1

/

of

9

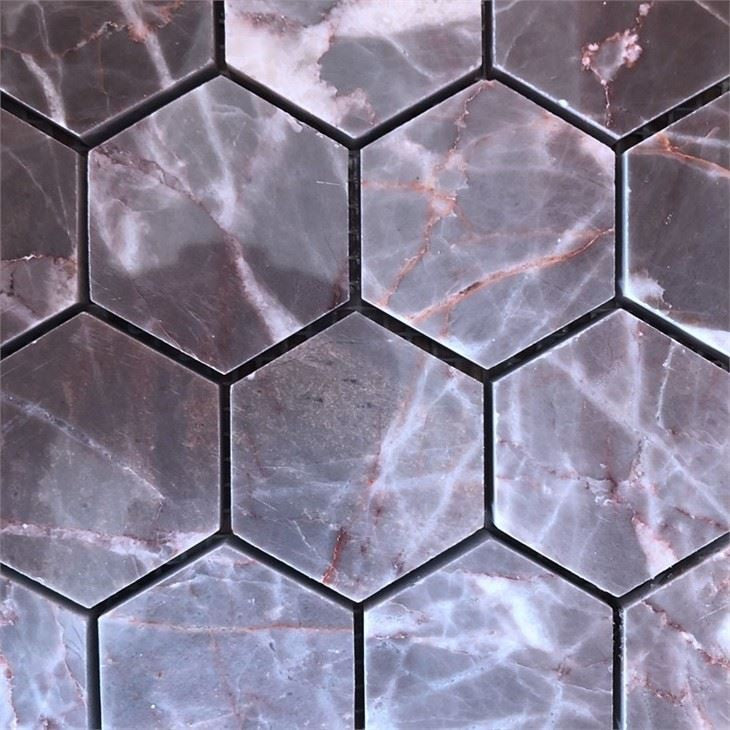

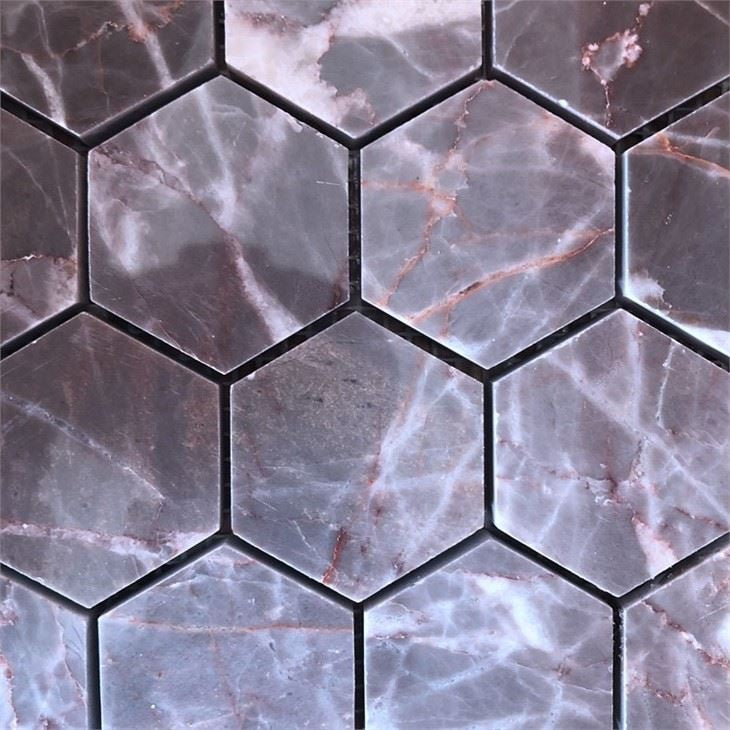

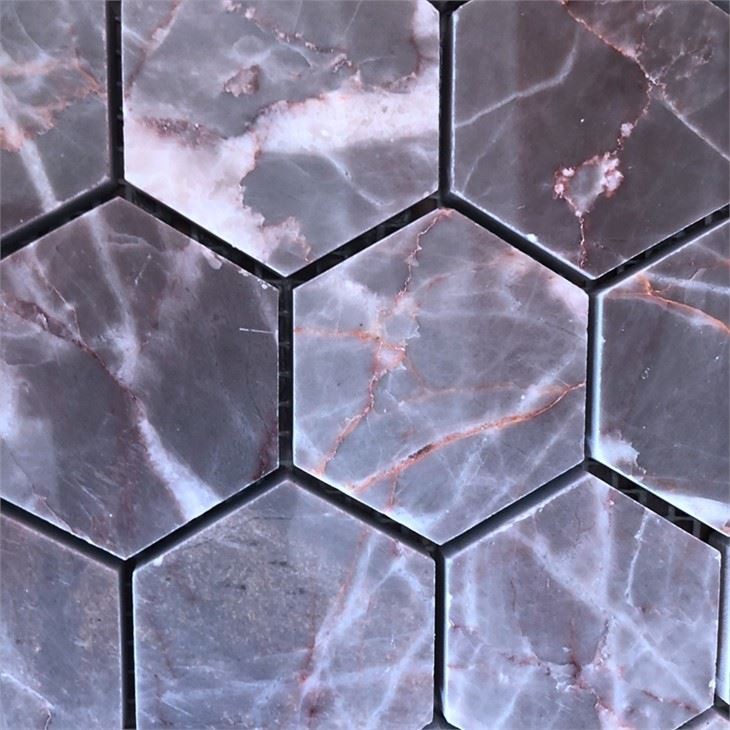

Bardiglio Grey Marble Mosaic

Bardiglio Grey Marble Mosaic

The Bardiglio Grey Marble Mosaic adds sophistication and elegance to any space. Made from high-quality marble, its unique mosaic design creates a stunning visual effect. Perfect for use in kitchens, bathrooms, and other interior spaces, this mosaic offers both durability and timeless beauty.

| Feature | Details |

|---|---|

| Material | Natural Marble Stone,Travertine,Limestone |

| Colour | As pictures show or customized |

| Shape | Square, Basketweave, Mini brick, Modern brick, Herringbone, Subway, Hexagon, Octagon, Mixed, Grand fan, Penny round, Hand clipped, Tesserae, Random strip, River rocks, 3D cambered, Pinwheel, Rhomboid, Bubble round, Circle bubble, Stacked, etc... |

| MOQ | Unrestricted |

| Product Material | Marble |

| Surface Choice | Polished, Honed, Flamed, Antique, Stripped, Bush-hammered, Picked, Sawn, Sandblasted, Tumbled, Brushed, Rough, Lined, Acid-wash, etc. |

| Products Choice | Dry-hangs, Cut-to-Sizes, Panels, Slabs, Tops, Sanitary, Blocks, Stair Steps, Paving, Curbs, Columns, Pillars, Swimming Pool Borders, Tombstone, Sculptures, Fountains, Lanterns, Pots, Tables & Chairs, Meshed Paving, Mosaics etc. |

| Mosaics | 305x305Size(mm) |

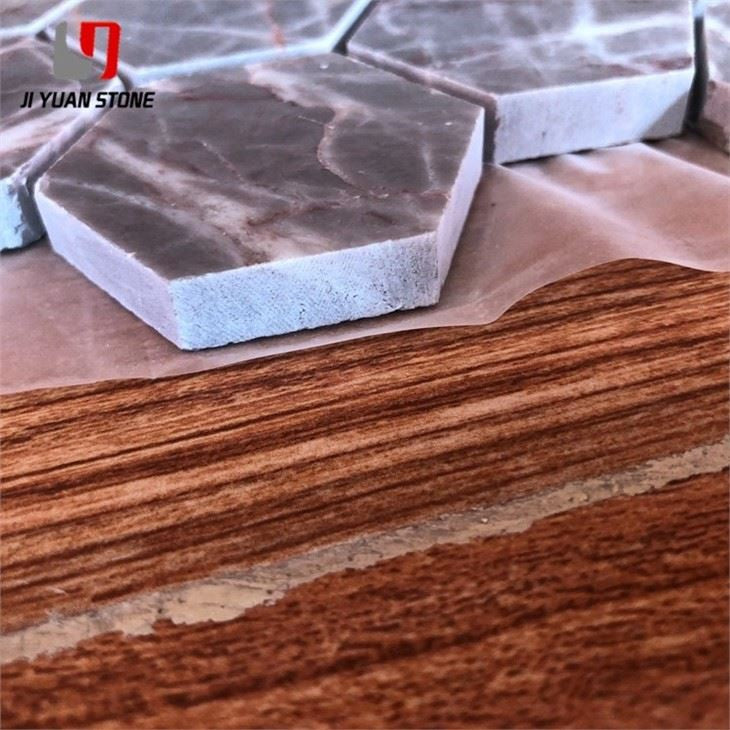

| Thickness(mm) | 10-20 |

| Package | (Poly) Wooden Crate, Pallet, Rain Cloth, Carton & Foam are Our Usual Packing Material, But Different Product Different Pack, Different Pack Different Cost. |

Indoor Common Ground Bardiglio Grey Marble Mosaic Construction Node

Process Steps:

- Preparatory work

- Elastic thread marking

- Trial assembly

- Numbering

- Basic treatment

- Cement grout bonding layer

- Application of special adhesive for stone

- Paving stone

- Filling and wiping joints

- Crystal surface treatment

Key Considerations:

1. Material Composition:

- Dark-colored bardiglio grey marble mosaic: Uses 32.5MPa ordinary Portland cement mixed with medium or coarse sand (mud content ≤ 3%) at a 1:3 ratio.

- Light-colored series: Uses 32.5MPa white cement mortar mixed with white stone chips at a 1:3 ratio.

2. Stone Protection:

- All six sides of the stone must be protected twice (first layer must dry before applying the second layer).

- After removing the back grid, marble should still undergo six-sided protection.

3. Adhesive Application Before Paving:

- Before paving, use a special serrated knife to scrape a layer of adhesive on the back of the stone.

- Allow it to dry, then apply another layer of adhesive before final paving.

- Light-colored stone must use a special binder for white stone.

Indoor Kitchen and Bathroom Floor Stone Construction Node

Scope of Application:

-

Indoor Areas:

- Toilets

- Kitchens (without underfloor heating facilities)

Process Steps:

- Preparatory work

- Spring line marking

- Trial assembly

- Numbering

- Waterproof treatment

- Cement grout bonding layer

- Application of special adhesive for stone

- Paving stone

- Filling and wiping joints

- Crystal surface treatment

Key Considerations:

Waterproofing and Water Storage Test:

- Before paving, conduct a 48-hour water storage test.

- Use flexible waterproof coatings to ensure complete horizontal and vertical waterproofing.

- Water storage test must not be conducted before the waterproof layer is fully dry.

- If the water turns turbid or milky, the waterproof layer has failed and must be redone.

- Waterproof height requirements:

-

-

- Wet areas (e.g., shower room, bathtub): ≥ 1800mm.

- Dry areas: ≥ 300mm.

-

Material Composition:

- Dark-colored bardiglio grey marble mosaic: Uses 32.5MPa ordinary Portland cement mixed with medium or coarse sand (mud content ≤ 3%).

- Light-colored series: Uses 32.5MPa white cement mortar mixed with white stone chips at a 1:3 ratio.

Stone Protection:

- All six sides of the stone must be protected twice (first protection must dry before applying the second).

- Marble must still undergo six-sided protection after the back grid is removed.

Adhesive Application Before Paving:

- Before paving, use a special serrated knife to scrape a layer of adhesive on the back of the stone.

- Allow it to dry, then apply another layer of adhesive before final paving.

- Light-colored stone must use a special binder for white stone.

Share