Black Travertine Marble

Black Travertine Marble

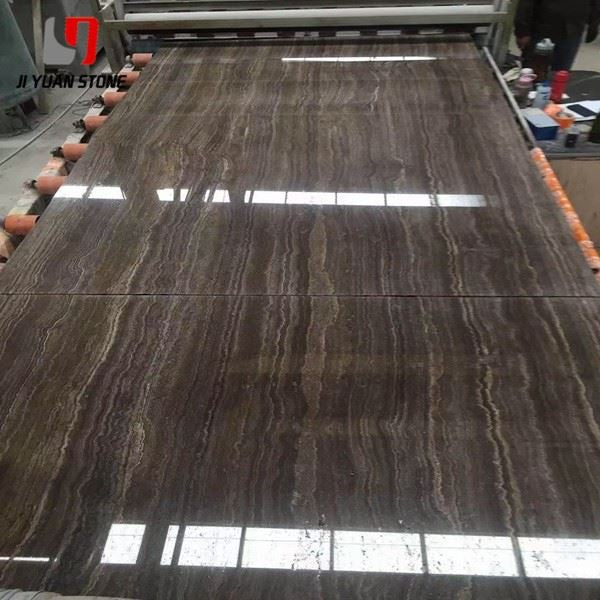

Black Travertine Marble – Premium Architectural Stone with Secure Dry Hanging System

Discover the elegance of Black Travertine Marble. This natural stone boasts a rich, dark hue perfect for adding a touch of sophistication to any space. Its durable composition and unique patterns make it a stunning choice for countertops, flooring, and more. Elevate your design with Black Travertine Marble.

| Feature | Details |

|---|---|

| Product Name | Black Travertine Marble |

| Material | Natural Travertine Marble Stone |

| Colour | Black, White,Grey, Silver,Red, Yellow,Ivory White, Beige etc |

| Thickness | 1mm,8mm,10mm,15mm,18mm,20mm etc |

| Usage | Pool coping,pavers,floor tile,wall panel,countertop,table etc |

Black Travertine Marble is a luxurious and durable stone that adds striking elegance to any architectural project. Its deep black tones and subtle natural veining make it a top-tier choice for building facades, commercial cladding, and interior accent walls. Designed for modern structural integration, this marble is ideal for dry hanging applications, particularly using the back-bolt anchoring method for maximum safety and aesthetic alignment.

🏗️ Hidden Structural Review Drawing for Dry Hanging Systems

A hidden structural review drawing is a vital component of every Black Travertine Marble installation where dry-hanging methods are used. It aligns directly with the stone layout drawing and includes:

- Layout of channel steel and angle iron

- Placement of embedded steel-reinforced plates

- Design guidance for future maintenance and repairs

- Complete drawings of embedded components and structural anchors

- Anti-rust treatment specifications for all auxiliary metal elements (especially at solder joints)

This documentation ensures safety, consistency, and long-term durability for dry-hanging installations.

🔩 Back-Bolt Method for Dry Hanging Black Travertine Marble

The back-bolt system is a high-performance method for installing marble cladding panels. It allows each slab of black travertine marble to be fixed independently to the substructure, ensuring structural integrity and a clean visual finish.

✅ Advantages of the Back-Bolt Method:

- Independent Load Bearing – Panels can be installed or replaced individually without disturbing others

- Enhanced Seismic Resistance – Reduces structural stress and enhances overall safety

- Smooth Surface Finish – Guarantees evenness across the entire marble wall

⚠️ Considerations and Limitations:

- Stone Thickness Requirement – A minimum of 25mm is needed (30mm recommended)

- Space Requirement – Requires 250–300mm between the marble surface and wall base

- Specialized Processing – Each panel must be factory-drilled with four precise back bolt holes

- Panel Size Limits – Panels should not exceed 1.5 square meters; pendants typically made from stainless steel

🔧 Back-Bolt Installation Process for Black Travertine Marble:

1. Drilling – Using precision tools, conical holes ("large inside, small outside") are made at the back of each slab

2. Anchor Bolt Insertion – Anchor bolts are inserted into the prepared holes

3. Tightening – Bolts expand within the hole to form a tight grip

4. Convex Joint Formation – The fit is seamless and stress-free, ensuring long-term structural integrity

5. Final Fixing – The stone is securely mounted to the metal framework with professional-grade fasteners

✨ Why Choose Black Travertine Marble?

- Deep black tone with refined natural veining

- Suitable for both interior and exterior architectural elements

- Compatible with dry hanging systems, especially for high-rise facades

- Resistant to weathering and structural distortion

- Adds luxury appeal to modern and classic designs

🏢 Perfect For:

- High-rise Building Cladding

- Lobby and Feature Walls

- Hotel & Commercial Interiors

- Modern Villas & Estates

- Façade Panels with Back-Bolt Fixing Systems

🛒 Elevate Your Architecture

Black Travertine Marble is more than a stone – it’s a statement of durability, engineering, and design. Perfect for projects where safety and beauty go hand in hand, this marble paired with the back-bolt dry hanging system ensures your architectural masterpiece stands strong and stunning for decades.

Share