Amethyst Gemstone Slab

Amethyst Gemstone Slab

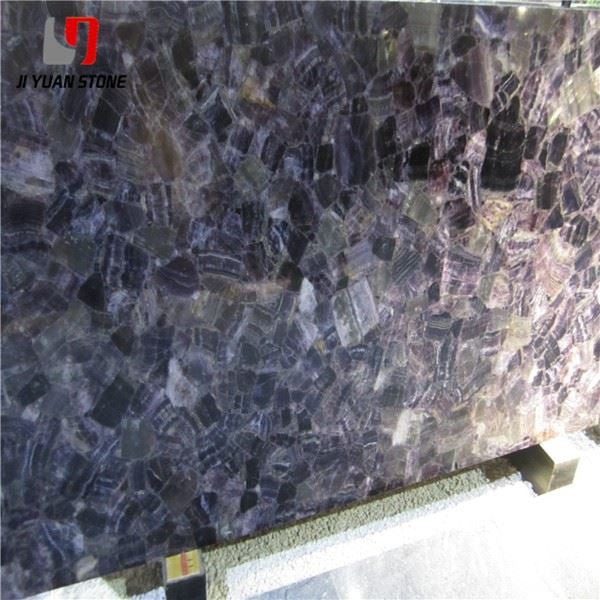

Amethyst Gemstone Slab – Timeless Luxury in Semi-Precious Stone

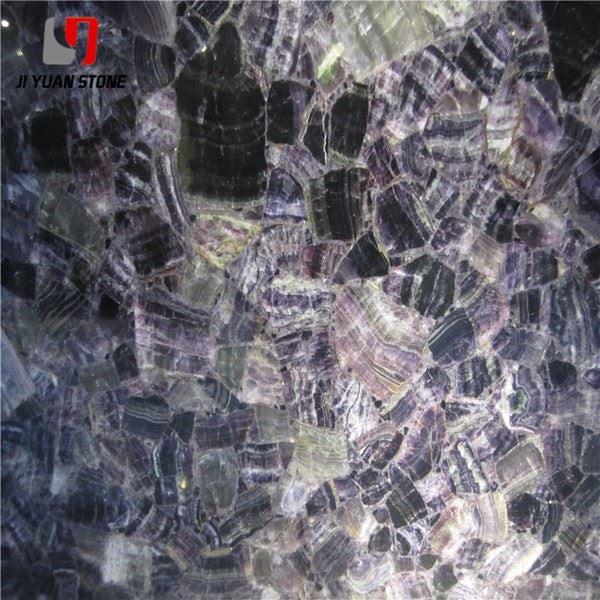

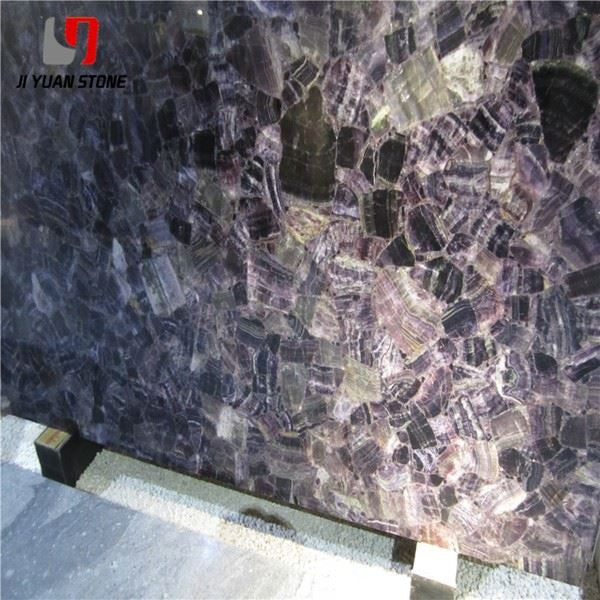

This Amethyst Gemstone Slab boasts a rich and unique deep purple hue, making it a stunning addition to any collection. With its natural formations and durable structure, it is perfect for creating one-of-a-kind jewelry pieces or exquisite decorative pieces. Experience the beauty and versatility of amethyst with this exceptional gemstone slab.

| Feature | Details |

|---|---|

| Product Name | Amethyst Gemstone Slab |

| Surface Finished | Honed,Polished |

| Color | Yellow,Black,White,Red,Purple Wood,Green,Grey,Pink,Rainbow,Pink,Tiger Eye etc |

| Advantage |

(1)Big hardness (2)Very durable (3)Strong corrosion resistance (4) High-temperature resistance (5)Non-toxic and non-radioactive (6)Low cost |

| Usage | Interior & Exterior Decoration. Be widely used in countertops, washing basins, and bar counters, and also suitable for exterior wall panelling, flooring and etc. |

| Small slab |

1800(up)×60-90(up)mm Thickness: 15mm, 18mm, 20mm and etc |

| Big slab |

2400(up)×120(up)mm Thickness: 20mm, 30mm and etc |

| Cut to size |

300 x 300mm, 600 x 600mm, 800 x 800mm and etc Thickness:10mm, 15mm, 18mm, 20mm and etc |

| Kitchen countertop |

96" x 25.5", 108" x 26", 96" x26", 108" x 25" and etc Thickness: 20mm;30mm;20mm+20mm laminate and etc |

| Island top | 96"x36",108"x36",96"x40",72"x36" and etc |

| Vanity top | 31"x22",37"x22",49"x22",61"x22",73"x22" and etc |

| Stair step&riser | 1000-1300x300x20/30mm & 1000-1300x150x20mm |

| Quality control |

(1)Standard Exporting Seaworthy Package ( Inner: plastic film and foam; Outer: Solid Wood crates or pallets.) (2) Color Difference Control (3) Thickness tolerance:+/-0.5mm,+/-1mm |

| MOQ | Welcome Small Trail Orders |

| Sample | Contact Us For Free Samples |

| Payment | T/T, L/C, Escrow, Western Union |

| Delivery | Within three weeks after Confirmation |

Amethyst Gemstone Slabs are renowned for their deep purple hues, crystal-like patterns, and natural elegance. As a semi-precious stone slab, amethyst is perfect for creating luxury countertops, statement walls, flooring, and bespoke furniture. Its durability and natural charm make it a sought-after choice in both residential and commercial interior design projects.

Whether used as a kitchen island, bathroom vanity top, feature wall, or decorative flooring, Amethyst Slabs add unmatched sophistication and a unique sense of style to every space.

Features of Amethyst Gemstone Slabs

- Natural Semi-Precious Stone with striking purple tones and translucent qualities.

- Versatile Applications for countertops, wall cladding, flooring, and furniture.

- Durable & Long-Lasting with resistance to daily wear and scratches.

- Elegant Appeal suitable for luxury homes, hotels, offices, and retail spaces.

General Rules for Laying Out Amethyst Gemstone Slabs

To ensure a flawless installation, follow these professional layout guidelines:

1. Prerequisites for Layout

- Verify that walls and columns have passed inspection and acceptance.

- Ensure that all professional installation pipelines on the base are concealed and accepted.

- Mark the positioning of any unaccepted installations for reference.

2. Measuring and Layout Process

Measure and check the verticality and horizontality of walls and columns.

Depending on the fixing method:

- Wet sticking → Distance from wall/column base to slab surface: ~50mm

- Dry hanging → Distance from wall/column base to slab surface: ~100mm

Mark the finished stone surface position line on the ground.

Perform typesetting based on wall/column dimensions, marking the stone block line to determine the stone processing specifications.

3. Deformation Joints and Seam Considerations

- Preserve the original seismic, expansion, and settlement joints while maintaining finish integrity.

- For large continuous wall areas, confirm deformation joint placement with the design team.

- If not specified, set a 5–8mm deformation joint every 15–25m of continuous wall surface.

4. Seam Alignment for Baseboards

The seam between the baseboard of the wall and the ground cross-circle block should either:

- Be connected through the seam, or

- Be regularly aligned for a uniform and refined appearance.

Why Choose Amethyst Gemstone Slabs?

✅ Rare, semi-precious natural stone with luxurious appeal.

✅ Perfect for wet or dry installation methods.

✅ Adds elegance to countertops, walls, floors & furniture.

✅ Long-lasting durability with proper layout and seam design.

Amethyst Gemstone Slabs not only enhance interiors with their natural beauty but also provide strength and durability when installed with proper layout techniques. From custom furniture and feature walls to flooring and countertops, this semi-precious stone elevates every project into a masterpiece of luxury.

Share