Agate Stone Slab Tile

Agate Stone Slab Tile

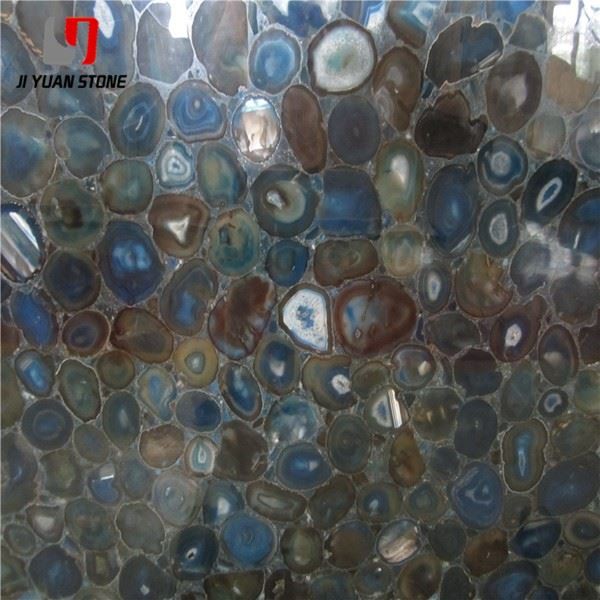

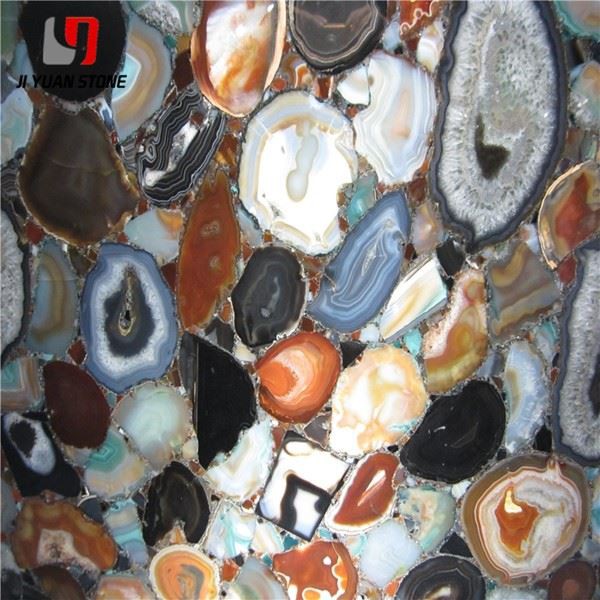

Agate Stone Slab Tiles – Natural Luxury with Structural Precision

Crafted from natural agate stone, these slab tiles add a unique and elegant touch to any space. With each tile showcasing its own one-of-a-kind pattern and coloring, your project is sure to stand out. Perfect for adding a touch of luxury to your home or business design.

| Feature | Details |

|---|---|

| Product Name | Agate Stone Slab Tile |

| Material | Agate Gemstone Semi-precious Stone |

| Surface Finished | Honed,Polished |

| Finished Products | Floor Tiles, Wall Cladding, Countertops, Windowsills, Special-Shaped Tiles, Small Slabs, Swimming Pool, Steps, Wall Panel, Flooring, Veneers, Slabs, Coping Tiles etc. |

| Color | Yellow,Black,White,Red,Purple Wood,Green,Grey,Pink,Rainbow,Pink,Tiger Eye etc |

| Slab Size |

|

| Size |

|

| Package Detail |

1) Slab: plastic inside + strong seaworthy wooden bundle outside 2) tile: foam inside + strong seaworthy wooden crates with reinforced straps outside 3) Countertop: foam inside + strong seaworthy wooden crates with reinforced straps outside |

Elevate your architectural designs with agate stone slab tiles, known for their vibrant patterns, semi-translucent quality, and exceptional durability. Perfect for luxury interiors, agate tiles combine exotic beauty with a crystalline finish that transforms any surface into a statement of sophistication.

These slabs are suitable for floors, walls, steps, and countertops in high-end residential and commercial projects. With expert installation methods, they ensure long-lasting performance in structurally demanding applications.

🛠️ Installation Guide for Agate Stone Slab Tiles

For the best results, choose from the following professional installation techniques based on your project requirements:

1. Direct Bonding Method

In this standard technique, agate stone slab tiles are bonded directly to a flat, firm base layer using specially formulated adhesives.

- Ideal for walls and simple flooring applications

- Requires a clean, dry, and even surface

- Eliminates the need for heavy infrastructure or steel frames

- Simplifies and speeds up the installation process

2. Cantilevered Step Installation

Designed for staircases and floating step designs, this method supports the stone slab via a steel cantilevered frame.

2.1 Thickness Considerations

- Step thickness should be ≤80mm, suitable for spatial constraints

- Base structure: steel frame with flame-retardant board + steel plate

- Agate tile is bonded using agate-specific adhesive, keeping the surface sleek and thin

2.2 Base Layer Construction

Woodworking board or plywood is used instead of mortar

Benefits:

- Can be quickly secured with gun nails and steel plates

- No need for traditional grouting

- Resists impacts better during construction

3. Reinforced Base Layer Method

This is a highly durable and stable installation approach, ideal for high-load applications like steps or countertops.

3.1 Step-by-Step Process

1 . Plant Reinforcement – Enhances steel structure strength

2 . Cement Mortar Leveling – Ensures a flat and level surface

3 . Stone Bonding – Agate tiles are affixed with cement for a firm hold

3.2 Thickness Breakdown

- Agate stone slab tile: 2 cm

- Cement bonding layer: ≥ 0.8 cm

- Mortar base layer: ≥ 1.5 cm

- Total finished thickness: approx. 5 cm

4. Advanced Construction Procedures

Choose one of the following structural methods depending on site conditions:

4.1 Steel Structure Installation Method

Construction Sequence:

- Slot the wall

- Pre-embed steel plates

- Install chemical bolts

- Position and mark the steps

- Weld steel plate and square tubing

- Install agate slab tiles on top

Key Considerations:

- Embedded steel plates serve as structural stress points

- Requires professional structural analysis to determine plate thickness

4.2 Wall-Fixed Installation Method

Construction Sequence:

- On-site layout and planning

- Weld steel plates and square pipes

- Bolt the structure chemically to load-bearing walls

- Add galvanized plates for additional support

- Install the agate slab tile surface layer

Key Considerations:

Requires high wall load-bearing capacity

Not compatible with:

- Aerated light brick walls

- Light steel keel wall systems

🌟 Why Choose Agate Stone Slab Tiles?

- Exquisite natural patterns and crystal clarity

- Ideal for modern, elegant interior and stair applications

- Compatible with direct bonding or advanced structural methods

- Resistant to impact, heat, and moisture

- Adds both artistic and material value to any space

Choose agate stone slab tiles for a unique fusion of natural luxury and engineered strength. Whether you're designing statement stairs, glowing countertops, or timeless walls, these tiles offer unmatched beauty and precision-fit installation options.

Share