Black Terrazzo Tile

Black Terrazzo Tile

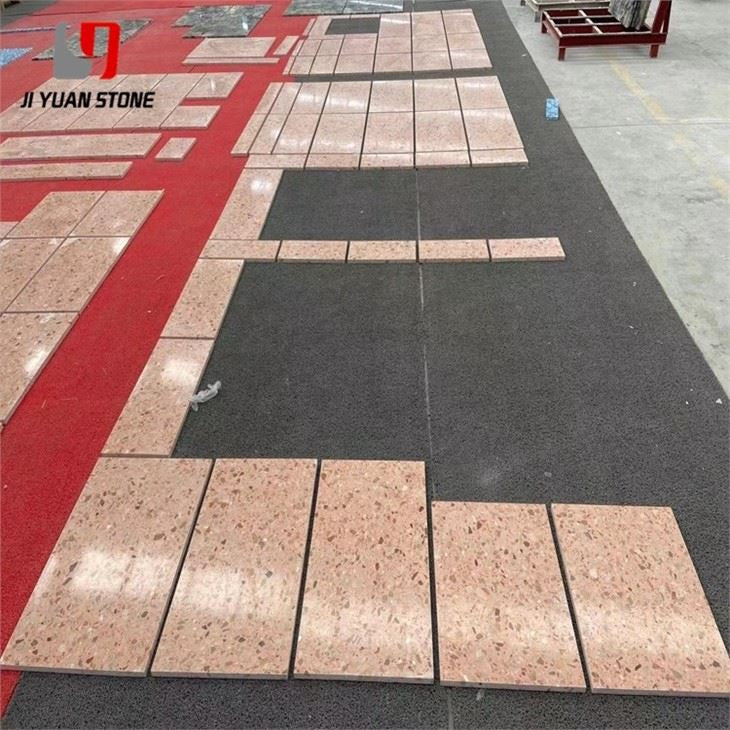

Black Terrazzo Tile – Bold Aesthetics with Precision Installation

The Black Terrazzo Tile is a sleek and sophisticated flooring option for any space. Made from high-quality materials, this tile offers durability and ease of maintenance. Its striking black color adds a touch of elegance to any room. Upgrade your floors with the Black Terrazzo Tile today.

| Feature | Details |

|---|---|

| Material | Terrazzo |

| Surface Finish | Polished,Honed |

| Common Slabs sizes |

|

| Common Tile sizes |

|

| Countertops Size |

|

| Vanity Tops Size |

|

| Edge Style | Bull nose, ogee, bevel, eased, polish, etc |

Elevate your interiors with the timeless beauty of black terrazzo tiles—an ideal choice for architects, designers, and homeowners seeking a contemporary, durable surface. Known for their bold visual impact and long-lasting performance, black terrazzo tiles are perfect for high-traffic commercial areas, modern homes, and artistic architectural projects.

🛠️ Process for Laying and Grinding Black Terrazzo Tile Surface

Proper installation is key to achieving the refined, high-performance look that terrazzo is known for. Below is a step-by-step breakdown of how black terrazzo tiles are laid and finished for maximum durability and aesthetic appeal:1. Surface Preparation and Protection

- Ensure grid inserts are securely stabilized.

- Begin by sprinkling water for curing over 3–4 days before laying the surface mixture.

- Protect grid inserts from bending or damage throughout the installation process.

2. Laying the Cement and Stone Mixture

Color Application Sequence:

- Start with darker colors first, followed by lighter shades.

- Apply terrazzo to larger areas before borders to maintain uniform color and texture.

- Allow the first layer to set completely before layering additional cement-stone mixtures.

- Avoid mixing multiple colors at once to prevent contamination.

Mixing Instructions:

- Accurately measure all materials.

- Dry mix cement and pigment, then add stone chips and mix evenly.

- Add water last for a consistent 60mm mix.

- When using mixed stone sizes or colors, pre-mix thoroughly.

Bonding Layer Application:

- Apply a cement slurry bonding layer (same color as surface) with a 0.4–0.5 water-cement ratio before laying the surface.

- Spread the mixture 1–2mm higher than grid inserts.

- Roll, compact, and smooth with a trowel.

- If stone exposure is insufficient, manually embed more stone chips.

Alternative Method – Dry Stone Sprinkling:

- After leveling, sprinkle washed dry stones over 1/3 to 1/4 of the surface.

- Pat dry stones into the slurry, compact with a roller, and finish with a smooth trowel.

- Ensures strong bonding and a visually rich terrazzo surface.

3. Curing and Grinding Process

Surface Curing:

- No foot traffic immediately after laying.

- Begin watering after 24 hours.

- Standard curing time: 5–7 days, extended to 10+ days in colder climates.

Trial Grinding:

- Conduct a trial grind to verify stone adhesion.

- Begin full grinding only after approval.

- For larger projects, wait at least 15 days before grinding begins.

4. Grinding Timeline Based on Temperature

| Avg Temp (℃) | Machine Grinding | Manual Grinding |

|---|---|---|

| 20 – 30 | 2 – 3 days | 1 – 2 days |

| 10 – 20 | 3 – 4 days | 1.5 – 2.5 days |

| 5 – 10 | 5 – 6 days | 2 – 3 days |

🧱 Why Choose Black Terrazzo Tiles?

- Striking appearance that enhances modern and minimalist designs

- Highly durable and suitable for commercial and residential flooring

- Customizable installation methods ensure optimal results

- Resistant to wear, impact, and daily usage

- Eco-friendly, made using recycled stone and cement

Share