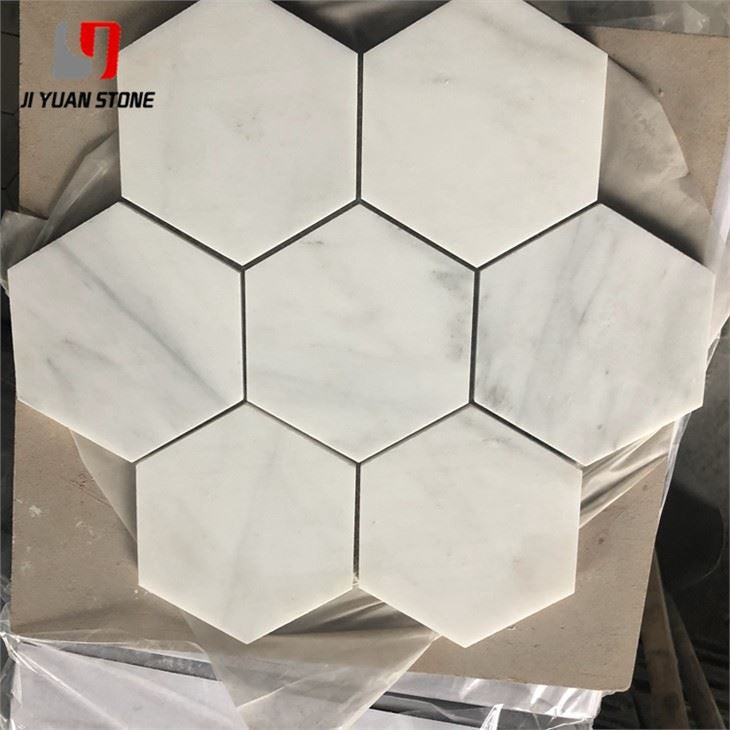

| Material |

Natural Marble Stone,Travertine,Limestone |

| Colour |

As pictures show or customized |

| Shape |

Square, Basketweave, Mini brick, Modern brick, Herringbone, Subway, Hexagon, Octagon, Mixed, Grand fan, Penny round, Hand clipped, Tesserae, Random strip, River rocks, 3D cambered, Pinwheel, Rhomboid, Bubble round, Circle bubble, Stacked, etc... |

| MOQ |

Unrestricted |

| Product Material |

Marble |

| Surface Choice |

Polished, Honed, Flamed, Antique, Stripped, Bush-hammered, Picked, Sawn, Sandblasted, Tumbled, Brushed, Rough, Lined, Acid-wash, etc. |

| Products Choice |

Dry-hangs, Cut-to-Sizes, Panels, Slabs, Tops, Sanitary, Blocks, Stair Steps, Paving, Curbs, Columns, Pillars, Swimming Pool Borders, Tombstone, Sculptures, Fountains, Lanterns, Pots, Tables & Chairs, Meshed Paving, Mosaics etc. |

| Mosaics |

305x305Size(mm) |

| Thickness(mm) |

10-20 |

| Package |

(Poly) Wooden Crate, Pallet, Rain Cloth, Carton & Foam are Our Usual Packing Material, But Different Product Different Pack, Different Pack Different Cost. |