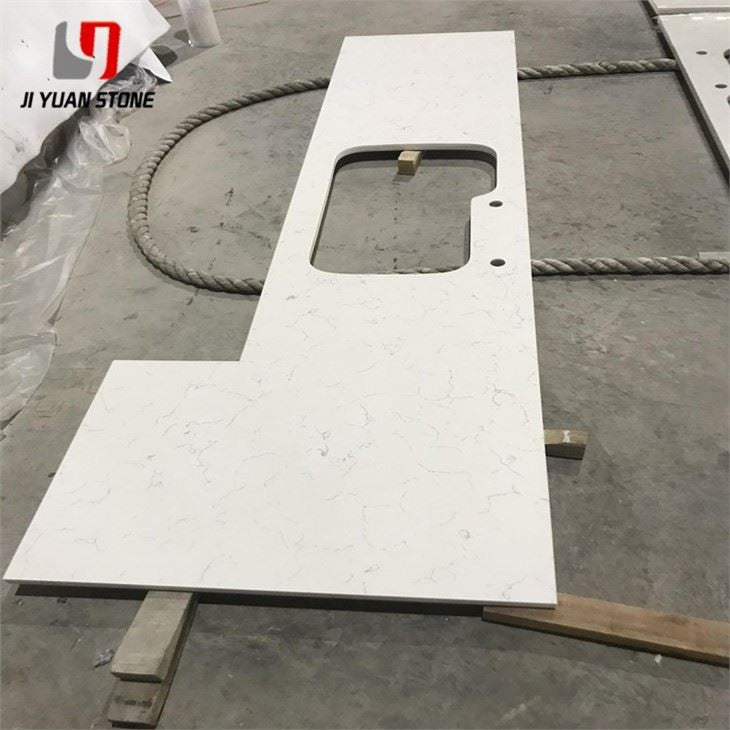

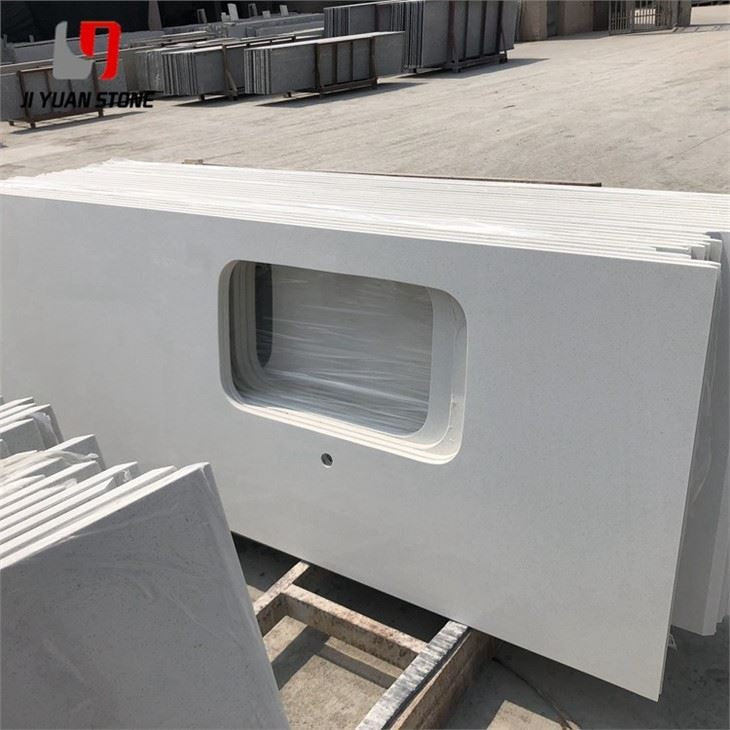

60 Quartz Vanity Top

60 Quartz Vanity Top

60 Inch Quartz Vanity Top – Premium Quality, Durability & Modern Design

Upgrade your bathroom with our 60 Quartz Vanity Top! Made with high-quality quartz material, this vanity top offers durability and style to your space. Its 60-inch size provides ample counter space, making it perfect for any bathroom. Elevate your daily routine with this elegant addition.

| Feature | Details |

|---|---|

| Type | Quartz |

| Material | 93% natural quartz sand + 7% resin |

| Stone Form | Countertops/ Vanity tops |

| Thickness | 12mm; 15mm; 18mm; 20mm; 30mm |

| Standard size |

2794*660mm(110"*26") (size can be customized) |

| Finish | Surface Finish: Polished, Honed, Antique, Abrasive Blasting |

| Molding Edge | Flat, Easted, Stright, Bevel,Bullnose, Full Bullnose, Ogee |

| Resistant | Acid / heat / scatch / staining |

| Color | Black, grey, white Crystal, pure, vein, grain |

| Packing | Plywood bundles, surface protected by plastic film |

The 60 inch quartz vanity top is a stylish and durable choice for modern bathrooms, offering excellent scratch resistance, heat resistance, and easy maintenance. As demand grows worldwide, manufacturers continue to refine production techniques to enhance both the quality and cost-effectiveness of quartz vanity tops.

🔹 Methods to Improve the Quality of 60-Inch Quartz Vanity Tops

With rapid industry development, China’s production of 60-inch quartz vanity tops has surged to nearly 10 million square meters annually, with a large share being exported. The key challenge today lies in improving product quality to meet international standards.

1. Reducing Resin Usage in Artificial Quartz Vanity Tops

Minimizing resin content is crucial for achieving export standards while keeping costs low:

- Cost Efficiency: Every 1% reduction in resin saves about 7 yuan per square meter (based on a 2 cm thickness).

- Export Requirements: Exported quartz vanity tops must contain 93% quartz, limiting resin content to no more than 7%.

Factors Affecting Resin Content

Press Head Pressure:

- At ≤1 kg/cm², resin content rises to 8%-9%, failing export standards.

- At ≥5-10 kg/cm², resin content can be reduced to 6%-7%, meeting requirements.

- Manufacturers can enhance pressure application with cylinders and oil cylinders.

Vibration Frequency of the Press Head:

Proper vibration ensures uniform resin distribution and better slab compaction. Synchronizing vibration with pressing force optimizes results.

Current Industry Challenges:

Many facilities operate presses with ≤1 kg/cm² unit pressure and a frequency of 2900, producing slabs with resin content above the ideal level—8%-9% for coarse-grained slabs and 10%-11% for fine-grained slabs.

2. Optimizing Production Parameters for Better Quality

To achieve higher durability and meet export standards, manufacturers should:

- Modify press machines to increase pressure capacity.

- Fine-tune vibration synchronization with pressing force for consistent results.

- Invest in advanced technology that improves slab density, reduces resin content, and enhances aesthetics.

🔹 Benefits of the 60 Inch Quartz Vanity Top

- Superior Durability: Resistant to scratches, stains, and heat.

- Low Maintenance: Easy to clean with mild soap and water.

- Elegant Appearance: Adds a sleek, modern touch to any bathroom.

- Export-Grade Quality: Meets global standards when produced with optimized methods.

- Cost-Effective Manufacturing: Advanced techniques reduce resin usage and improve overall slab performance.

✅ Conclusion

The 60 Inch Quartz Vanity Top is more than just a bathroom surface—it’s a combination of style, strength, and advanced engineering. By improving production parameters, reducing resin content, and optimizing press technology, manufacturers can deliver quartz vanity tops that meet international quality standards while ensuring long-term durability and stunning aesthetics.

Share