Black Quartz Vanity Top

Black Quartz Vanity Top

Black Quartz Vanity Top – Durable, Stylish & Long-Lasting Countertops

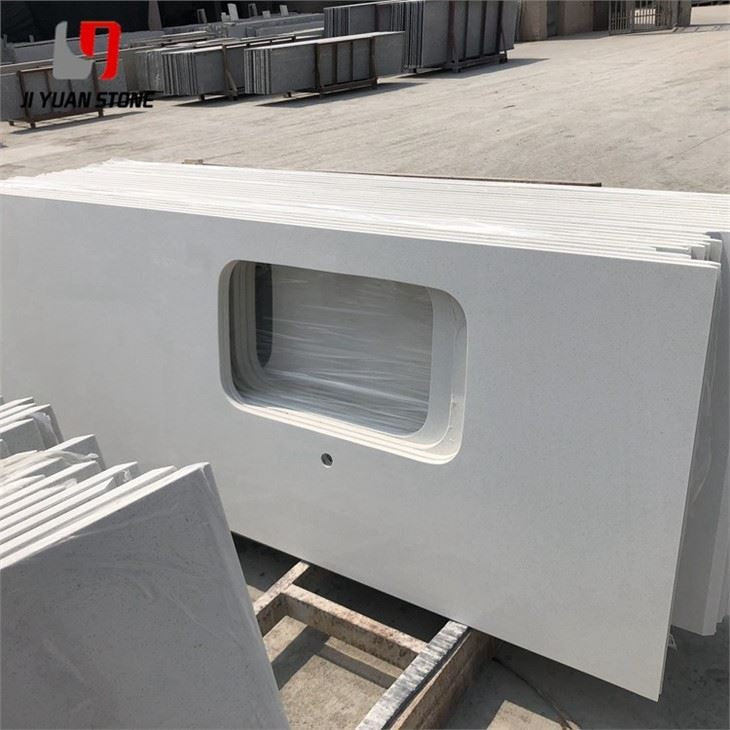

Expertly crafted with a sleek, modern design, our Black Quartz Vanity Top adds a touch of sophistication to any bathroom. Made from durable black quartz, it is not only aesthetically pleasing but also highly resistant to scratches and stains. Upgrade your bathroom with this timeless piece.

| Feature | Details |

|---|---|

| Material | 93% quartz powder, 7% resin and pigment. |

| Standard Size |

|

| Thickness | 12mm; 15mm; 18mm; 20mm; 30mm |

| Color |

|

| Usage | Slab, Countertop, Kitchen top, Vanity top, island top, Tabletop, Floor, Wall tile, Decorative Borders, threshold, windows sill, tub surround, shower tray and so one |

| Product feature |

1)The product is very hygienic 2)Resistant to scratch,wear,shock. 3)Excellent heat resistance,corrosion resistance. 4)Easy to clean and maintain 5)Anti-Depigment,Anti-penetration,Anti-Porous 6)Environmental friendly building materials. |

| Dimensional Stability | A grade |

| Certificate |

1)The Biggest and leading Group in China. 2) Passed certification of CE and ISO9001:2000 |

| Package | Wooden bundles, wooden crates and wooden cases, plywood case |

| Delivery time | Within 10-15 days after received 30% deposite |

The Black Quartz Vanity Top is one of the most popular choices for modern bathrooms and kitchens. Known for its elegant appearance, durability, and resistance to wear, quartz stone has become an ideal vanity top material that enhances both functionality and design.

It is estimated that everyone is familiar with quartz stone, it is an ideal vanity top material. The processing and installation of black quartz vanity top is a technical activity. If the quartz stone is installed improperly, it will not only affect the appearance of the cabinet vanity tops, but also directly affect the overall quality and service life of the cabinet.

That’s why proper design, processing, and installation are key to ensuring your quartz vanity top remains beautiful and functional for years.

🔹 Why Choose a Black Quartz Vanity Top?

- Elegant Look – Sleek black finish complements both modern and classic interiors.

- Durability – Highly resistant to scratches, stains, and moisture.

- Low Maintenance – Easy to clean and resistant to daily wear.

- Versatile Use – Perfect for bathroom vanities, kitchen countertops, and custom designs.

🔹 Precautions for Processing & Installation

Quartz stone vanity top installation precautions – what should you know before installation?

To ensure the best results, the following points must be considered:

1 . Splicing Position – Quartz stone is usually installed by splicing. Avoid corners and furnace openings, as quartz expands and contracts with heat, which may cause cracking.

2 . Corner Design – Stress concentration at corners can cause cracks. Keep all corners at a radius of at least 2.5 cm during processing.

3 . Opening Position for Stoves – Ensure openings are ≥ 8 cm from the edge of the vanity top. Use a gong machine or hand grinder for smooth edges. Uneven or serrated edges may cause cracks at openings.

4 . Reinforcement & Heat Protection – The corners of openings should be rounded with a radius > 2.5 cm. Reinforce with homogeneous plates, leave a 0.4–0.6 cm gap between the stove and vanity top, and use heat insulation cloth and tin platinum paper for protection.

5 . Transport & On-Site Installation – Consider restrictions such as stairs, elevators, and doorways. On-site joints must follow the correct splicing requirements for safety and durability.

Quartz stone has become a commonly used material for vanity tops. In order to ensure the quality of vanity tops, everyone needs to process and design the quartz stone before installation.

🔹 Applications of Black Quartz Vanity Top

- Bathroom vanity tops

- Kitchen countertops

- Custom furniture tops

- Commercial interiors requiring durability & elegance

✅ Conclusion

The Black Quartz Vanity Top is not just stylish—it’s built for strength, longevity, and beauty. With the right processing and installation techniques, it can last for decades without losing its elegance.

Upgrade your home or project with a black quartz vanity top that combines modern luxury with unmatched performance.

Share