Black Terrazzo

Black Terrazzo

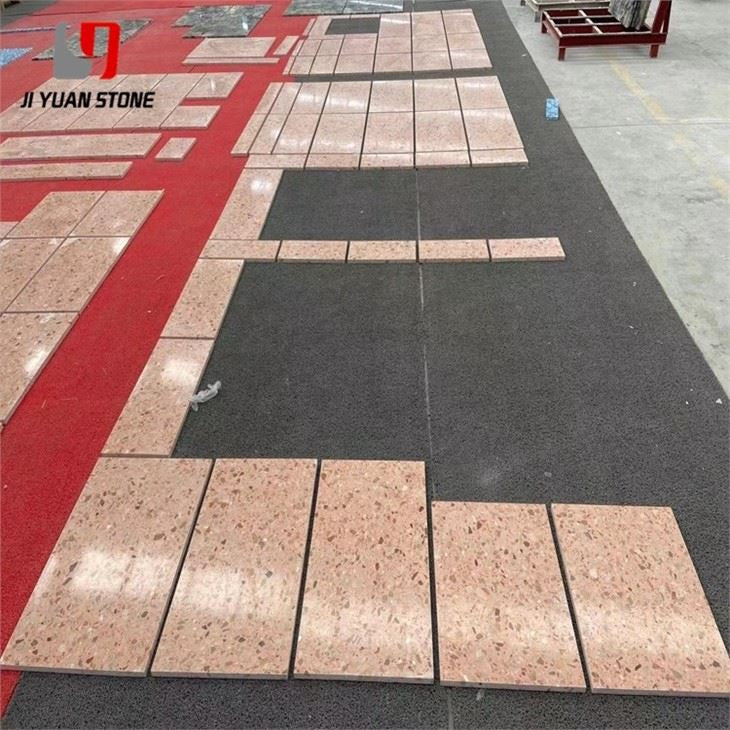

Black Terrazzo Tiles – Durable Elegance with High Compressive Strength

Enhance any space with our high-quality Black Terrazzo. Crafted from natural materials, this versatile product adds a touch of elegance and durability to any surface. Its sleek black finish complements any design and is perfect for both residential and commercial use.

| Feature | Details |

|---|---|

| Material | Terrazzo |

| Surface Finish | Polished,Honed |

| Common Slabs sizes |

|

| Common Tile sizes |

|

| Countertops Size |

|

| Vanity Tops Size |

|

| Edge Style | Bull nose, ogee, bevel, eased, polish, etc |

Create bold, modern, and durable spaces with our black terrazzo tiles, engineered for strength, longevity, and a striking visual appeal. With a compressive strength of 100–130 N/mm² using the soft grinding method, these tiles are ideal for both commercial and residential applications where performance and aesthetics are equally important.

Our black terrazzo tiles are meticulously ground and polished in multiple passes to ensure a dense, smooth surface that highlights the embedded stone particles with exceptional clarity and gloss.

🧱 Construction Features & Polishing Process

1 . Start Timing After Polishing

The curing days begin after the terrazzo surface is compacted and polished, ensuring structural integrity and consistent finish quality.

2 . Soft Grinding Method

When using the soft grinding method:

- The compressive strength of the surface reaches 100–130 N/mm²

- Grinding can begin once stone particles are stable and not loose

- This speeds up construction without compromising surface quality or grid strip adhesion

3 . Polishing Sequence

- Minimum three polishing passes for regular finishes

- High-grade terrazzo may require additional passes and finer stones

- First polishing pass uses No. 54, 60, and 70 oilstones

- Subsequent passes progress to No. 90–240 oilstones

- Each stage includes water spraying, slurry cleaning, and pore/dent filling

- Final surface should be smooth, even, and stone grains fully exposed

4 . Oxalic Acid Treatment

After polishing:

- Apply an oxalic acid solution (1:0.35 hot water to oxalic acid ratio)

- This enhances the natural shine and mirror-like finish

5 . Waxing Process

After all surface-affecting procedures are done:

- Prepare wax with 500g Sichuan wax + 2000g kerosene + 300g pine perfume + 50g fish oil

- Apply a thin layer wrapped in cloth

- Final buffing with canvas-mounted wood blocks or a waxer

- Cover with sawdust for curing to lock in the sheen

🛠️ Installation Safety & Protection

- Always protect the finished terrazzo layer from impact or collision during construction

- Ensure stone grinder safety: use proper insulation, secure rubber cables, and install leakage trip protection on switchboards

✅ Why Choose Our Black Terrazzo?

- Ultra-durable with compressive strength up to 130 N/mm²

- Multi-stage grinding ensures smooth, pore-free surfaces

- Deep black tone with polished aggregate for luxury aesthetics

- Suitable for hotels, galleries, modern offices, and upscale residential flooring

- Easy maintenance and long-lasting shine

🏆 Elegant Finish Meets Industrial-Grade Strength

Whether you’re outfitting a sleek interior lobby or a modern commercial space, black terrazzo tiles offer the ideal blend of high-end aesthetics and performance engineering. Polished, protected, and built to last—this flooring solution delivers on every level.

👉 Order today or connect with our experts for bulk orders, design guidance, and installation support.

Share