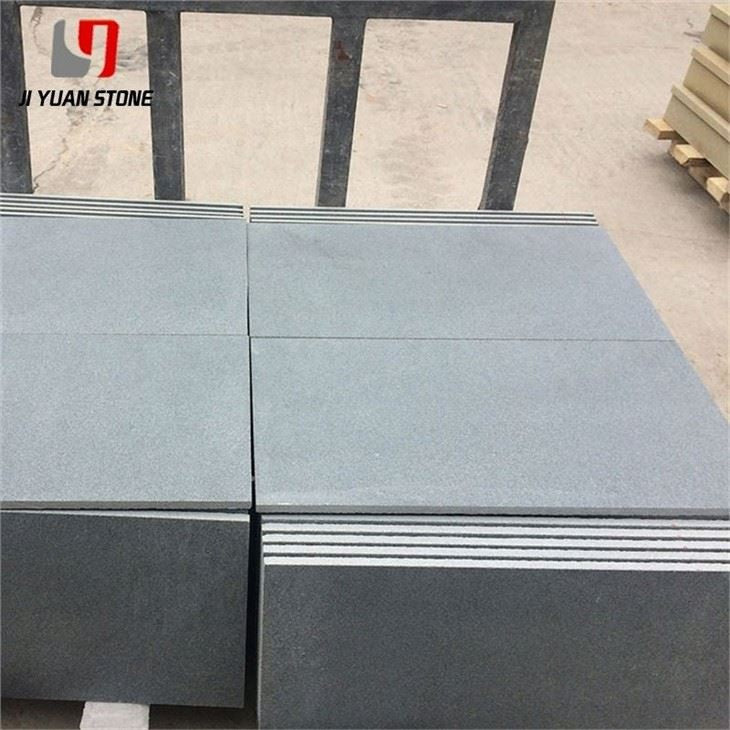

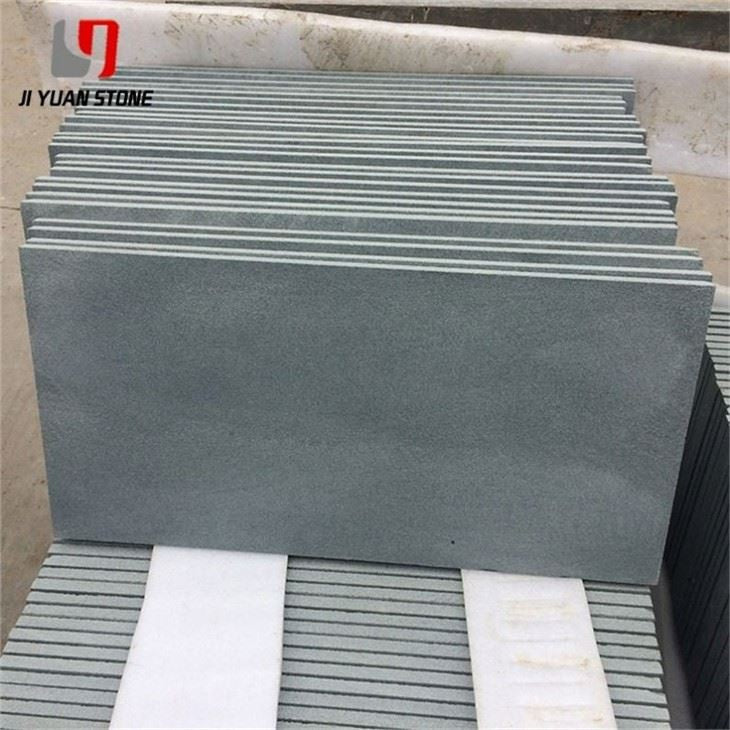

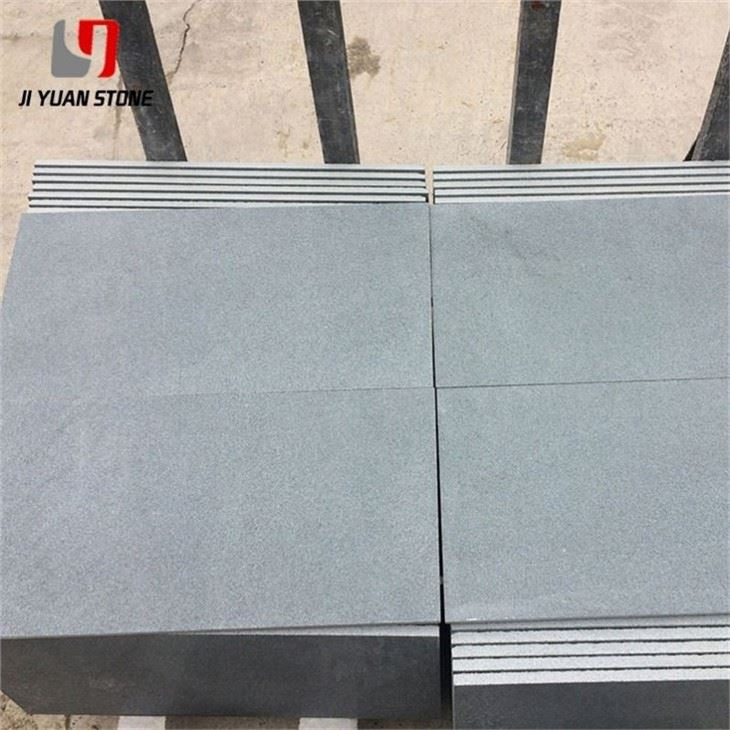

Black Sandstone Edging

Black Sandstone Edging

Elevate your landscaping with our Black Sandstone Edging. Made from durable sandstone, this edging provides a sleek and modern look to any outdoor space. Perfect for defining borders and creating a clean and polished aesthetic. Upgrade your garden with ease and style.

| Feature | Details |

|---|---|

| Materia | Natural Sandstone |

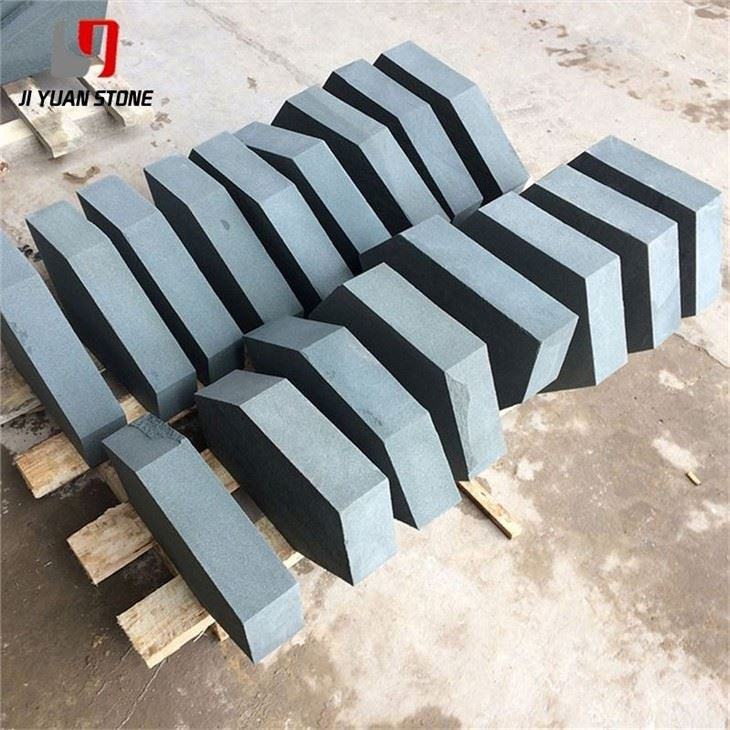

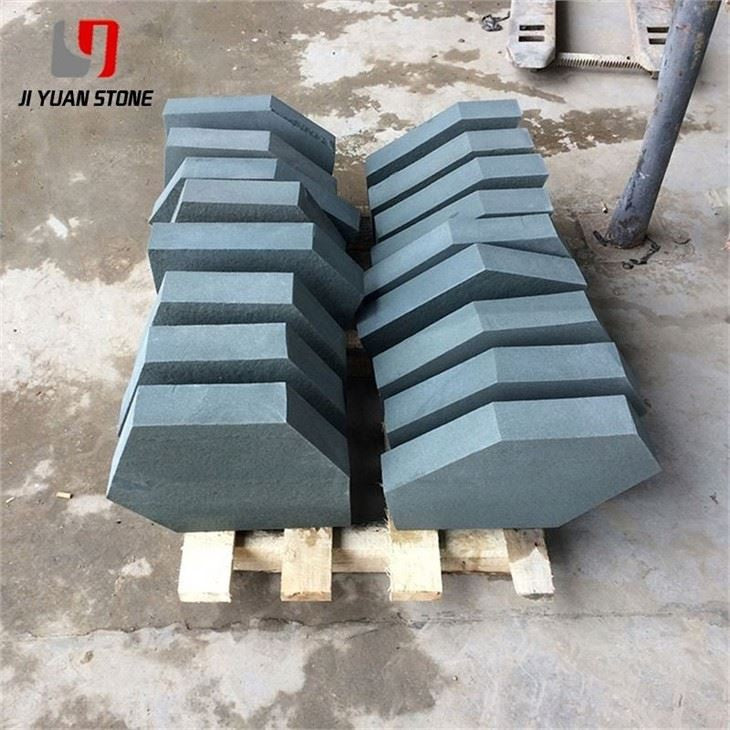

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

Xiamen Ji Yuan Stone Co.,Ltd. is a leading manufacturer and exporter of all kinds of natural stone products in China. We have our own 3 quarries and 5 production bases in the major stone areas in China. We are equipped with the most advanced machines, skillful workers. responsible Quality Inspectors and also another very professional managing team. As a professional world-class natural stone supplier. we promise our valuable customers: * All inquiries/questions to be replied to within 24 hours * Price is the most competitive * To provide 100% on-time delivery for products and documents delivery. * To have strict quality control policies and strict execution to deliver products with no defects in quality and strong seaworthy packing. * To keep very good communication with customers if any questions during production. * All claims to be settled within 24 hours * To keep continuous improvement on management. Our slogan---We try to do things to our customers' most satisfaction

Stone Mining and Processing Process

1. Block Mining Process:

- Caprock stripping

- Separation

- Top turning

- Disintegration and division

- Shaping

- Lifting and loading

- Removal

2. Stone Processing:

- Sawing Processing: Uses a stone sawing machine to cut granite blocks into rough boards, strips, blocks, and other shapes.

- Grinding and Polishing: Starts with rough grinding and leveling, followed by semi-fine grinding, fine grinding, and polishing.

- Cutting Process: Cuts rough or polished slabs to required specifications using a cutting machine.

-

Chiseling Processing: Shapes raw stone into required products through wedging, chiseling, chopping, trimming, and polishing. The surface can have various finishes, including:

- Pineapple surface

- Longan surface

- Lychee surface

- Natural surface

- Mushroom surface

- Brushed surface

- Singeing Processing: Uses flames to burn the surface, creating a rough, undulating texture (burning surface).

- Auxiliary Processing: Includes edge work, chamfering, hole drilling, groove milling, and other finishing touches as required.

- Inspection and Repair: Involves cleaning, blow-drying for inspection, and packaging of qualified products for storage.

3. Rough Board Specifications:

- 60 Heads: Refers to a width of 60 cm, with varying lengths (usually around 2 meters). Common sizes also include 70 heads, 80 heads, 90 heads, and 1-meter heads.

- In garden landscaping, 60 heads are commonly used.

- The larger the block size, the higher the unit price.

- In garden landscape design, material specifications should be carefully considered to minimize waste—especially for topping materials and arc-cutting materials.

Share