Black Quartz Slab

Black Quartz Slab

Black Quartz Slab – High-Quality, Durable & Engineered for Excellence

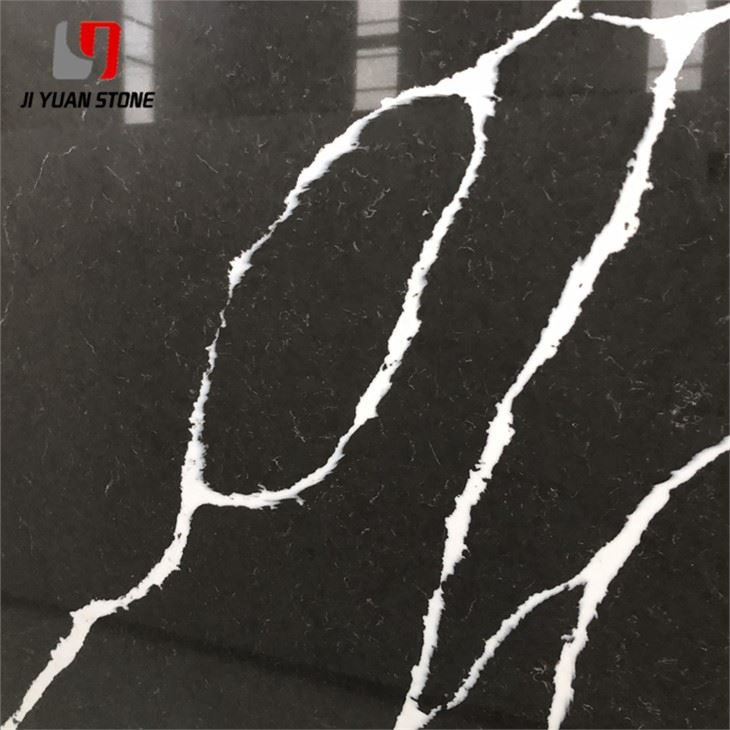

Upgrade your kitchen or bathroom with our elegant Black Quartz Slab. Made from high-quality materials, this durable slab adds a touch of sophistication to any space. Its sleek, modern design is perfect for those looking to elevate their interior design. Revamp your home with our Black Quartz Slab today.

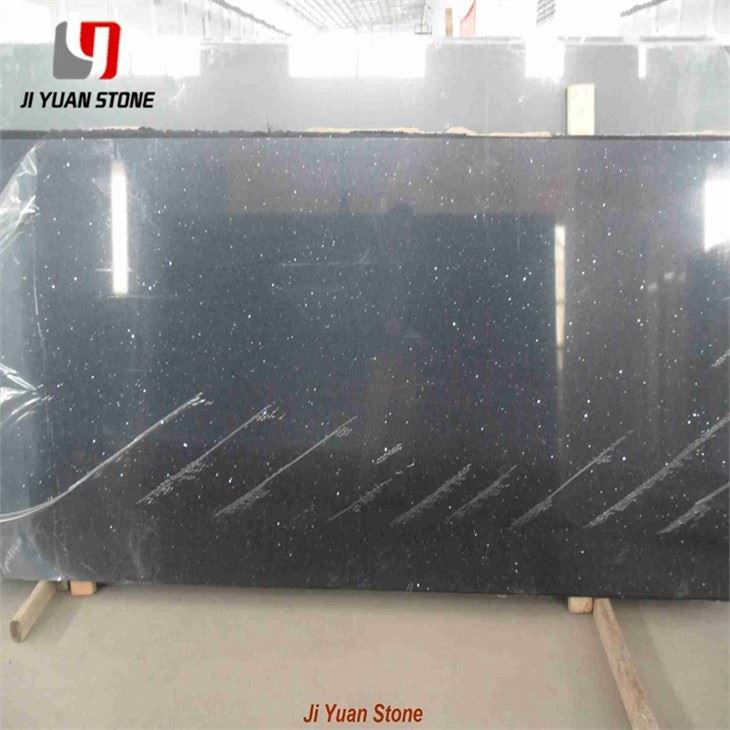

The Black Quartz Slab is a cutting-edge engineered surface created for those who demand both performance and beauty. Crafted with over 93% pure quartz and only 6–7% resin, this slab offers unparalleled strength, scratch resistance, and durability. Unlike lower-quality alternatives in the market, our slabs closely replicate the texture and resilience of natural stone, thanks to a lower resin ratio and superior quartz content.

Developed from industry innovation, Black Quartz Slab was originally invented by the renowned Italian company Bailitong, which revolutionized the quartz slab industry. While Bailitong continues to lead in automated production with 14 plants globally, China’s Bevron has risen to the challenge, investing heavily in R&D to master quartz slab production technology. The result? A world-class slab with performance that rivals global leaders.

🌟 Product Characters:

A. Scratch-Resistant

Resistant to knife scratches and daily wear—ideal for high-traffic areas like kitchen countertops.

B. Stain-Resistant

Easily repels stains from coffee, fruit juice, tea, oil, and more—perfect for kitchens and bathrooms.

C. Bacteria-Resistant

Safe for direct food preparation. A non-porous surface ensures hygiene and cleanliness.

D. Acid & Alkali Resistance

Withstands lemon juice, vinegar, and other acidic or alkaline substances without etching or dulling.

E. Maintenance-Free

Unlike granite, there’s no need to seal. Simple cleaning with soapy water keeps the surface spotless.

F. Extremely Durable

Engineered to last for decades with minimal signs of wear, retaining its original gloss and strength.

G. Rich in Pattern and Color

Available in an array of stylish hues including black, white, beige, red, and pink—perfect for every design aesthetic.

⚙️ Unmatched Manufacturing Standards:

Bevron’s black quartz slab production has closed the technology gap with industry leaders like Bailitong by achieving:

- Quartz content of 93–94% (far superior to many domestic brands)

- Resin content reduced to 6–7% (compared to 10%+ in low-quality slabs)

- Stable structure that minimizes deformation, discoloration, and brittleness over time

- Capability to manufacture large-size slabs (3.05 × 1.45 meters) without compromising quality

Most domestic manufacturers struggle to reach these standards, often blending in calcium powder or inflating resin levels—resulting in weaker slabs. At Bevron, we don’t cut corners.

🧼 Care & Cleaning Tips:

- Everyday Cleaning: Use a damp cloth and mild soapy water to clean. Rinse with water and dry with a soft towel.

- Stubborn Stains: For dried stains, gently scrub using a non-abrasive pad.

- Avoid Harsh Chemicals: Stay away from methylene chloride, highly alkaline cleaners, or those containing bleach and abrasives.

- Protect from Heat: Though heat-resistant, sudden temperature changes may cause cracking. Always use trivets or heat pads.

- Use Cutting Boards: Avoid cutting or chopping directly on the slab to maintain its polished finish.

🏡 Ideal Applications:

- Kitchen Countertops & Islands

- Bathroom Vanities

- Commercial Countertops

- Custom Furniture Tops

- Wall Cladding & Flooring

🌱 Eco-Friendly & Safe for Homes

With a high quartz ratio and reduced resin content, this slab not only ensures top performance but is also a green material. Free from radioactive pollution and recyclable, it’s an excellent choice for eco-conscious buyers.

✅ Why Choose Our Black Quartz Slab?

- ✔️ 93–94% Quartz for unmatched durability

- ✔️ Low 6–7% resin for superior structure and minimal deformation

- ✔️ Scratch, stain, and heat-resistant

- ✔️ Maintenance-free with lasting shine

- ✔️ Made with cutting-edge technology rivaling global industry leaders

Invest in the Black Quartz Slab today and experience a fusion of modern elegance, advanced technology, and unmatched performance. Perfect for both residential and commercial settings, it's a smart, stylish, and sustainable choice.

Share