Basalt Paver Tiles

Basalt Paver Tiles

Basalt Paver Tiles – The Ultimate Volcanic Stone for Strength, Endurance, and Innovation

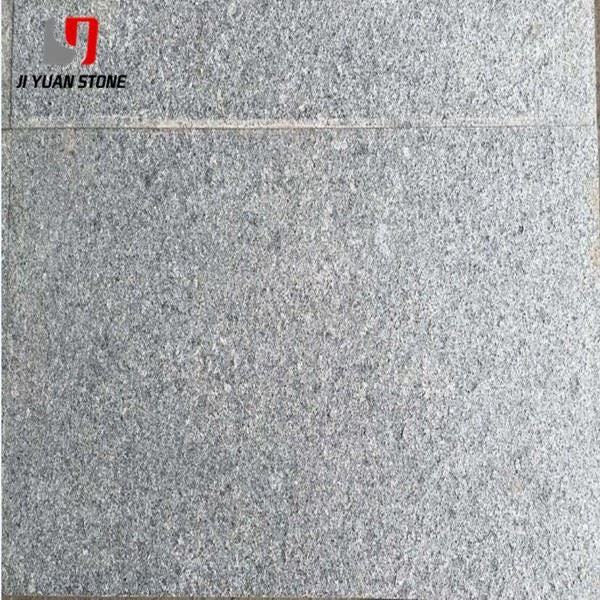

Basalt Paver Tiles are the perfect solution for your outdoor flooring needs. Made with durable basalt, these tiles provide a long-lasting, low maintenance option for your patio, pool deck, or walkway. With a natural, elegant look, these paver tiles are sure to enhance the aesthetic of any outdoor space while providing a safe and sturdy surface.

| Feature | Details |

|---|---|

| Product | Basalt Paver Tiles |

| Material | Black Basalt |

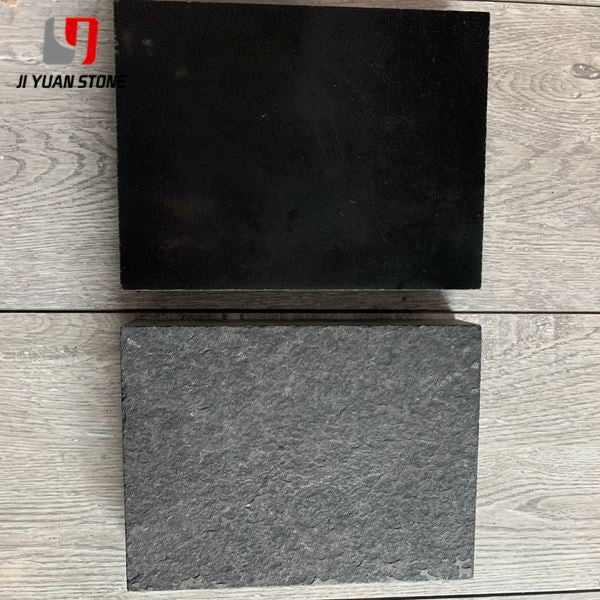

| Surface | Natural Cleft, Saw Cut |

| Thickness | 20mm,30mm etc |

| Finished Products | Floor Tiles, Wall Cladding, Countertops, Windowsills, Special-Shaped Tiles, Small Slabs, Swimming Pool Coping, Stairs, Steps, Wall Panel Paver, Flooring, Veneers, Slabs, Coping Tiles, Cubestone Bathtub etc. |

| Colour | Black |

| Curb/Skirting Stone |

|

| Cube |

|

Basalt paver tiles are forged by nature through a powerful geological process: the cooling and solidification of volcanic magma. Classified as a magmatic rock, basalt forms when magma, with temperatures reaching up to 1200°C, erupts and slowly flows across the landscape. On flat terrain, this magma moves only a few meters per minute, but it accelerates rapidly on steeper slopes. During this journey, it captures water vapor and air bubbles, which upon cooling, give rise to the stone’s dense or foamy structure.

Why Choose Basalt Paver Tiles?

Basalt paver tiles are distinguished by their high density, wear resistance, and superior mechanical performance, making them the perfect material for demanding surfaces like:

- Highways and road repairs

- Airport runways

- Railways

- Industrial floors and pavements

- Lightweight concrete in high-rise buildings

The main mineral components of basalt include silicon dioxide, aluminum oxide, iron oxide, calcium oxide, and magnesium oxide. With a bulk density of 2.8–3.3 g/cm³ and a crushing value between 5–7, basalt is stronger and heavier than granite, limestone, or shale. Its typical colors—black, dark brown, or dark green—convey both elegance and durability.

Versatile Applications in Modern Industry:

- Cast Stone Production: When basalt is melted, cast, and annealed, it forms a cast stone that is tougher than alloy steel and more corrosion-resistant than lead or rubber.

- Steel Casting Lubricant: Finely processed basalt is used in advanced steel manufacturing, increasing the life of casting films.

- Glass Fiber Reinforcement: Basalt can be spun into high-strength glass fibers, which outperform regular fiberglass in both heat and alkali resistance.

- Porous Basalt (Pumice): Used in concrete mixes, this lightweight aggregate improves sound insulation, thermal resistance, and reduces structural weight—perfect for modern construction.

Basalt is not just stone—it's a high-performance geological material with superior strength, corrosion resistance, low water absorption, and low electrical conductivity. It's no exaggeration to call basalt the "big brother of all aggregates."

If you’re planning large-scale construction or infrastructure development, basalt paver tiles are your ultimate foundation for long-lasting performance and architectural excellence.

Share