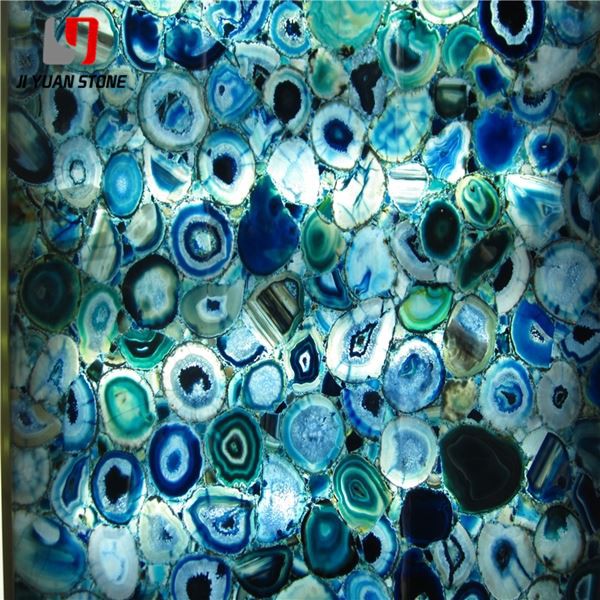

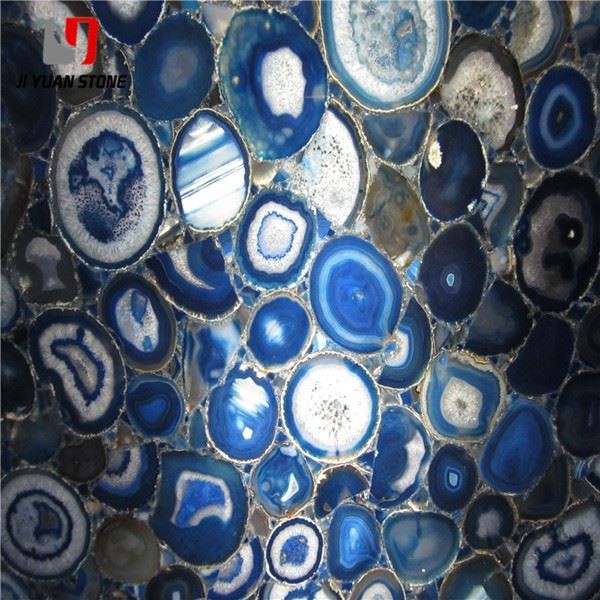

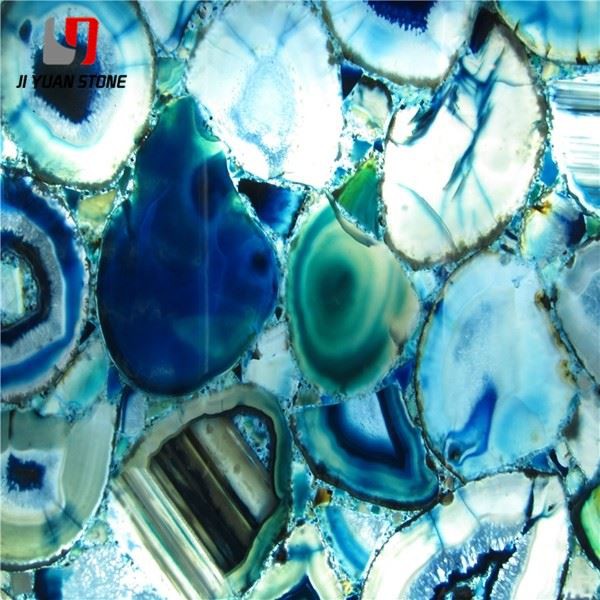

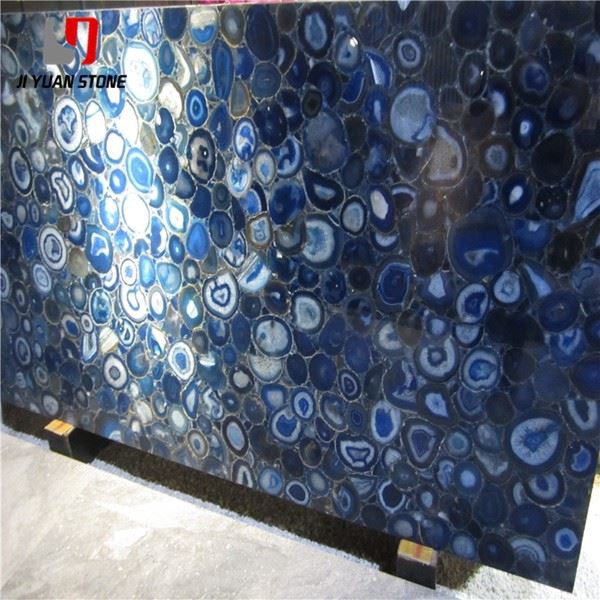

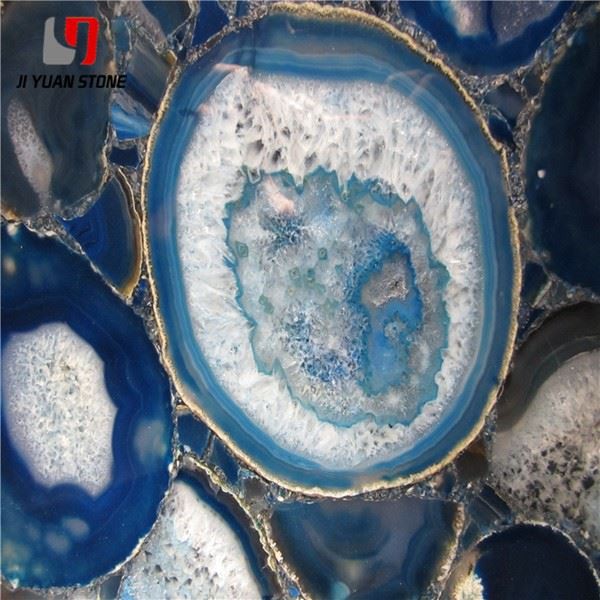

Blue Semi Precious Stone Tiles

Blue Semi Precious Stone Tiles

Introduce a touch of luxury to your space with our Blue Semi Precious Stone Tiles. Made from natural, high quality materials, these tiles add a unique and elegant touch to any room. With their beautiful blue hues and semi precious stone composition, they are sure to elevate the look and feel of your space.

| Feature | Details |

|---|---|

| Material | Blue Semi Precious Stone Tiles |

| Product Name | Agate Stone |

| Surface Finished | Honed,Polished |

| Finished Products | Floor Tiles, Wall Cladding, Countertops, Windowsills, Special-Shaped Tiles, Small Slabs, Swimming Pool, Steps, Wall Panel, Flooring, Veneers, Slabs, Coping Tiles etc |

| Colour | Yellow, Black, White, Red, Purple Wood, Green, Grey, Rainbow, Pink, Tiger Eye etc |

| Products | Slabs, Tiles, Skirtings, Window sills, Steps & Riser stairs, Kitchen countertop, Vanity tops, Worktops, columns, Paving stone, Mosaic & Borders, Sculptures, Tombstones |

| Tiles Size available |

|

Choosing the Right Installation Method for Blue Semi-Precious Stone Tiles

Many engineers have encountered this situation:

A dry-hanging installation was specified in the drawings but was executed as a wet sticker on-site—or vice versa. To avoid such discrepancies, it's essential to understand the different installation methods and their applications.

There are four primary installation methods for stone tiles:

- Dry Hang

- Wet Paste

- Wet Hang

- Dry Paste

Each method is suitable for different conditions. So, which one should you choose?

Today, we’ll analyze the process, cost control, and execution to determine the best approach for stone tile installation.

Understanding the Dry Hanging Process for Blue Semi-Precious Stone Tiles

Among all installation methods, dry hanging is the most widely used technique in the industry. Let's break it down into process, advantages & disadvantages, and specifications.

1. What is the Dry Hanging Process?

The dry hanging method involves fixing a base frame to the wall and then securing the slotted stone tiles onto the frame using dry hanging pieces.

Basic Installation Steps:

1. Fixing the Vertical Channel Steel

- Use galvanized steel sheets and expansion bolts to secure the vertical channel steel to the wall.

2. Welding the Horizontal Angle Steel

- The horizontal angle steel is welded and fixed onto the vertical channel steel.

3. Attaching the Dry Pendant

- The dry pendant is fixed onto the horizontal angle steel.

4. Securing the Stone Tiles

- The grooved stone tiles are finally placed onto the dry pendant.

2. Advantages & Disadvantages of Dry Hanging

✅ Advantages:

- High Security: Uses physical fixation (steel frame) rather than chemical bonding, ensuring better durability.

- No Efflorescence (No Return to Alkali): Since the stone is fixed with a steel frame, there's no risk of moisture damage.

- Excellent Seismic Resistance: The structure distributes stress evenly through the steel frame, making it highly resistant to earthquakes.

❌ Disadvantages:

- High Cost: Steel framing and labor costs are significantly higher than other methods.

- Slow Construction: The complexity of installation results in a longer construction time.

- Space Requirements: A minimum of 80mm of space is required for dry hanging. If the design allows for only 5cm of depth, this method cannot be used.

Making the Right Choice

Each installation method has its own strengths and limitations. By evaluating process efficiency, cost, and project conditions, you can determine the most suitable approach for installing blue semi-precious stone tiles.

Share