross positioners or bamboo chips aid in maintaining uniform seam widths.

4. Large-Area Paving Guidelines

- For expansive floor areas, establish a cross control line system.

- The gap between control lines should not exceed 5 meters to prevent misalignment and drift over large spaces.

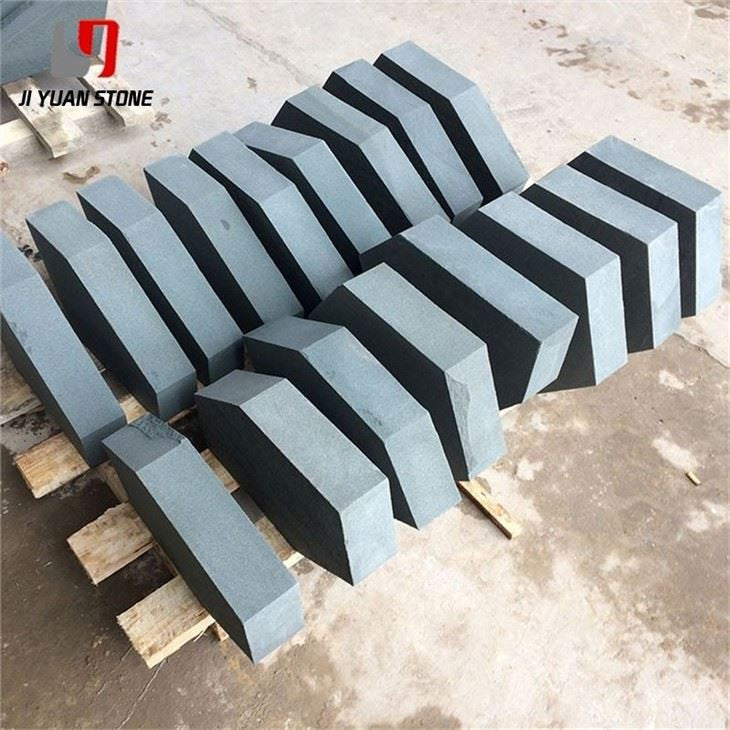

🧱 Why Choose Brushed Sandstone Floor Tiles?

- Natural Texture & Finish: The brushed surface showcases soft, tactile aesthetics with natural veining.

- Non-Slip Safety: Ideal for wet or high-traffic areas due to its slip-resistant properties.

- Weather Resistant: Suitable for indoor living rooms or outdoor walkways and patios.

- Timeless Look: Complements both contemporary and rustic design themes.

🏡 Applications

- Interior flooring (living rooms, hallways, entryways)

- Outdoor patios, garden paths, balconies

- Commercial lobbies or high-end retail spaces

- Pool decks and spa areas

Brushed sandstone floor tiles offer a harmonious blend of organic beauty, long-term durability, and easy maintenance. When installed with attention to detail and adherence to professional paving guidelines, they become a lasting asset to any space.

Elevate your flooring project today with the natural elegance of sandstone.

Share