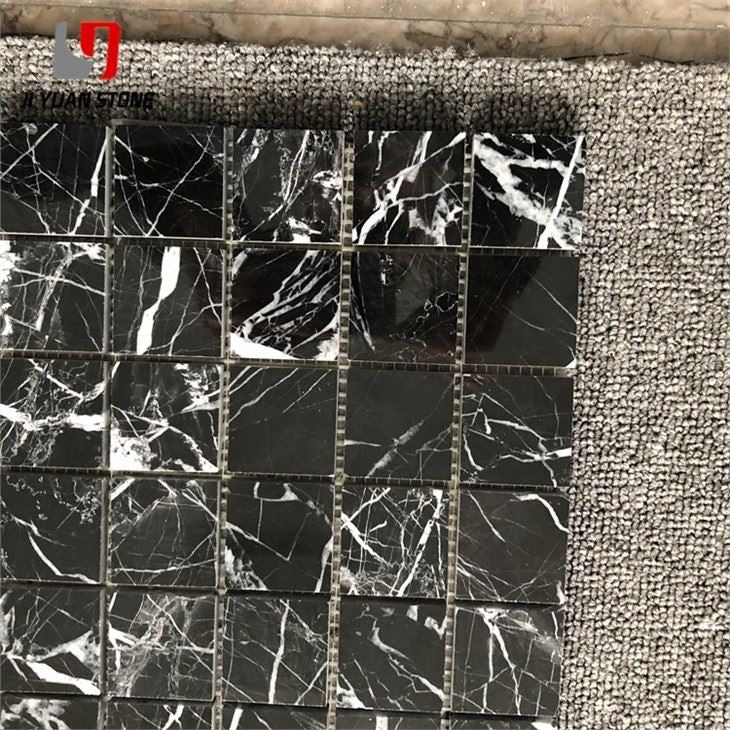

Black Marble Herringbone Mosaic

Black Marble Herringbone Mosaic

Elevate any space with our luxurious Black Marble Herringbone Mosaic. The sleek, natural black marble blends modern style with timeless elegance. Expertly crafted in a herringbone pattern, this mosaic adds depth and visual interest to any room. Upgrade your design with this stunning, high-quality mosaic.

| Feature | Details |

|---|---|

| Material | Natural Marble Stone,Travertine,Limestone |

| Colour | As pictures show or customized |

| Shape | Square, Basketweave, Mini brick, Modern brick, Herringbone, Subway, Hexagon, Octagon, Mixed, Grand fan, Penny round, Hand clipped, Tesserae, Random strip, River rocks, 3D cambered, Pinwheel, Rhomboid, Bubble round, Circle bubble, Stacked, etc... |

| MOQ | Unrestricted |

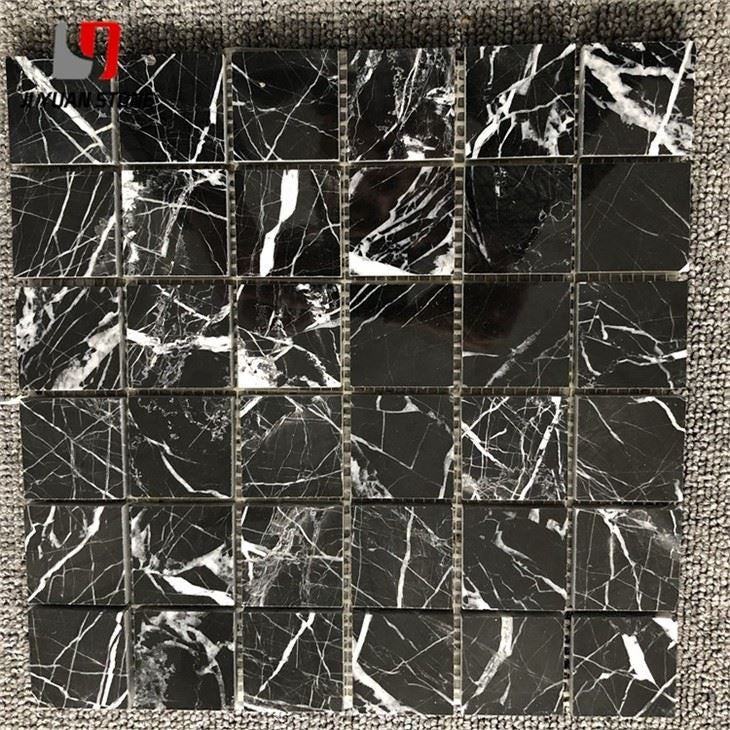

| Regular size | 305 x 305mm, cut-to-size, or according to customer's requirement |

| Thickness | 7mm,10mm |

| Color | Black, grey, yellow, rusty, white, pink, multicolor etc. |

| Finishing | Honed ;split :mushroom ;picked ;stick with cement or glue |

| Package | Carton box and wooden crate,plywood pallet or plywood crate |

| Delivery time | Sample-- abt 2-5days Order ---- abt 10-20days after the deposit. |

| Payment | T/T;30%deposit and 70%blance against copy of B/L; or L/C at sight. |

| Loading port | Guangzhou/Xiamen/Shenzhen/Foshan |

| Min order | 50 square meters |

| Export Market | European, north America, Australia and middle east |

Black Marble Herringbone Mosaic: A Comprehensive Guide

1. Purchasing Black Marble Herringbone Mosaic

When purchasing black marble herringbone mosaic, consider the following key factors:

1.1 Size & Flatness

✔ Ensure that all mosaic particles are of the same specification and size.

✔ Check if the edges are neat and uniform.

✔ Place a single mosaic on a flat surface to verify that it is level.

✔ Inspect the latex layer on the back—it should not be too thick.

1.2 Quality Assessment

✔ Glaze Surface: Touch the glaze to assess its anti-slip properties.

✔ Thickness & Density: The thicker the mosaic, the higher the density and the lower the water absorption rate.

✔ Texture: A smooth, even texture often indicates good quality.

1.3 Water Absorption Test

✔ To ensure durability, check the water absorption rate.

✔ Place water droplets on the back of the mosaic:

- If water remains on the surface, the quality is good.

- If water absorbs quickly, the quality is poor.

Black marble herringbone mosaic is made by cutting, shaping, and polishing natural stone into various shapes and sizes. It is one of the oldest and most traditional mosaic varieties.

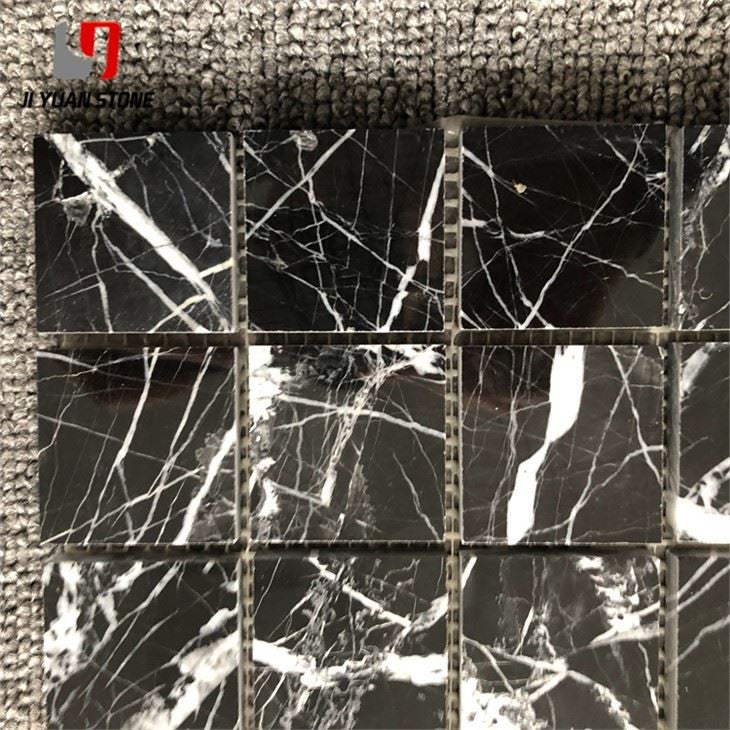

2.1 Characteristics & Appearance

✔ Natural stone texture with a pure, elegant, and timeless aesthetic.

✔ Retains the rustic charm of natural stone while offering unique patterns.

✔ Available in matte and polished finishes.

✔ Comes in a variety of shapes and sizes, including:

- Square

- Strip

- Rounded

- Irregular plane cuts

- Textured surfaces (rough and smooth options)

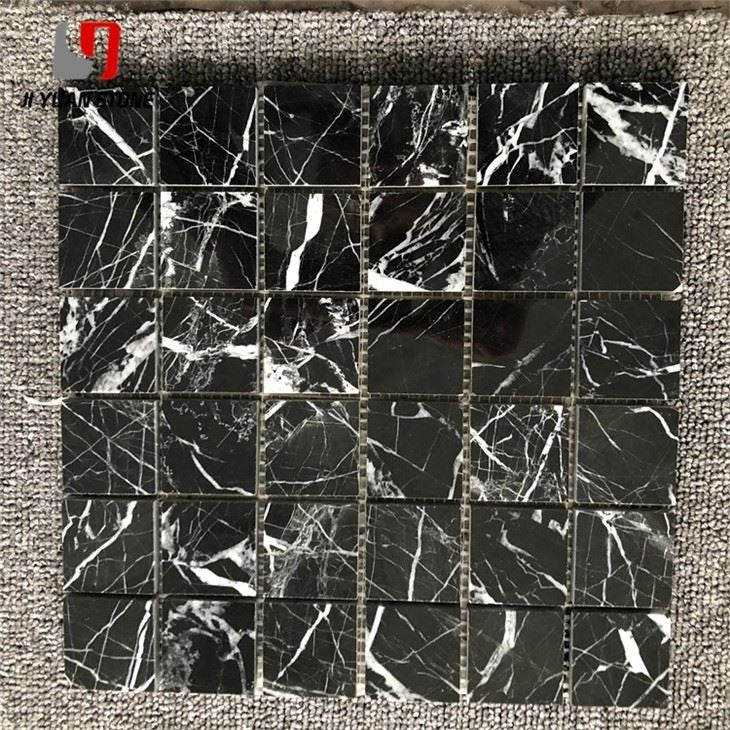

2.2 Production Process

- Machine-cut into small particles.

- Hand-assembled for precision and durability.

- Resistant to fading, peeling, or discoloration over time.

- Ideal for high-end decoration in both interior and exterior applications.

✔ Use specialized stone cleaning agents to protect the natural texture.

✔ Pay attention to cleaning grout lines between small mosaic tiles.

✔ Avoid using harsh chemicals that may damage the stone.

Mosaic products are categorized into six main types:

1️⃣ Mold Mosaics

2️⃣ Small Particle Mosaics

3️⃣ 3D Mosaics

4️⃣ Fracture Surface Mosaics

5️⃣ Mosaic Carpets

6️⃣ Ancient Castle Tiles

4.1 Mold Mosaics & Seam Standards

- Mold mosaics feature seams between tiles for a structured pattern.

- The overall structure consists of standardized small unit blocks arranged in a consistent pattern.

- Blocks are organized based on:

✔ Gap standards

✔ Location alignment

✔ Pattern distribution requirements

4.2 Large-Scale Production Considerations

- Mass-produced mosaics follow standardized designs to meet market demands.

- Large projects require custom cutting and shaping of materials, as waste materials or edging products may not suffice.

- Precision cutting is necessary to ensure seamless installation.

Share